Corner connecting assembly for deckhead

A corner connection and ceiling technology, applied in the direction of the living cabin, etc., can solve the problems of falling off decorative strips, increasing the workload of installation, safety accidents, etc., and achieve the effect of avoiding the chamfering process, reducing dangerous accidents, and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

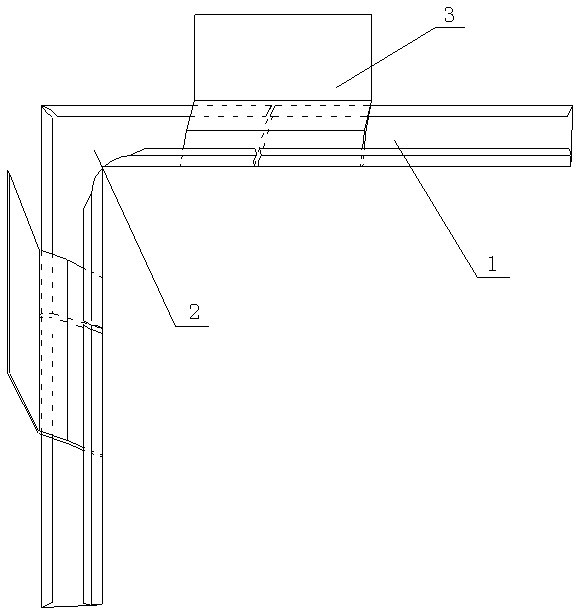

[0024] See Figure 1 to Figure 6 , The corner connecting assembly for the cabin ceiling of the present invention includes a decorative strip 1, a decorative strip corner piece 2 and a connecting piece 3.

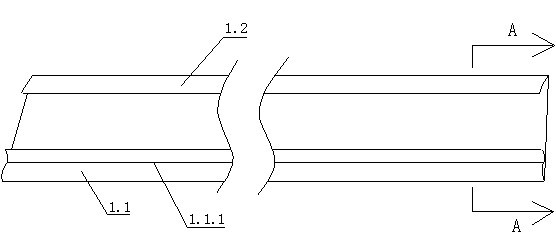

[0025] The decorative strip 1 is made of steel and has a long strip structure. The inner and outer sides of the decorative strip 1 are turned toward the inner side of the decorative strip 1 to form an inner flange I1.1 and an outer flange I1.2. There is a groove I1.1.1 at the top of the inner flange I1.1. The back of the groove I1.1.1 is close to the front surface of the decorative strip 1, and the outer flange I1.2 is arranged diagonally upward, making the outer flange The ends of I1.2 are upturned.

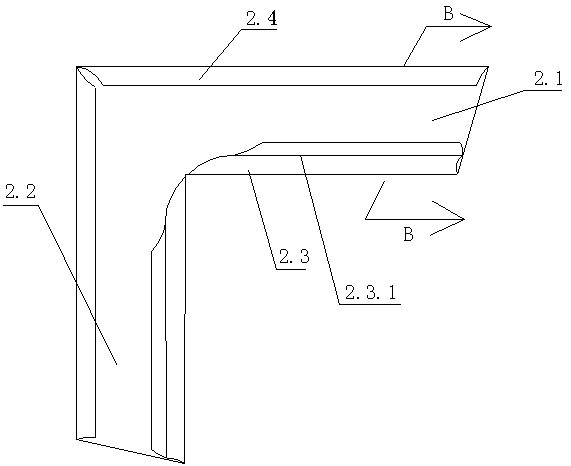

[0026] The corner piece 2 of the decorative strip is made of steel and has an "L" shape. It is composed of a horizontal section 2.1 and a vertical section 2.2. One end of the horizontal section 2.1 is close to one end of the horizontal decorative strip 1. One end of the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com