Tempering prevention and abnormal combustion restraining method of hydrogen fuel combustion engine

A prevention method and abnormal combustion technology, applied in the direction of internal combustion piston engine, combustion engine, gaseous engine fuel, etc., to achieve the effect of taking into account both economy and power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

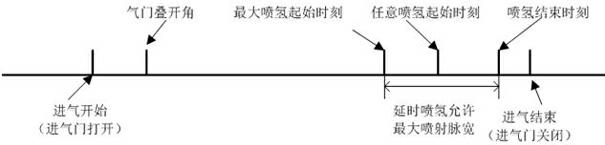

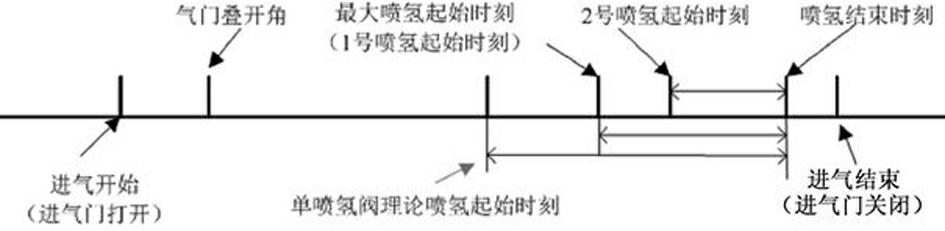

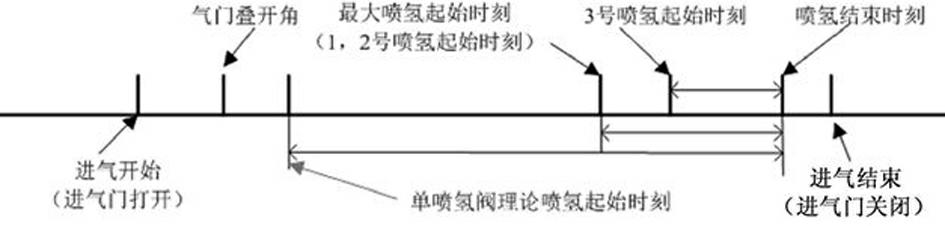

[0031] In general, the backfiring of a hydrogen engine is closely related to the timing, duration and ignition timing of hydrogen injection. When hydrogen injection enters the intake manifold, if it encounters a hot spot near the valve, or the exhaust gas enters the intake manifold when the valve overlaps, it may cause the mixture to burn in the intake pipe and cause backfire. In response to this situation, a multi-channel hydrogen injection system is used to prevent the occurrence of abnormal combustion by using a combination of parallel hydrogen injection of the multi-channel hydrogen injection system, delayed hydrogen injection of the intake pipe, fixed hydrogen injection end time and delayed ignition. In this embodiment, the hydrogen injection system is three-way, the hydrogen injection system is supplied with hydrogen in separate ways, and each hydrogen injection system uses a single solenoid valve. The specific measures taken are as follows:

[0032] 1) According to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com