Intelligent control method of engine cooling fan for engineering machinery

A technology of engine cooling and intelligent control, which is applied in the direction of engine cooling, coolant flow control, machine/engine, etc., to achieve high control accuracy and reliability, and prevent overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in combination with the principle diagram and specific operation embodiments.

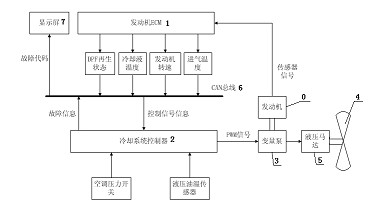

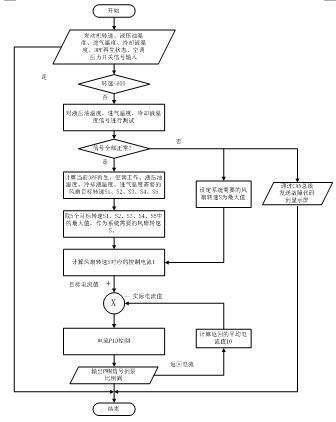

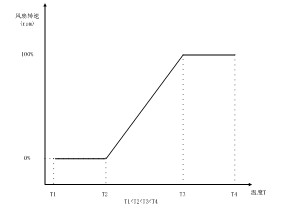

[0029] The intelligent control method of the engine cooling fan for construction machinery of the present invention is applied to the cooling system of the hydraulic drive fan mode, such as figure 1 As shown, the cooling system includes an engine electronic control module 1 and a cooling system controller 2. A hydraulically driven variable pump 3 is added to the power output port of the engine 0, and the hydraulically driven variable pump 3 supplies oil to the hydraulic motor 5 integrated with the cooling fan 4 , The rotation of the cooling fan 4 is driven by the rotation of the hydraulic motor 5 to cool the whole system. The cooling system controller 2 collects the hydraulic oil temperature signal and the air conditioner pressure switch signal, and receives the intake air temperature signal, the diesel particulate filter regeneration status ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com