Multifunctional process control experiment platform

A process control and experimental platform technology, applied in non-electric variable control, control/regulation systems, and simultaneous control of multiple variables.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Decoupling control, the method is as follows:

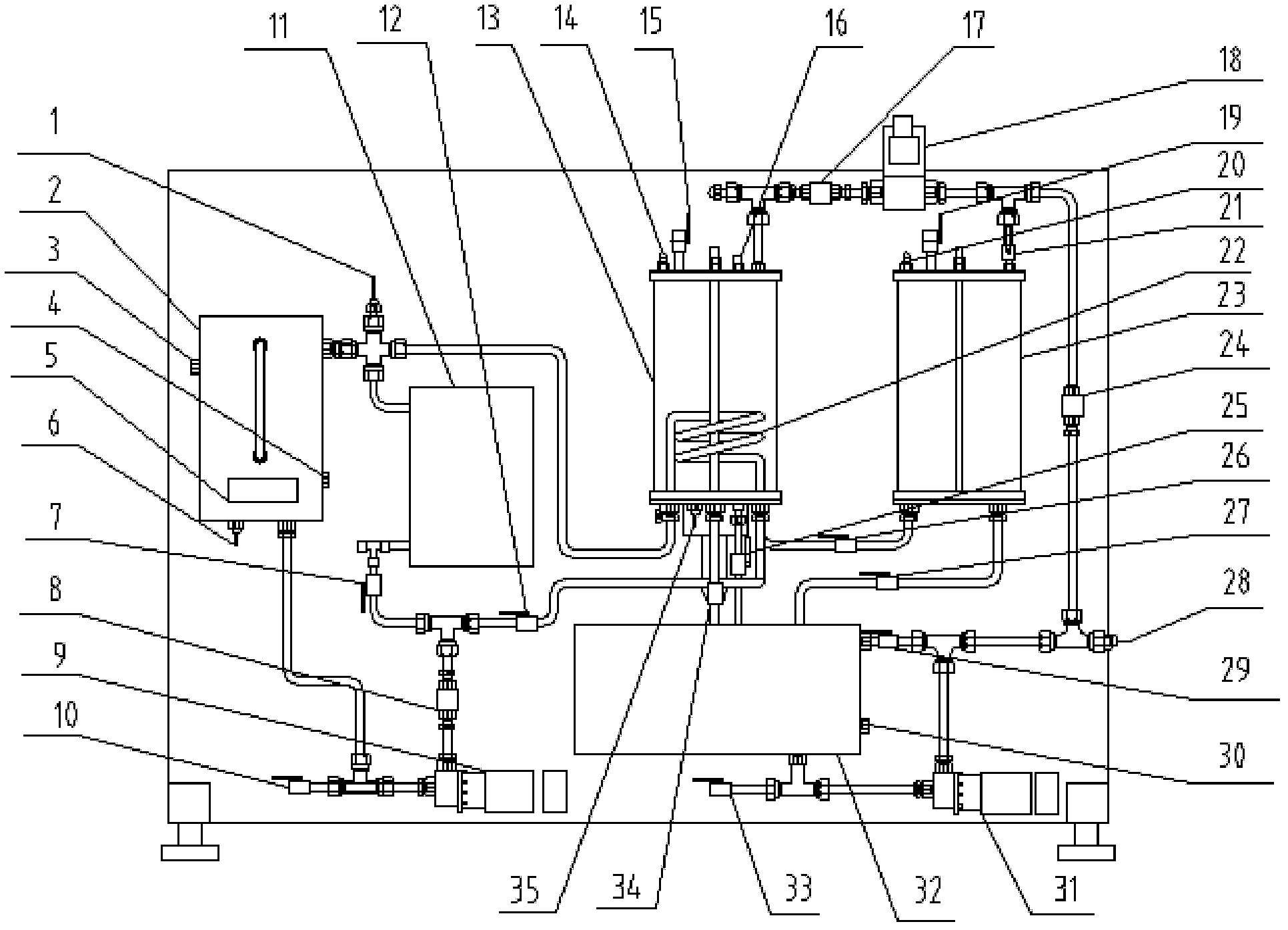

[0058] The dual-capacity water tank liquid level control system in the normal temperature water flow circuit not only has state coupling, but also has input coupling. This embodiment takes the dual-capacity water tank liquid level system as an example to illustrate that this platform has good decoupling capabilities.

[0059] Figure 8 It can be seen that when the connecting valve between the double-capacity water tanks is opened, the liquid levels of No. 1 water tank and No. 2 water tank will interact with each other through the pressure difference, thus having a liquid level coupling relationship; because in the liquid level system of the double-capacity water tanks, the water always enters The flow comes from the water pumped by the No. 2 water pump from the water storage tank, so adjusting the proportional valve will not only directly affect the water flow of the No. 1 water tank, but also indirectly affect the water f...

Embodiment 2

[0071] Single-capacity water tank temperature control, the method is as follows:

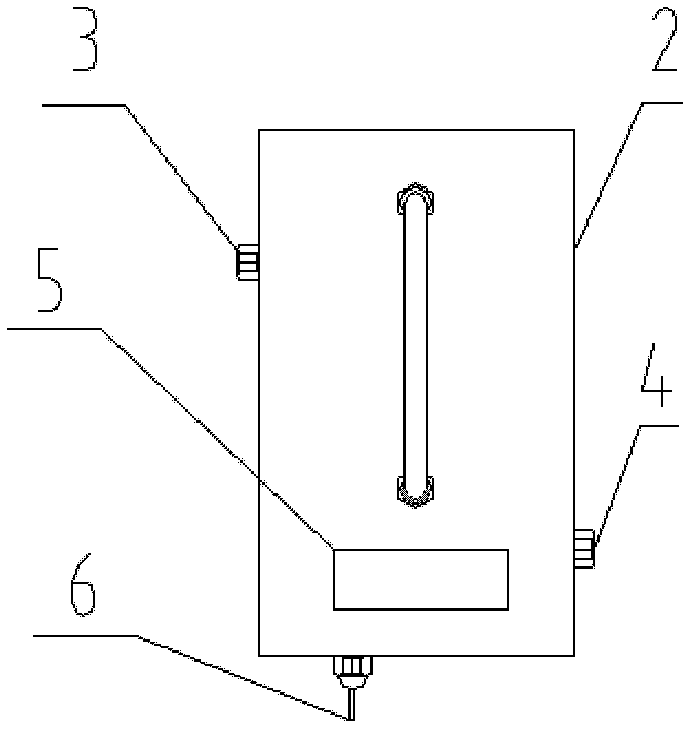

[0072] The single-capacity water tank temperature control system is composed of a heating water tank 2 and a No. 1 temperature sensor 6. The No. 1 temperature sensor measures the temperature in the heating water tank; the PI controller parameter corresponding to the No. 1 temperature sensor is k p =0.3378,k i =5.347×10 -5 , the set value of the water temperature is 50°C, the temperature control curve of the heating water tank is as follows Figure 13 shown. It can be seen from the figure that the temperature in the heating water tank can reach and stabilize at a given temperature in a short period of time, and the overshoot is extremely small, which has a good control effect. It also shows that the system structure can realize the temperature control of a single-capacity water tank experiment.

Embodiment 3

[0074] Heat exchange circuit temperature control, the method is as follows:

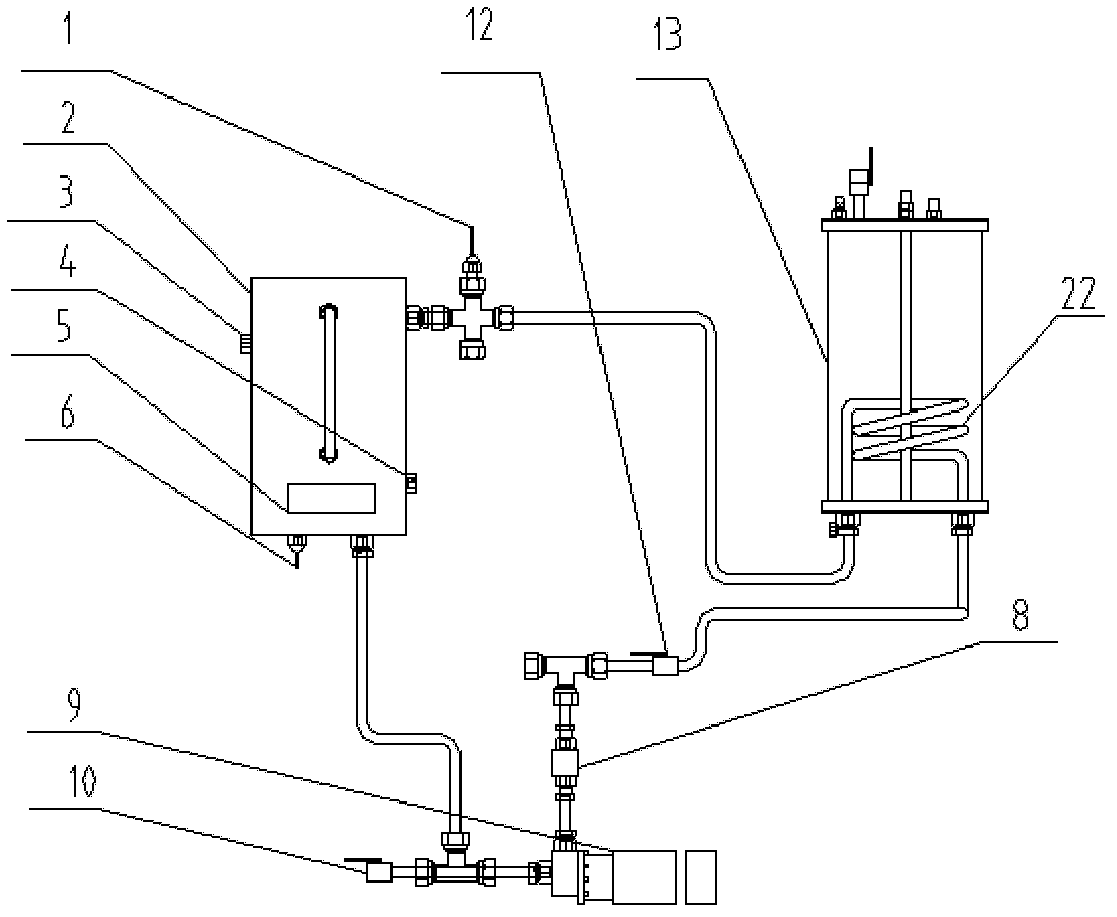

[0075] The heat exchange circuit is composed of No. 1 water pump 9, heating water tank 2, heat exchanger 22, No. 1 water tank 13 and No. 3 temperature sensor 35. Among them, No. 3 temperature sensor is used to measure the temperature of the water in the No. 1 water tank, and the 1 The liquid level in the No. water tank is kept at 10cm, and the PWM duty cycle of the first water pump is set to 60%. At the same time, the PI controller corresponding to the No. 1 temperature sensor is used to keep the temperature in the heating water tank at 45°C, so that the heat in the heat exchanger The temperature response curve in the No. 1 water tank detected by the No. 3 temperature sensor is shown in Figure 14; it can be seen from the figure that the temperature in the No. 1 water tank can reach and stabilize at 43.5°C through heat exchange, indicating that the loop structure can Realize the heat exchange experime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com