Solid propellant and coating tensile bond strength test fixture

A technology of tensile bond strength and solid propellant, which is applied in the field of performance testing of propellants and explosives, can solve the problems of difficult coaxial alignment, large error in measurement results, and small degree of freedom of fixtures, etc., and achieves easy coaxial alignment, Guarantee the effect of accuracy and large activity space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

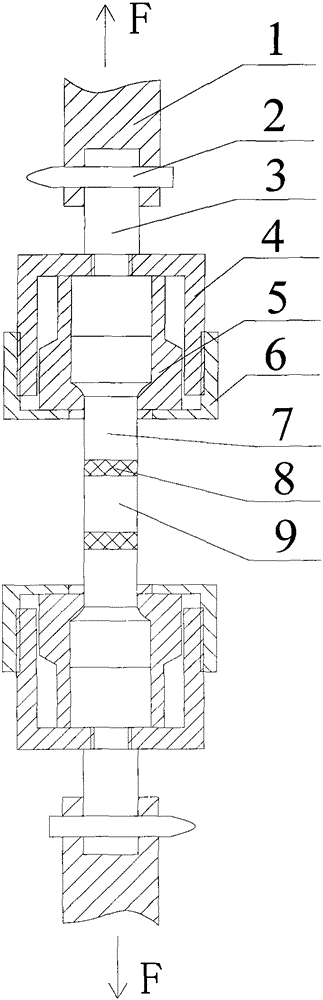

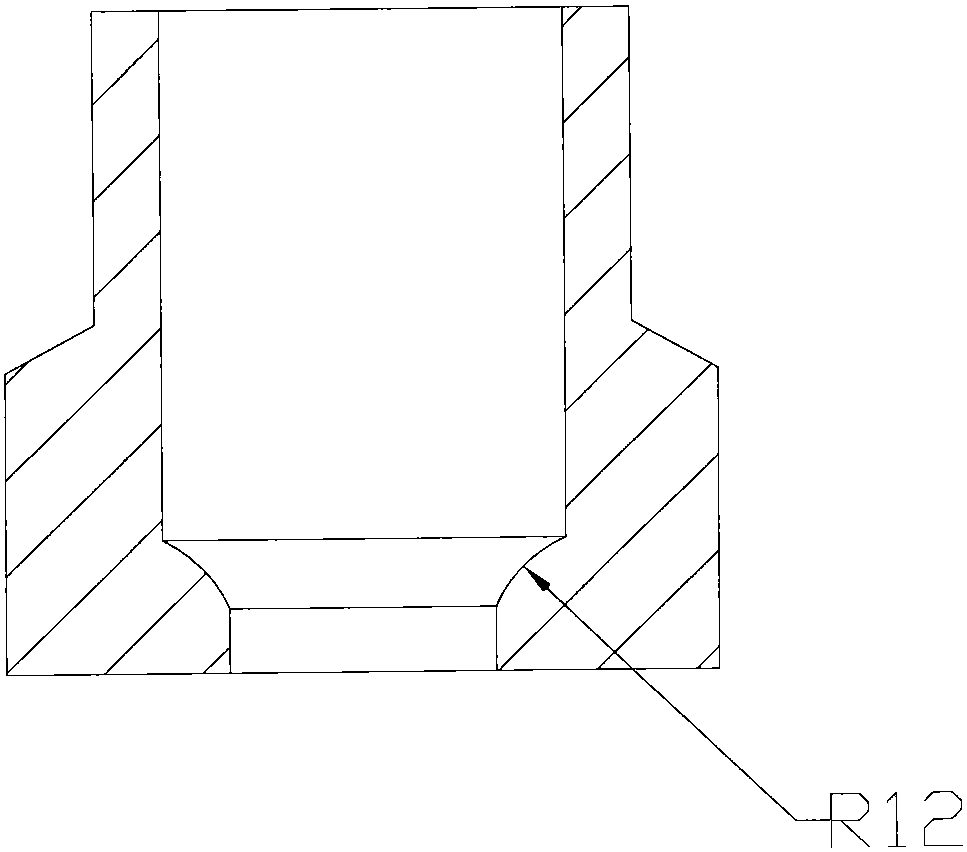

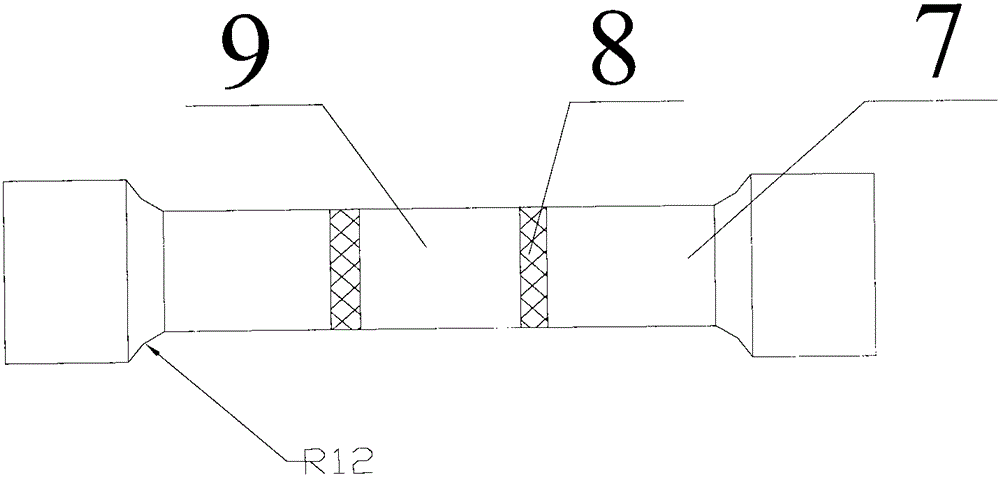

[0013] as figure 1 As shown, the test fixtures for the bond strength between the solid propellant and the cladding layer of the present invention are two sets of fixtures that are used symmetrically and have the same structure. Each set of fixtures includes a connecting rod 3, a fixed seat 4, a compression nut 6, two semicircular Wrist set 5, sample joint 7. All components except the sample joint 7 are made of stainless steel. The connecting rod 3 is cylindrical, one end has a radial through hole connected with the pull rod 1 of the tensile testing machine, and a section of threaded rod protrudes from the center of the other end face. The cylinder size of the connecting rod 3 is determined according to the diameter of the installation hole of the tensile testing machine pull rod 1. For the tensile testing machine pulling rod 1 of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com