Flash butt welding machine

A technology for butt welding machines and chains, applied in welding equipment, resistance welding equipment, welding/welding/cutting items, etc., it can solve the problems of slow response speed, cumbersome feeding mechanism, and many components, etc., and achieves an improved response speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

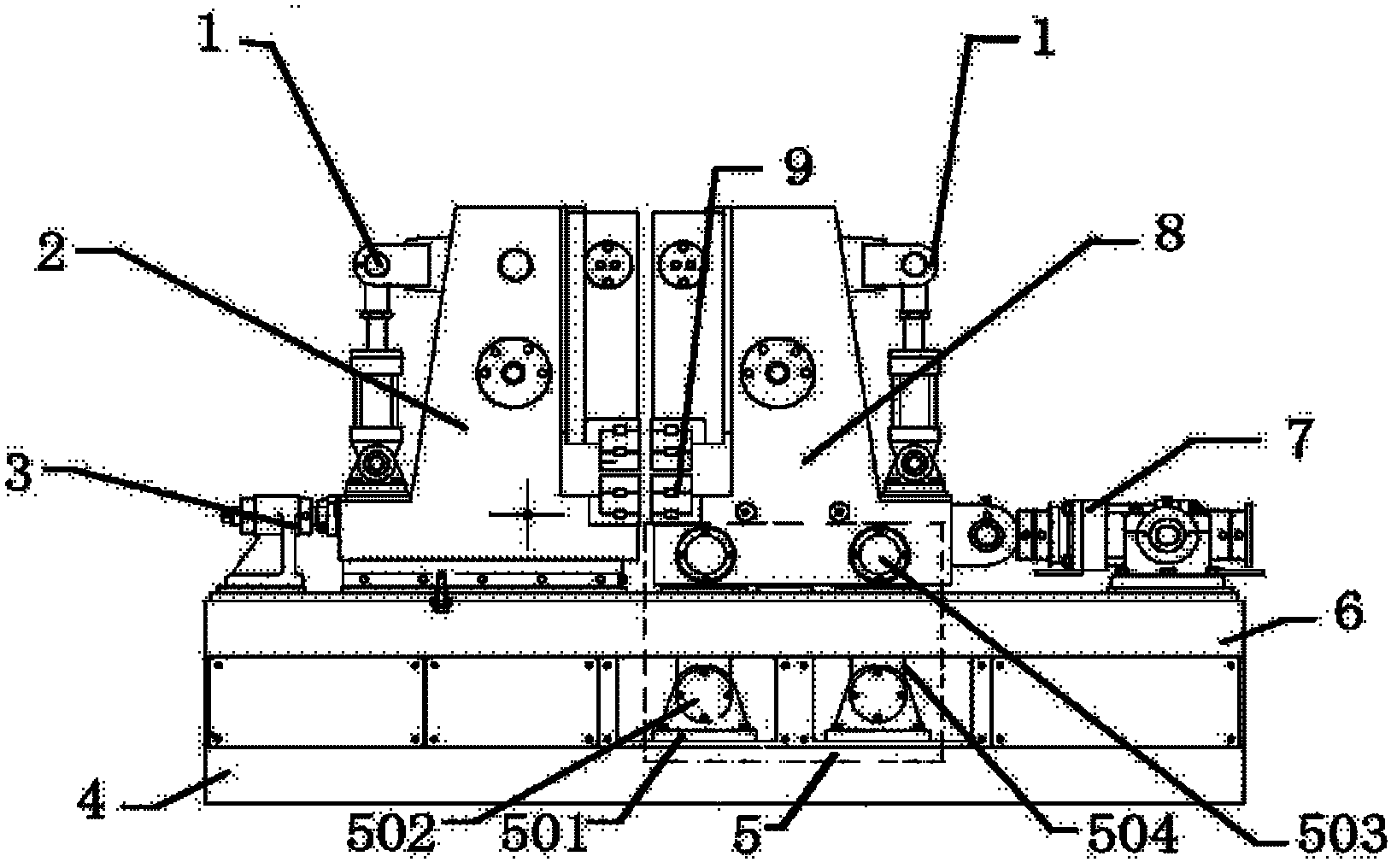

[0012] Such as figure 1 Shown, the present invention support 4, frame 6, send drive device 7, welding control system, fixed workbench 2, movable workbench 8. Left and right two sliding guide rails are installed on the table top of the frame 6 of the main engine, and the fixed workbench 2 and the movable workbench 8 are respectively housed on the left and right two guide rails. Clamping mechanism 1 is arranged, and this clamping mechanism 1 comprises oil cylinder piston rod, clamping slide block, and oil cylinder piston rod moves up and down through lever and drives clamping slide block to move up and down, and the workpiece to be welded is clamped. The upper and lower electrodes and the upper and lower conductors 9 are installed on the frame of the fixed workbench 2 and the movable workbench 8 according to the conventional design. The bottom of the movable table 8 is provided with a double pendulum feeding mechanism 5, which includes an upper swing shaft 503 and a lower swing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com