Polyethylene pipe broken material or drop material sorting and separating device

A technology of polyethylene pipe and separation device, which is applied in the direction of solid separation, magnetic separation, and separation of solids from solids by air flow, etc., which can solve the problems of inability to separate and distinguish substances, increase production costs, and difficulty in recycling falling materials, and achieve Improvement of wall thickness instability, reduction of production cost, significant effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

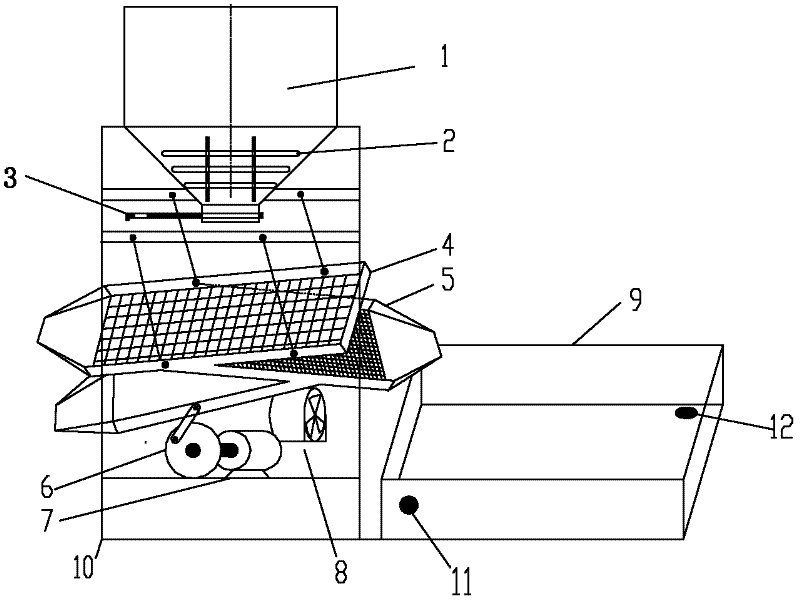

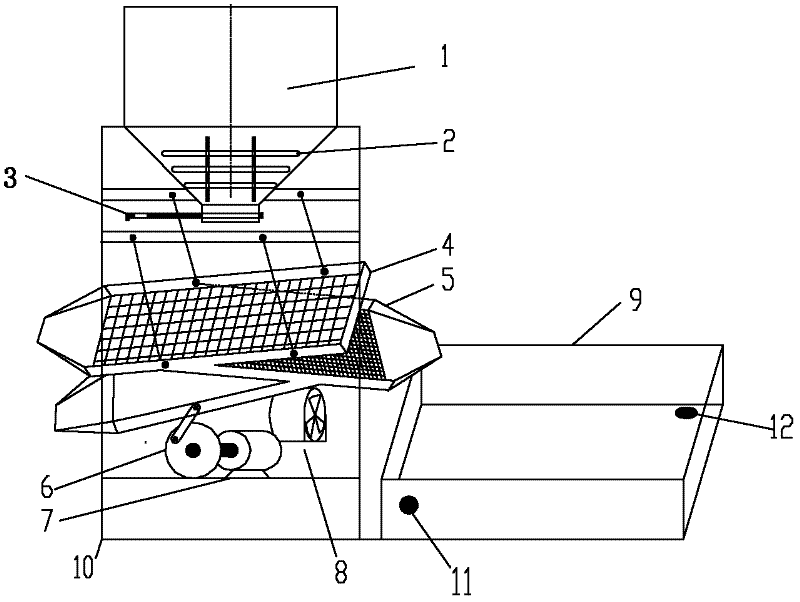

[0015] Example 1 Screening of ground material

[0016] Now in conjunction with the accompanying drawings to illustrate, the polyethylene floor material is added to the hopper 1, and the feeding speed controller 3 is turned on. The floor material starts to flow downward slowly due to its own weight, and the flowing material passes through the magnetic frame 2 to remove the iron present in the material. Metal impurities such as chips enter the primary screen 4, and the eccentric shaft is driven by the motor 7 to make the screens 4 and 5 reciprocate. Since the screen of the primary screen 4 is relatively thick, some strips, rods, stones, firewood, etc. After the garbage is blocked and cannot pass through, it will be discharged from the left outlet, and the unblocked materials will be further separated through the secondary screen 5. Since the secondary screen 5 is finer, the sand, dust, and stones with finer particle sizes Impurities such as non-magnetic metals are sieved and dis...

Embodiment 2

[0017] Example 2 Screening of crushed material

[0018] Now with reference to the accompanying drawings, the polyethylene crushed material is put into the feeding hopper 1, and the feeding speed controller 3 is turned on. The crushed material starts to flow downward slowly due to its own weight, and the flowing material passes through the magnetic frame 2 to remove the iron existing in the material. Metal impurities such as swarf enter the primary screen 4, and the eccentric shaft is driven by the motor 7 to make the screens 4 and 5 reciprocate. Since the screen of the primary screen 4 is relatively thick, some strips, filaments, large particles, etc. Irregular broken materials are blocked and cannot pass through and are discharged from the left outlet. The unblocked materials are further separated through the secondary screen 5. Since the secondary screen 5 is finer, the particle size is finer and the chip dust, filamentous Irregular broken materials such as strips, strips, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com