Double-side inclined side hanging type lifting appliance and hoisting equipment with lifting appliance

A lifting equipment and side tilting technology, which is applied in the field of double-sided tilting side-mounted spreaders, can solve the problems of uncompact structure, insensitive movement, and large force on the lock head, so as to improve work efficiency and adaptability to working conditions , Improving the unloading rate of materials and preventing the lock from being stressed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0041] According to a first embodiment of the present invention, there is provided a double-sided inclined side-mounted spreader:

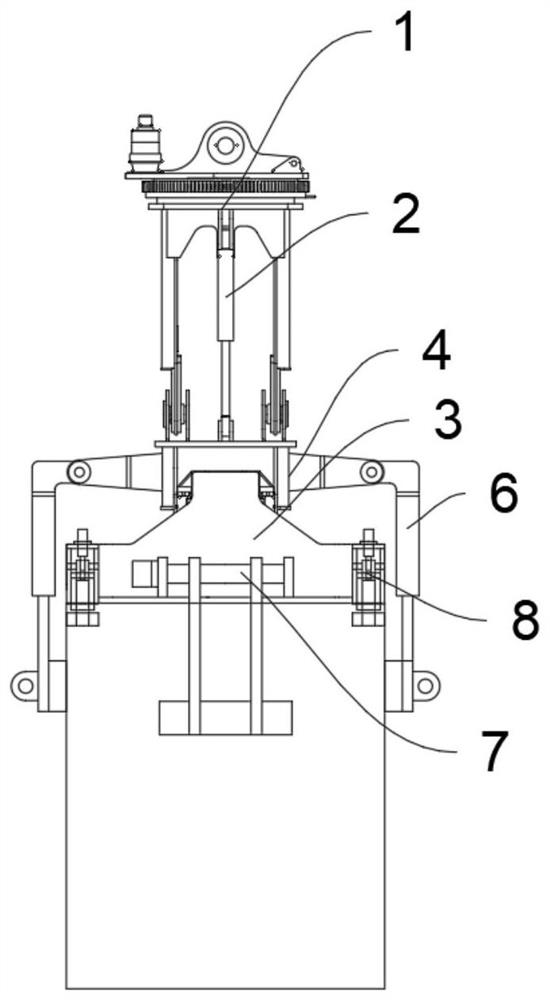

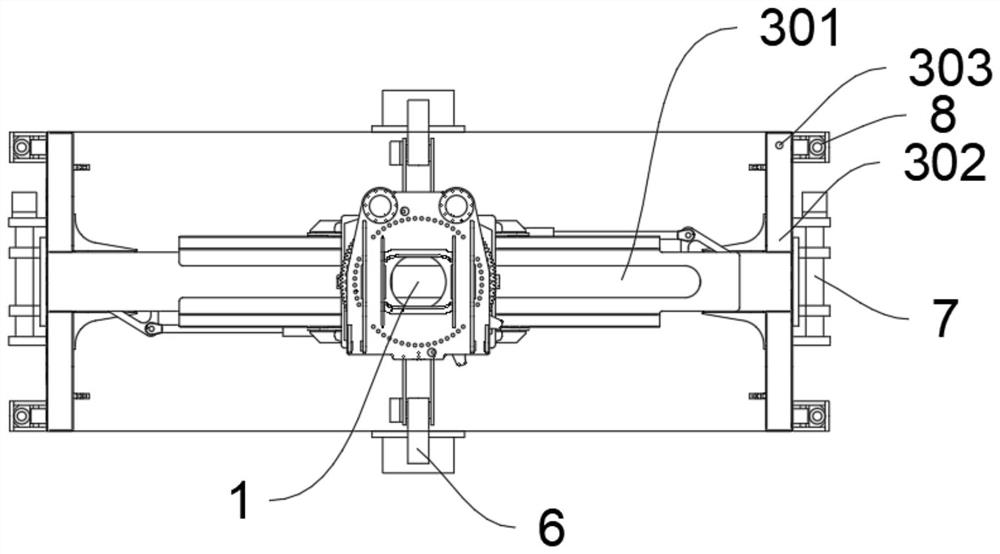

[0042] A double-sided inclined side-hanging spreader, the spreader includes: a turntable assembly 1 whose upper end is used to connect with lifting equipment; a bracket assembly 4 whose upper end is hinged to the lower end of the turntable assembly 1; The crossbeam assembly 3 in the bracket assembly 4, the crossbeam assembly 3 can move relative to the bracket assembly 4, the crossbeam assembly 3 is used to connect with the container; The tipping mechanism 2 on both sides of the hinge between the lower end of the lower end and the bracket assembly 4, the tipping mechanism 2 is used to control the rotation of the bracket assembly 4 relative to the turntable assembly 1; one end is connected to the beam The assembly 3 is connected, and the other end is connected with the side shift mechanism 5 of the bracket assembly 4, and the side shift mechanism 5 ...

Embodiment 1

[0071] A double-sided inclined side-hanging spreader, the spreader includes: a turntable assembly 1 whose upper end is used to connect with lifting equipment; a bracket assembly 4 whose upper end is hinged to the lower end of the turntable assembly 1; The crossbeam assembly 3 in the bracket assembly 4, the crossbeam assembly 3 can move relative to the bracket assembly 4, the crossbeam assembly 3 is used to connect with the container; The tipping mechanism 2 on both sides of the hinge between the lower end of the lower end and the bracket assembly 4, the tipping mechanism 2 is used to control the rotation of the bracket assembly 4 relative to the turntable assembly 1; one end is connected to the beam The assembly 3 is connected, and the other end is connected with the side shift mechanism 5 of the bracket assembly 4, and the side shift mechanism 5 is used to control and adjust the relative position of the beam assembly 3 and the bracket assembly 4, The lateral movement mechanis...

Embodiment 2

[0073] Example 1 is repeated, except that the bracket assembly 4 includes: a bracket body 401 hinged to the lower end of the turntable assembly 1 , and a first hinge for being hinged to the dumping mechanism 2 is provided on the bracket body 401 . Hinged support 405, the first articulated support 405 is located on both sides of the load-bearing hinge axis CZ1; the first leg group 402 connected to the bracket body 401 at the upper end, the first leg group 402 Located on one side of the load-bearing hinge axis CZ1, the legs of the first leg group 402 are separately arranged on both sides of the beam assembly 3; the upper end of the second leg group 403 connected to the bracket body 401 , the second outrigger group 403 is located on the other side of the load-bearing hinge axis CZ1, and the outriggers of the second outrigger group 403 are separately arranged on both sides of the beam assembly 3; The lower end of the outrigger set 402 and the lower end of the second outrigger set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com