High-pressure natural gas long pipe trailer for four-stage gas filling

A technology for natural gas and high-pressure gas cylinders, which is applied in pipeline systems, gas/liquid distribution and storage, bottled transportation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

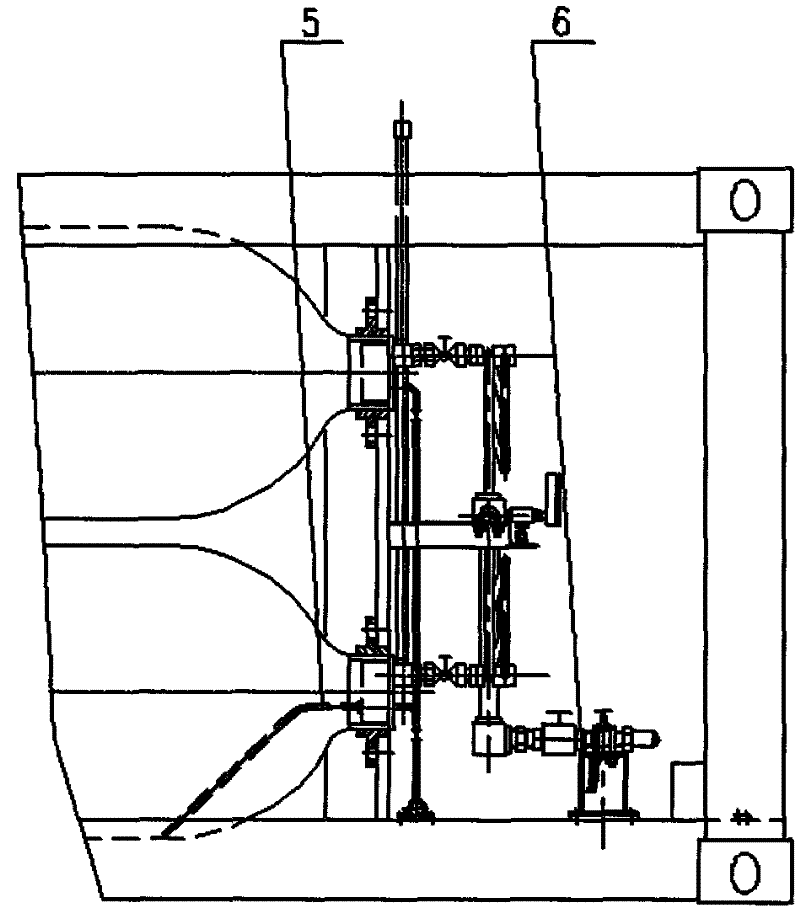

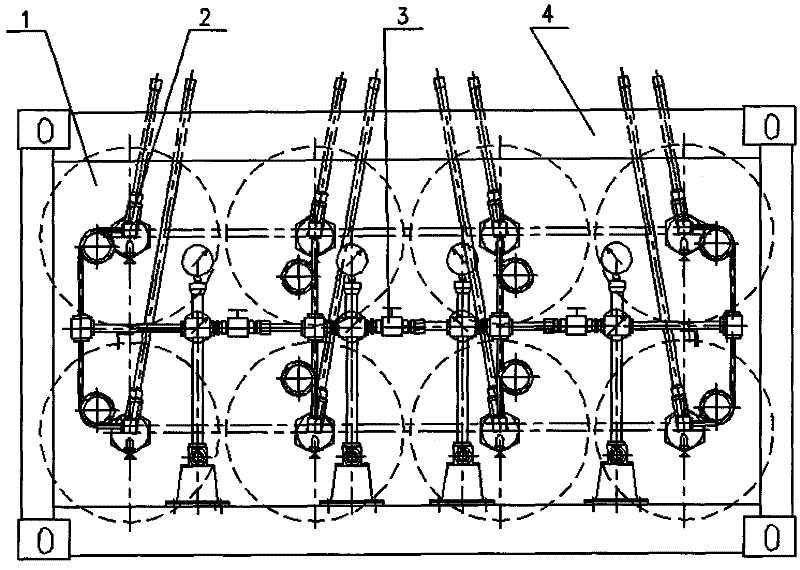

[0017] Figure 1 to Figure 5 It is a specific embodiment of the present invention.

[0018] The specific implementation and application of the four-stage gas filling includes a high-pressure gas cylinder 1, a safety relief device 2, an air inlet and outlet pipeline 3, a frame 4, a sewage discharge device 5, and a bracket 6. The safety release device 2 can safely protect the high-pressure gas cylinder 1. When the pressure of the high-pressure gas cylinder 1 is greater than the set pressure, it will automatically explode to automatically protect the high-pressure gas cylinder 1. The sewage discharge device 5 can regularly discharge the high-pressure gas cylinder The residual liquid in 1 can effectively prevent the stress corrosion of hydrogen sulfide in the residual liquid inside the high-pressure gas cylinder, and can also play a role in protecting the high-pressure gas cylinder 1.

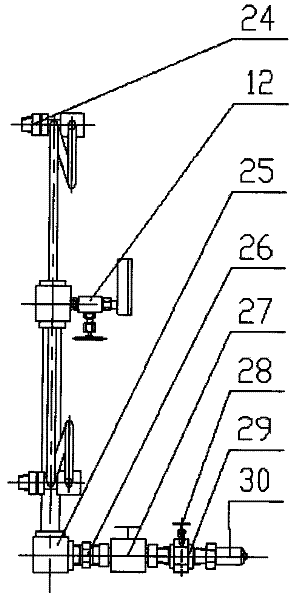

[0019] The specific structure of the air inlet and outlet pipeline 3 is as follows: image 3 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com