PDP (plasma display panel) discharge electrode and manufacturing method thereof

A discharge electrode and manufacturing method technology, applied in the direction of gas discharge electrode, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problem of low brightness of the display screen, increase the surface area, improve the brightness effect, and increase the ignition area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

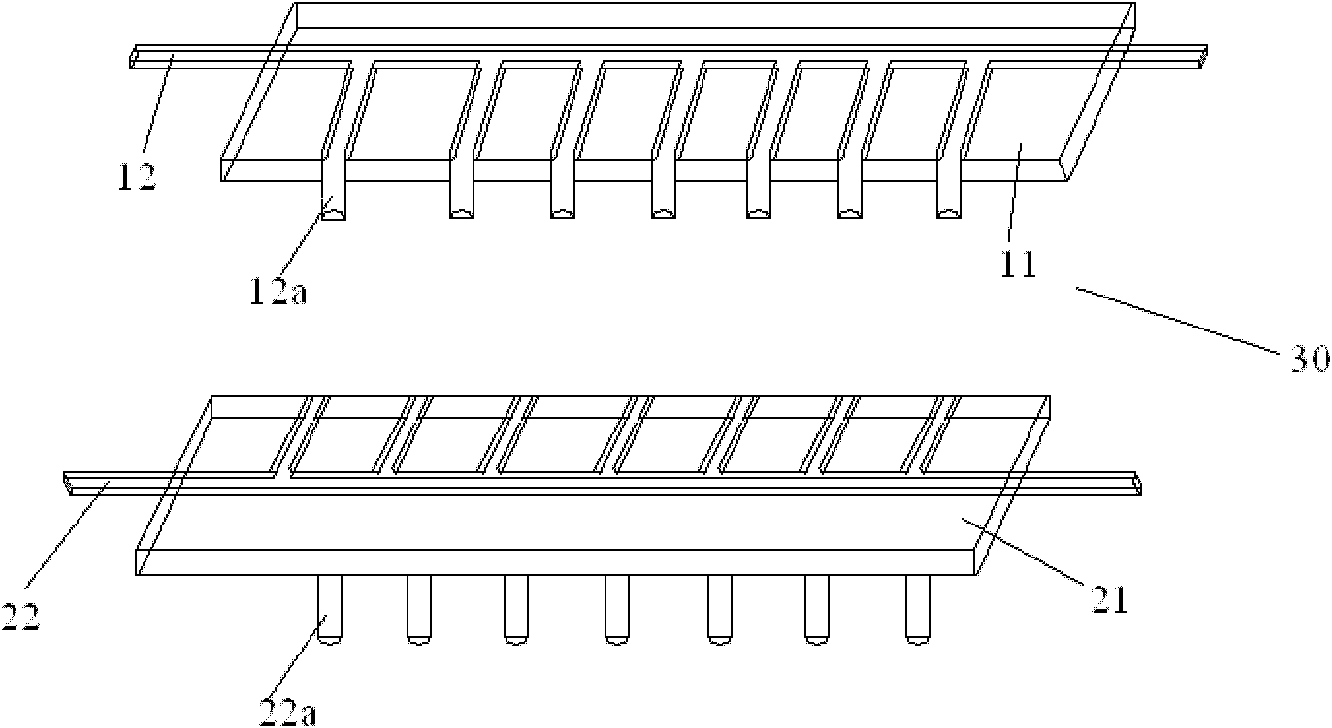

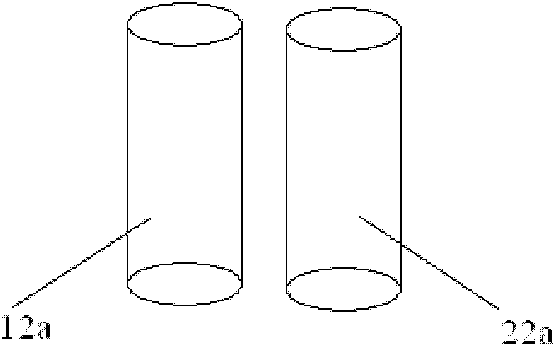

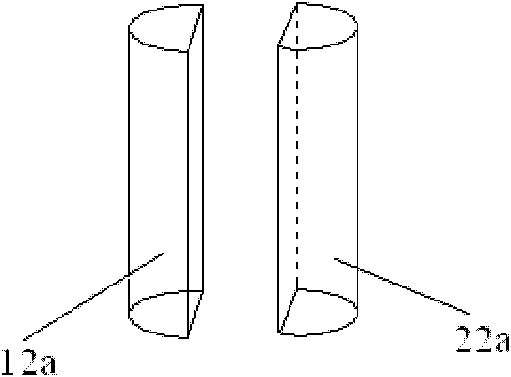

[0025] According to a typical embodiment of the present invention, the manufacturing method of the PDP discharge electrode includes the following steps: forming a first transparent electrode 11 and a second transparent electrode 21; forming a first transparent electrode 11 and a second transparent electrode 21 on the first transparent electrode 11 and the second transparent electrode 21 respectively. The bus electrode 12 and the second bus electrode 22; the first three-dimensional portion 12a and the second three-dimensional portion 22a are respectively formed on the first bus electrode 12 and the second bus electrode 22 by printing method, developing method or etching method. Wherein, the transparent electrodes and bus electrodes can be produced by conventional production methods in the art, such as printing method, developing method or etching method.

[0026] When the first three-dimensional part 12a and the second three-dimensional part 22a are produced by a printing method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com