Synergistic agent for flue gas desulfurization process adopting wet limestone-gypsum method and application thereof

A desulfurization process and synergist technology, which are applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., to achieve the effects of simple operating conditions, convenient operation, and good capacity expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

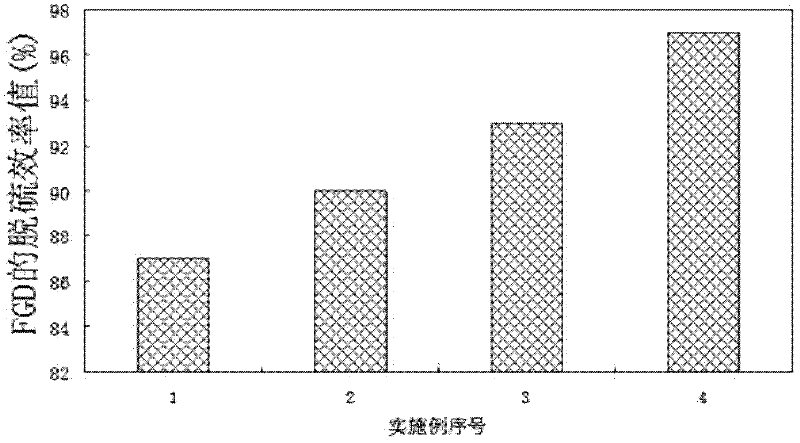

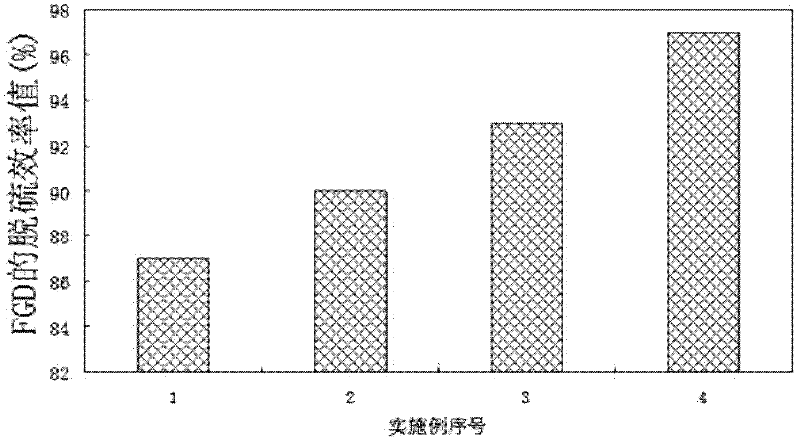

[0020] Preparation and use of embodiment 1 synergist of the present invention

[0021] For the flue gas desulfurization device of a 300MW unit in a coal-fired power plant, the slurry volume of the absorption tower is 1250m 3 , when the synergist is added, the desulfurization efficiency of the system is about 87%. 0.37t borax (containing 95% Na 2 B 4 o 7 10H 2 O) add 30m 3 In the pit of the absorption tower, add water and stir for 30 minutes to make a suspension of the synergist; use the pit pump to inject the synergist into the absorption tower, wash the pit repeatedly for 3 times and add it to the absorption tower, then absorb Tower, Na 2 B 4 o 7 The concentration is 7.30×10 -4 mol L -1 . Use the flue gas online monitor to export SO to the system 2 The concentration and desulfurization efficiency were tested, and the results showed that when the synergist was added to the absorption tower for 2 hours, the desulfurization efficiency of the system increased to about...

Embodiment 2

[0022] Preparation and use of embodiment 2 synergist of the present invention

[0023] For the flue gas desulfurization device of a 300MW unit in a coal-fired power plant, the slurry volume of the absorption tower is 1250m 3 , when the synergist is added, the desulfurization efficiency of the system is about 87%. 0.73t borax (containing 95% Na 2 B 4 o 7 10H 2 O) add 30m 3 In the pit of the absorption tower, add water and stir for 30 minutes to make a suspension of the synergist; use the pit pump to inject the synergist into the absorption tower, wash the pit repeatedly for 3 times and add it to the absorption tower, then absorb Tower, Na 2 B 4 o 7 The concentration is 1.46×10 -3 mol L -1 . Use the flue gas online monitor to export SO to the system 2 The concentration and desulfurization efficiency were tested, and the results showed that when the synergist was added to the absorption tower for 2 hours, the desulfurization efficiency of the system increased to about...

Embodiment 3

[0024] Preparation and use of embodiment 3 synergist of the present invention

[0025] For the flue gas desulfurization device of a 300MW unit in a coal-fired power plant, the slurry volume of the absorption tower is 1250m 3 , when the synergist is added, the desulfurization efficiency of the system is about 87%. 2.19t borax (containing 95% Na 2 B 4 o 7 10H 2 O) add 30m 3 In the pit of the absorption tower, add water and stir for 30 minutes to make a suspension of the synergist; use the pit pump to inject the synergist into the absorption tower, wash the pit repeatedly for 3 times and add it to the absorption tower, then absorb Tower, Na 2 B 4 o 7 The concentration is 4.38×10 -3 mol L -1 . Use the flue gas online monitor to export SO to the system 2 The concentration and desulfurization efficiency were tested, and the results showed that when the synergist was added to the absorption tower for 2 hours, the desulfurization efficiency of the system increased to about...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com