Method for jet-plating antimicrobial coating on nano mirror surface

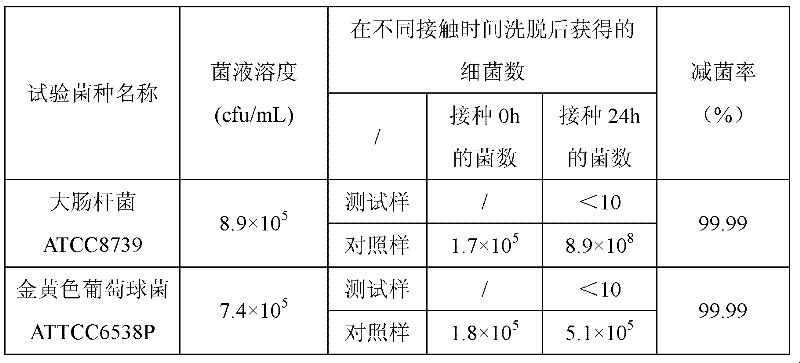

A technology of nano-mirror surface and antibacterial coating, which is applied to the device, coating, special surface and other directions of coating liquid on the surface, which can solve the problems of poor continuous antibacterial effect and insufficient wear resistance of the coating, and achieve long antibacterial effect , low cost, high antibacterial efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Carrying out the antimicrobial coating method of nano-mirror surface spraying on the PP plastic surface, comprises the following steps:

[0023] 1) PP plastic surface modification treatment: Flame treatment is carried out on the PP plastic surface to remove grease and modify the surface to improve the bonding force with the primer.

[0024] 2) Spray UV-curable (UV) primer layer; use a spray gun to spray a 30 μm thick UV-curable primer layer on the surface of PP plastic that has undergone surface modification, and then send it to an infrared oven for leveling of the spray paint film layer 1. Drying, the drying temperature can be 50°C, and the drying time is 10 minutes. After drying, the spray paint film layer is irradiated and cured in an ultraviolet light curing furnace for 45 seconds.

[0025] 3) Surface sensitization and activation treatment: Spray sensitizing activation solution on the PP plastic surface sprayed with a primer layer with a spray gun, then spray wash w...

Embodiment 2

[0033] Carrying out the antimicrobial coating method of nano-mirror surface spraying on the ABS plastic surface, comprises the following steps:

[0034] 1) ABS plastic surface modification treatment: Atmospheric pressure plasma treatment and electrostatic dust removal treatment are carried out on the ABS plastic surface to remove grease and modify the surface to improve the bonding force with the primer.

[0035] 2) Spray ultraviolet curing (UV) primer layer; use a spray gun to spray a 10 μm thick UV curing primer layer on the surface of the surface-modified ABS plastic, and then send it to an infrared oven for leveling of the spray paint film layer , Drying, the drying temperature can be 60°C, and the drying time is 8 minutes. After drying, the spray paint film layer is irradiated and cured in an ultraviolet light curing furnace for 30 seconds.

[0036] 3) Surface sensitization, activation treatment: Spray sensitization activation liquid on the ABS plastic surface of the spra...

Embodiment 3

[0041] Carrying out the antimicrobial coating method of nano-mirror surface spraying on PC plastic surface, comprises the following steps:

[0042] 1) PC plastic surface modification treatment: carry out atmospheric pressure plasma treatment and electrostatic dust removal treatment on the PC plastic surface to remove grease and modify the surface to improve the bonding force with the primer.

[0043] 2) Spraying ultraviolet light curing (UV) primer layer; use a spray gun to spray a 20 μm thick ultraviolet light curing primer layer on the PC plastic surface after surface modification, and then send it into an infrared oven for leveling of the spray paint film layer , Drying, the drying temperature can be 70°C, the drying time is 5min, and the dried spray paint film layer is irradiated and cured in the ultraviolet light curing furnace for 10s.

[0044] 3) Surface sensitization, activation treatment: Spray sensitization activation solution on the PC plastic surface of sprayed pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com