Tension mechanism of wire drawing machine

The technology of a tension mechanism and a wire drawing machine, which is applied in the field of metal product production, can solve the problems of low production efficiency, broken wire stacking, difficulty in finding and overhauling, etc., and achieves the effect of ingenious structure and balanced tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific drawings and embodiments.

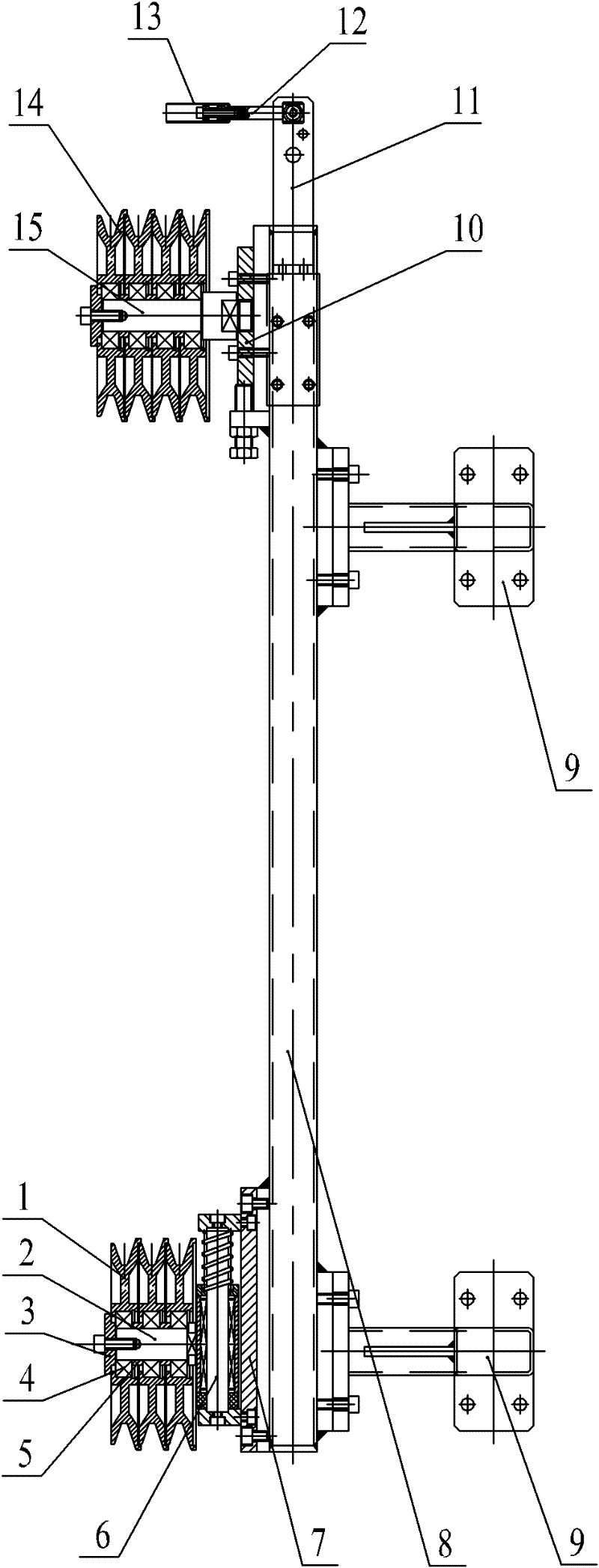

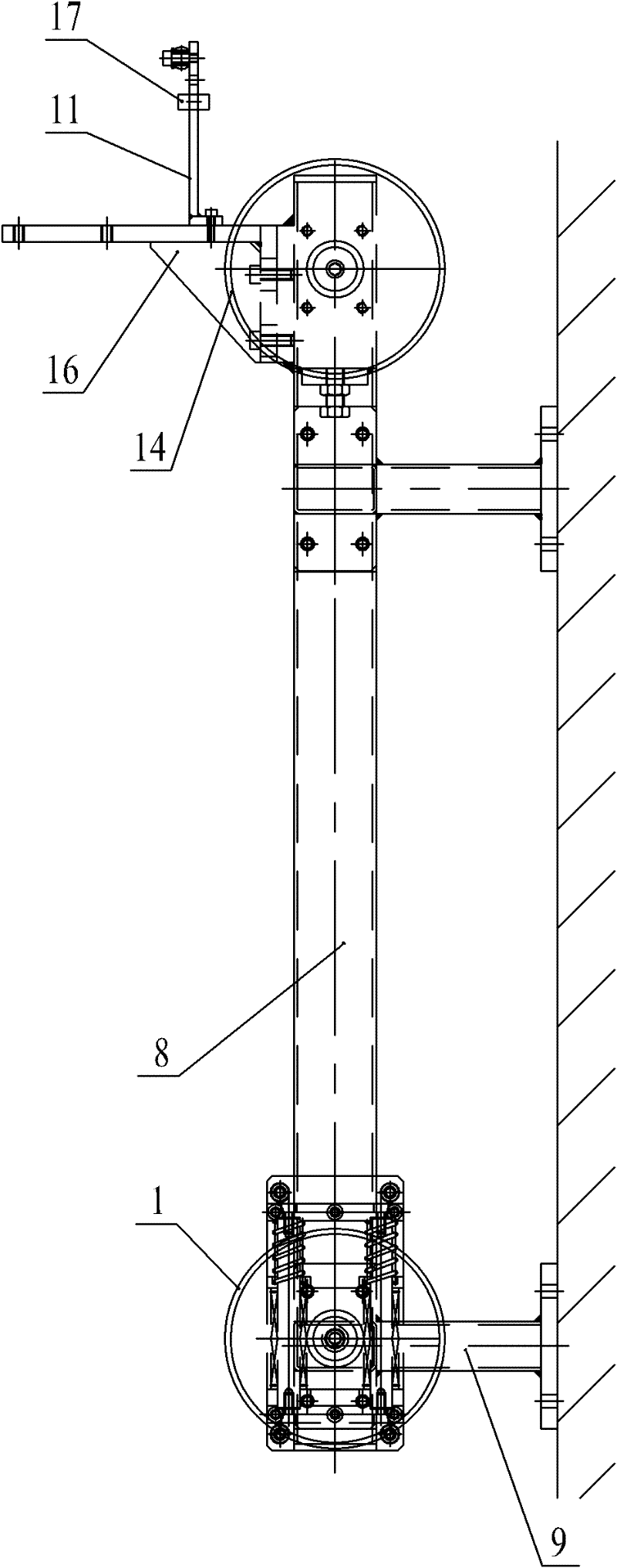

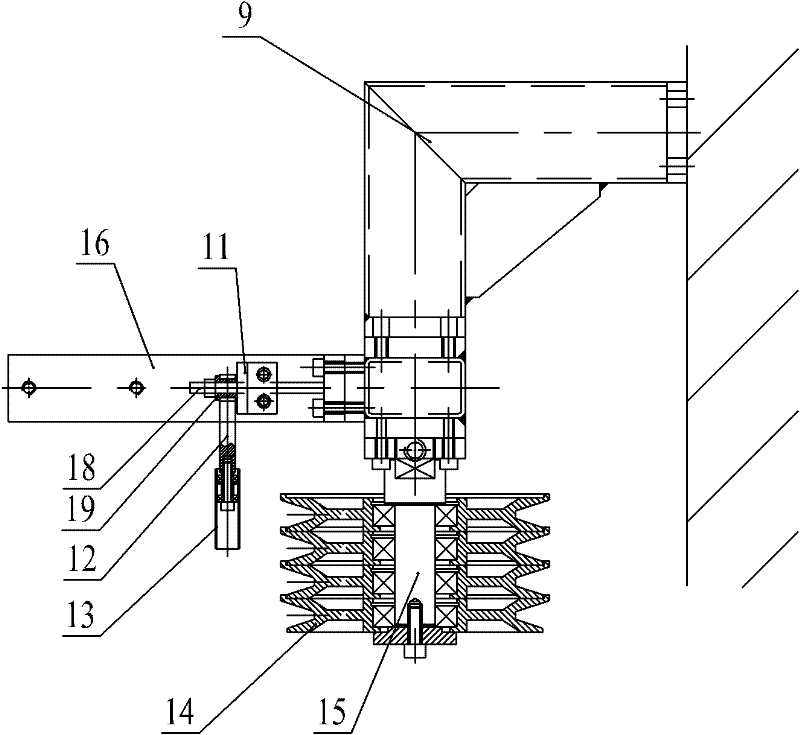

[0017] As shown in the figure, the tension mechanism of the wire drawing machine is mainly composed of a lower roller 1, a lower axle 2, a washer 3, a bearing 4, a retaining ring 5, an elastic buffer mechanism 6, a lower fixing plate 7, a column 8, a bracket 9, and an upper fixing plate. Plate 10, small bracket 11, small shaft 12, roller sleeve 13, upper roller 14, upper wheel shaft 15, side support 16, sensor 17, bearing pin screw 18 and cover 19 and other components.

[0018] Such as Figure 1~Figure 3 As shown, the support 9 is fixed on the frame of the wire drawing machine by screws, and the column 8 is fixed on the support 9 by screws; the lower end of the column 8 is fixed with a lower fixing plate 7 by screws, and an elastic buffer mechanism is installed on the lower fixing plate 7 6. The lower wheel shaft 2 is installed on the elastic buffer mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com