Preparation method for graphene-containing nanopaper

A technology of graphene and nano paper, which is applied in the field of material science, can solve the problems of low degree of graphitization, achieve the effects of improving wave absorption characteristics, increasing loss rate, and reducing surface reflection ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

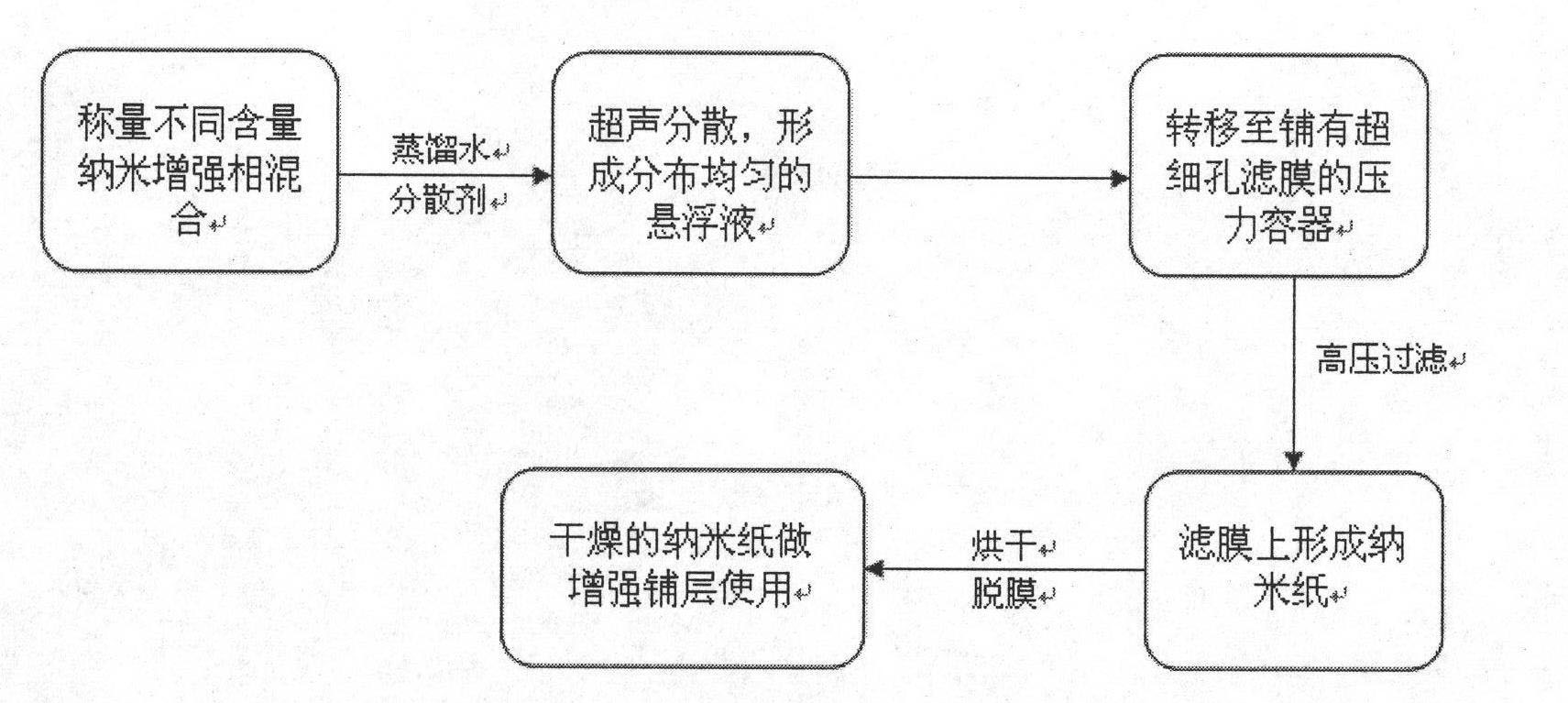

[0021] Example 1: Combining figure 1 , a method for preparing nano paper containing graphene in the present invention,

[0022] Proceed as follows:

[0023] Step 1: Weigh 30g of natural flake graphite with a particle size of ≤45μm as raw material, dry it in an oven at 80°C for 24 hours, and prepare 30ml of concentrated H 2 SO 4 , 10g K 2 S 2 o 8 , 10g P 2 o 5 After mixing evenly, place it in a flask, add 30g of dried graphite into the flask, and heat to 80°C for oxidation reaction;

[0024] Step 2: oxidizing the natural flake graphite treated in step 1 by the Humers method to obtain graphite oxide;

[0025] Step 3: Add the graphite oxide obtained in Step 2 into the mixed solution of N, N-dimethylformamide and water, then treat it at 100W ultrasonic power for 3h, centrifuge at a speed of 4000r.p.m. for 40min, and transfer Remove the centrifuged precipitate to obtain a graphene oxide dispersion;

[0026] Step 4: After the graphene oxide dispersion obtained in step 3 is...

Embodiment 2

[0031] Example 2: Combining figure 2 , the preparation of reduced graphene oxide:

[0032] Weigh 30 g of natural flake graphite with a particle size of ≤45 μm as a raw material, and dry it in an oven at 80° C. for 24 hours before use. 30mL H 2 SO 4 , 10gK 2 S 2 o 8 , 10gP 2 o 5 The mixture is placed in a flask, and 30g of the above-mentioned dried natural graphite is added. Heat to 80°C, stop heating when the reactant completely turns blue-black, cool to room temperature and let stand for 6h. Rinse thoroughly with water and filter the reactant until the filtrate is neutral. Drying at room temperature, the product after drying in the previous step was mixed with concentrated H 2 SO 4 Slowly add KMnO in a water bath at 0°C 4 , control the temperature and slowly add distilled water to the flask to maintain the reaction for a period of time. Finally, add distilled water and H 2 o 2, the mixture turned from tan to bright yellow. Wash and filter the above reaction p...

Embodiment 3

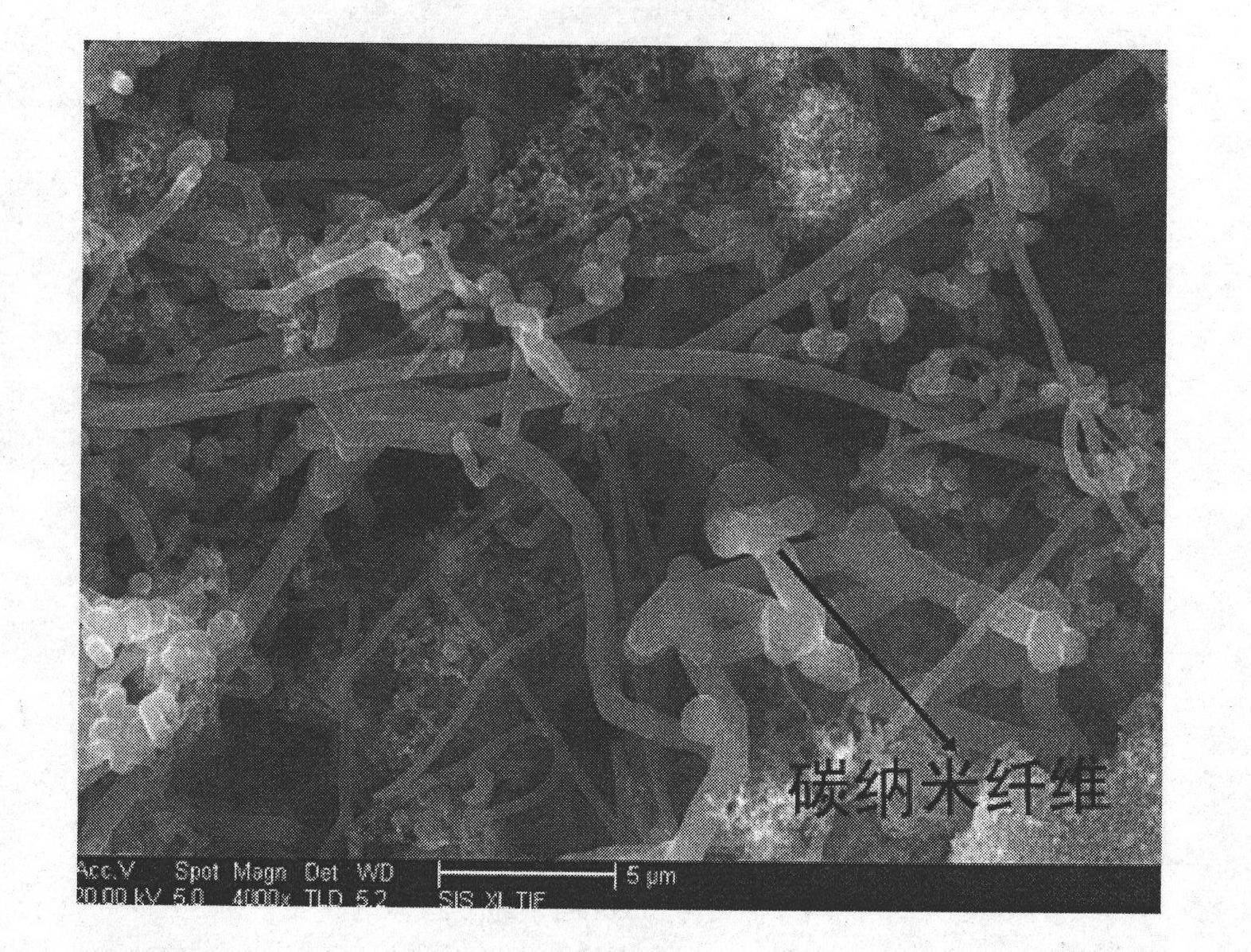

[0033] Embodiment 3: the preparation that contains graphene nano paper:

[0034] Weigh 1.8g of carbon nanofibers, add deionized water, and the mass ratio of deionized water to carbon nanofibers is 100:1 to obtain a suspension. The suspension is mechanically stirred for 15 minutes, and then mixed under the condition of an ultrasonic frequency of 30Hz. Ultrasonic dispersion of the liquid for 40 minutes to form a uniformly distributed suspension, then arrange the pressure vessel, lay the ultra-fine filter membrane flat on the filter sieve, add a small amount of water to moisten, seal the pressure vessel, and put the suspension after ultrasonic treatment Transfer to a pressure vessel, and pressurize the suspension in the solution through an air compressor. When there is no large amount of water in the vessel, take out the wet filter membrane and the nano-paper on it, and carefully transfer it to a drying box. The drying temperature is From 100°C to 1300°C, the initial heating rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com