Adhesive tape inclined shaft exploitation way for large-scale underground metal mine

A large-scale land and adhesive tape technology, which is applied in underground transportation, mining equipment, earth drilling and mining, etc., can solve problems such as application restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

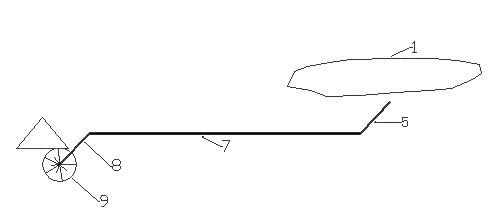

[0052] Embodiment 1, as Figure 5 , 6 7. Shown in 7: Dahongshan Iron Mine Underground 4000000 t / a Mining Phase 1 Project Tape Inclined Shaft Development System, the main Tape Inclined Shaft section is set on the flank of the main ore body, consisting of 4 sections (2 sections underground, 2 sections on the surface) Section), adopt the setting method of rail maintenance road in the same wellbore.

[0053] The project adopts the belt inclined shaft-trackless ramp-auxiliary blind shaft joint development method. The ore belt transportation system from the underground to the surface dressing plant is composed of 4 sections of belt, that is, the short belt conveyor section 5 protected by ore protection, and the two main sections. Belt inclined shaft sections 7-1 and 7-2 are composed of ore unloading point reloading conveyor section 8, which is set on the flank of main ore body 1. Mined ore is crushed by underground crushing station 2 and then sent to crushed ore bin 3. The ore fee...

Embodiment 2

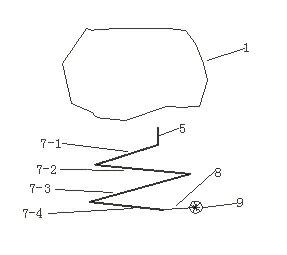

[0055] Embodiment 2, as Figure 8 , 9 10 and 10: The ore body mined in the second phase of the deep part of Dahongshan Iron Mine has a buried depth of about 700-1000m, and the development system adopts the joint development method of tape inclined shaft-trackless ramp-auxiliary shaft.

[0056] The main belt inclined shaft section is set in the middle of the flank of the main ore body 1, and consists of 7 sections (5 underground sections, 2 surface sections), the ore-protected transfer short belt conveyor section 5, and the five-section turn-back type main belt inclined shaft section 7-1, 7-2, 7-3, 7-4, 7-5, and unloading point transfer conveyor section 8, adopting the setting method of setting trackless maintenance road in the same shaft; the total lifting height reaches 783m, The total length is about 5000m, and the transportation capacity is further increased to 6 million t / a, 1250t / h.

[0057] in:

[0058] The inclined shaft section 7-1 of the main tape has an inclinati...

Embodiment 3

[0064] Embodiment 3, as Figure 11 , 12 , 13 shown. The first phase of the Dahongshan Copper Mine project has an ore body with a buried depth of more than 300m. It adopts the method of setting up railed auxiliary inclined shafts in parallel with the belt inclined shaft to form parallel double inclined shafts. The auxiliary inclined shaft is used as the inspection channel for the belt conveyor in the belt inclined shaft. . The transportation volume reaches 4 million t / a, 13000t / d.

[0065]

[0066] The main belt inclined shaft is set on the flank of the main ore body 1, and consists of 5 sections (2 sections underground, 3 sections on the surface), the section 5 is protected by the ore-protected transshipment short belt conveyor, the three-section turn-back type main belt inclined shaft section 7-1, 7-2, 7-3, and the ore unloading point reloading conveyor section 8 are formed, and the rail auxiliary inclined shaft shaft 12 is arranged in parallel with the tape inclined shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com