Beam current transmission system and method

A technology of current transmission and beam current, which is applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problems of low beam current intensity and long beam transmission path, so as to improve the beam current intensity, improve the uniformity of injection dose and inject Angle uniformity, the effect of improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

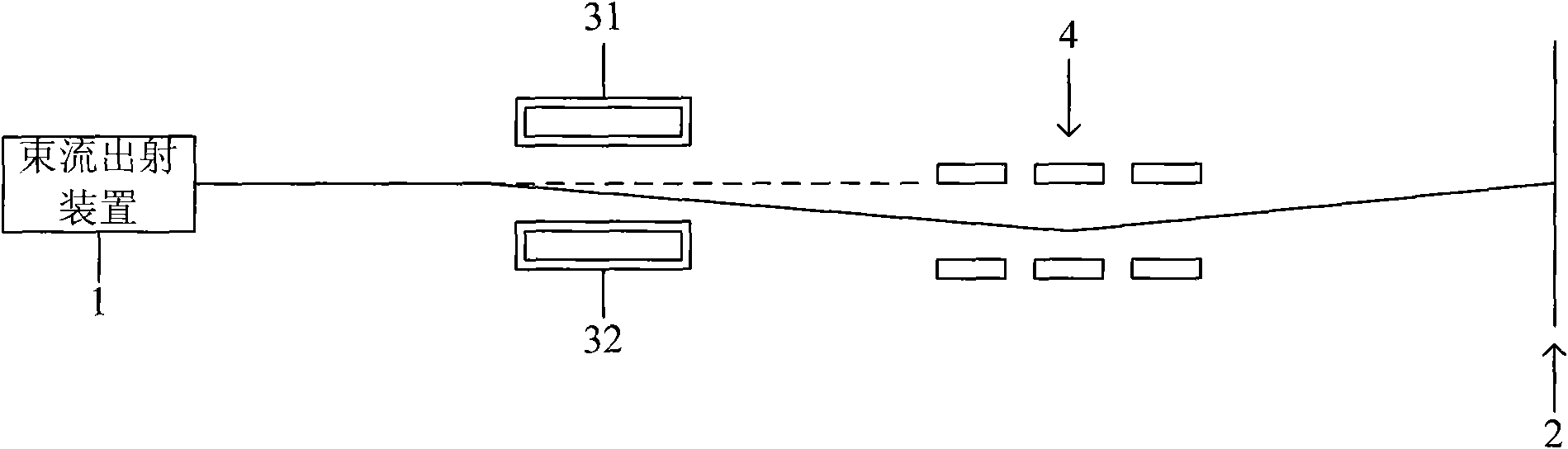

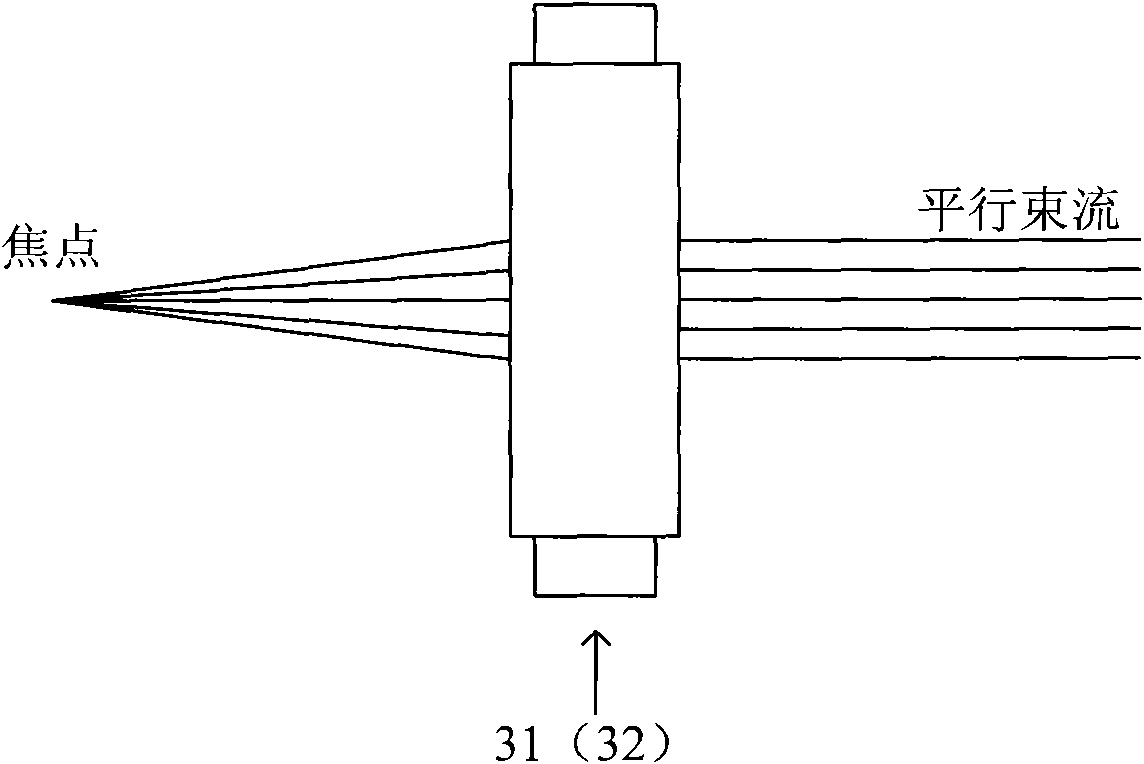

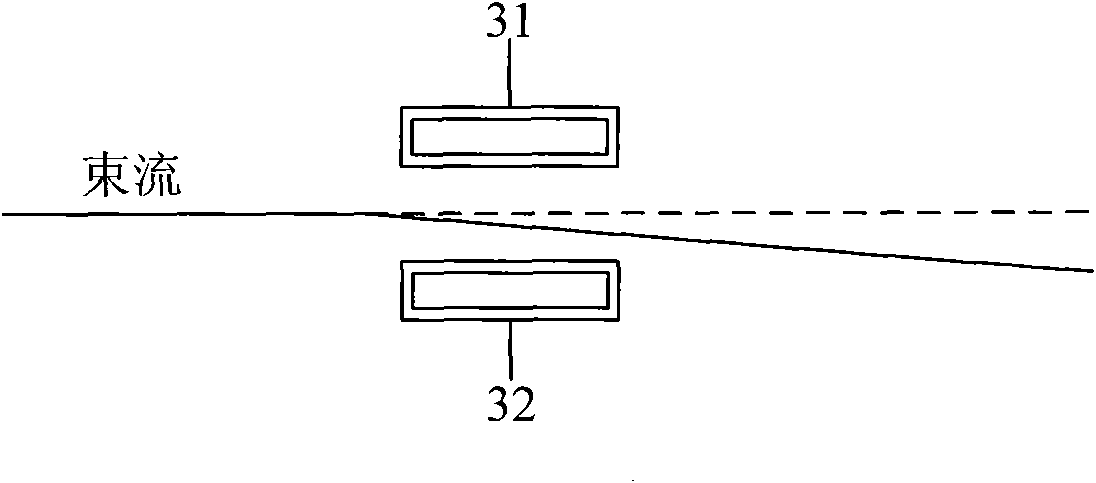

[0019] refer to figure 1 As shown, the beam transmission system of the present invention firstly includes a beam output device 1 as the starting point of the beam transmission and a target workpiece 2 as the end point of the beam transmission. The beam exit device 1 is used to generate an ion beam or an electron beam. During the transmission of the beam, its transmission state will be controlled by various beam optical elements arranged on the beam transmission path, so that when the beam When the flow finally reaches the target workpiece 2, various state parameters such as its intensity distribution and angular distribution can meet the preset requirements of the process, so as to achieve better injection dose uniformity and Injection angle uniformity.

[0020] In particular, in the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com