Light sensitization composition using p-toluenesulfonylhydrazide hydrazone compound and application of light sensitization composition

A technology of using sulfonyl hydrazide hydrazone and composition, applied in the application field of positive thermal CTP plates, can solve the problems of poor thermal stability and short storage life, and achieve good thermal stability, long service life, Fast developing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of Positive Thermal CTP Plate

[0027] (1) Preparation of aluminum plate base:

[0028] An aluminum plate with a thickness of 0.28mm is subjected to degreasing treatment for 40 seconds in a 7wt% sodium hydroxide aqueous solution at a temperature of 55°C. Use sine wave alternating current for electrolytic treatment, 50HZ alternating current, current 50A / dm 2 , the electrolysis time is 60 seconds, control Ra=0.3-0.6um, preferably 0.4-0.6um, .Rz (H) The value is 2~3μm. Then, at a temperature of 60°C, deslagging treatment was performed for 10 seconds in a 50wt% aqueous solution of sodium hydroxide, and then at a temperature of 25°C, the current density was 5A / d m 2 , the concentration is 20wt% sulfuric acid solution for 40 seconds, control oxide film = 2.5-3.5g / m 2 . Finally, at 60 °C with NaH 2 PO 4 -NaF solution is sealed for 30 seconds to obtain an aluminum base suitable for a lithographic printing plate.

[0029] (2) Apply the prepared photosensitive...

Embodiment 2

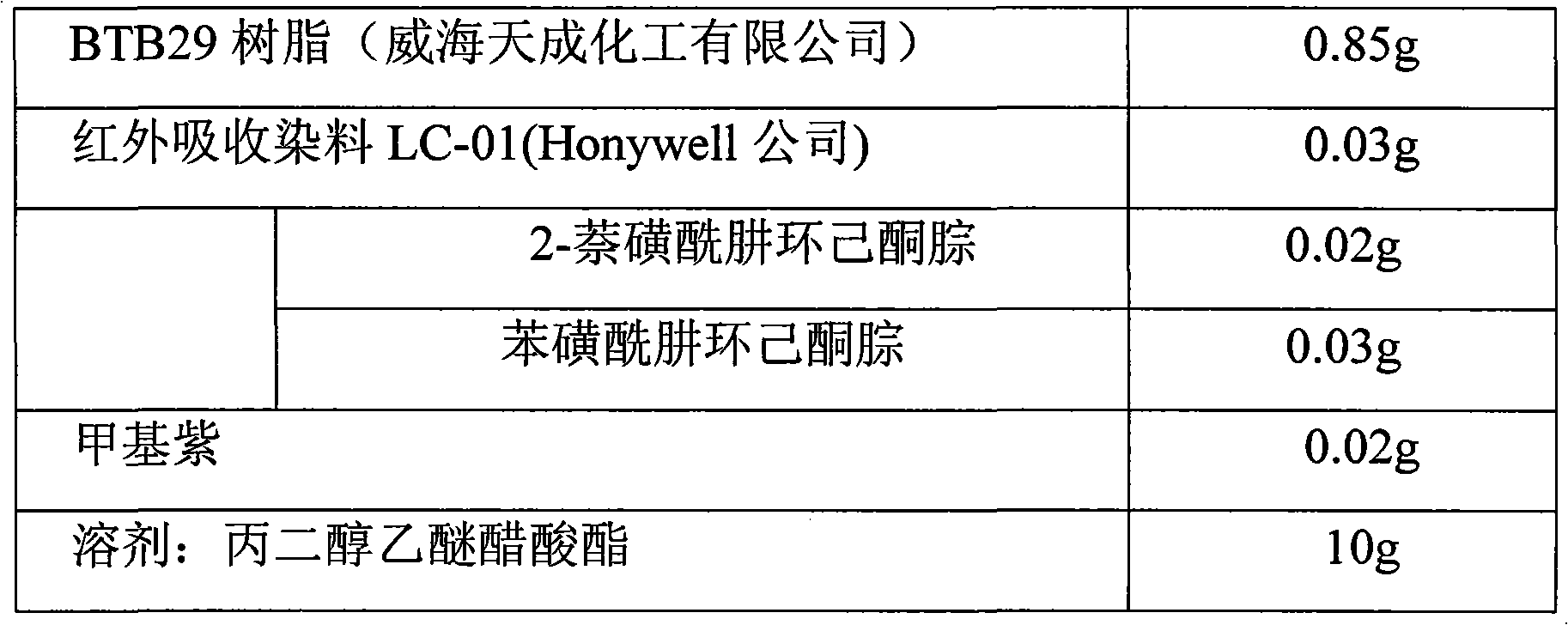

[0050] The photosensitive liquid is shown in Table 4:

[0051] Table four

[0052] BTB29 resin (Weihai Tiancheng Chemical Co., Ltd.) 0.85g Infrared absorbing dye LC-01 (Honywell company) 0.03g p-toluenesulfonyl hydrazide cyclohexanone hydrazone 0.05g

[0053] methyl violet 0.02g Solvent: Propylene Glycol Ether Acetate 10g

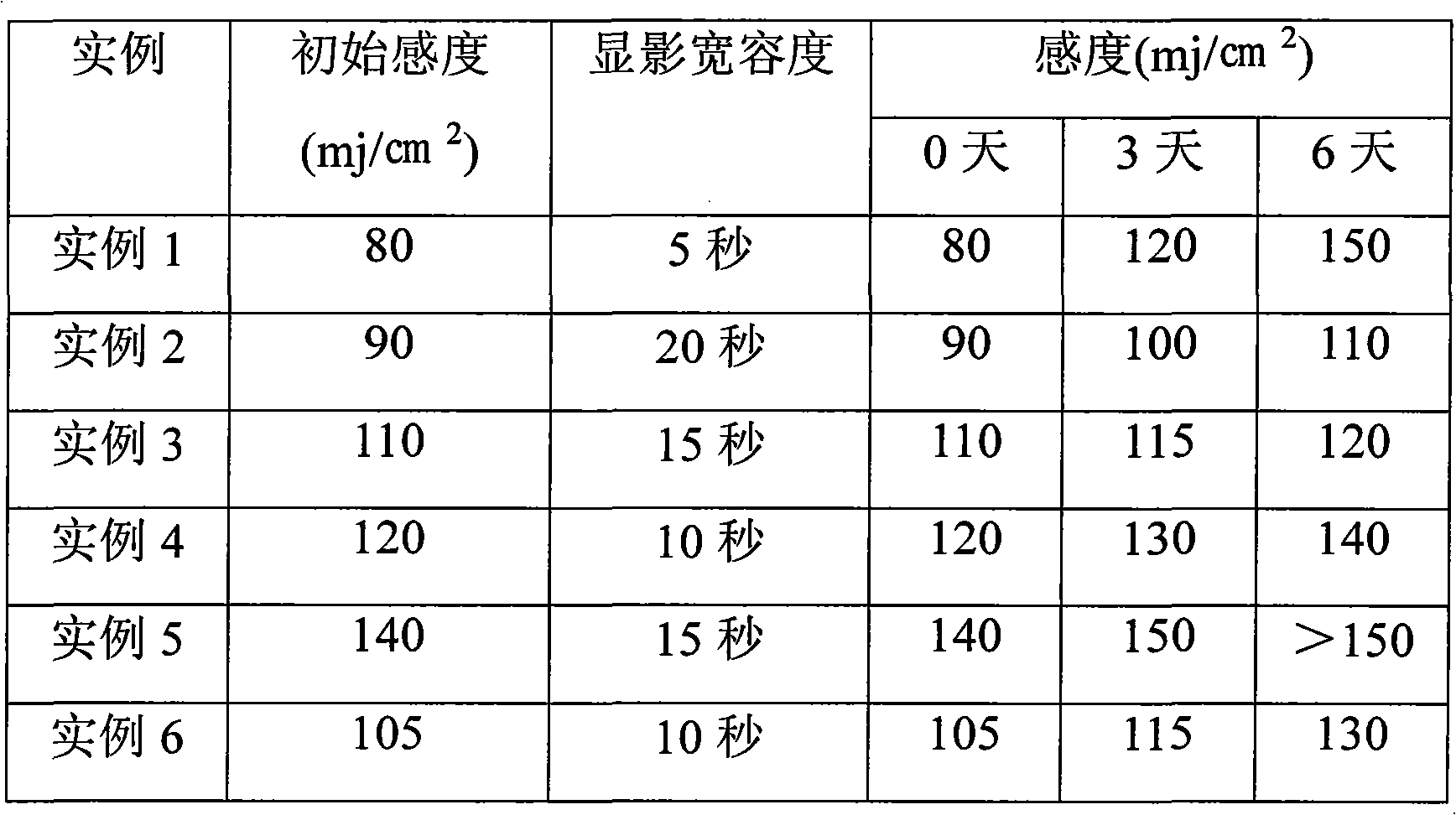

[0054] The above-mentioned photosensitive lithographic plate is installed on the plate-making machine for exposure. Use alkaline developer TPD-II (manufactured by Lucky Group No. 2 Film) to develop at 25°C for 30 seconds. The results of sensitivity, development latitude and photosensitive solution stability are shown in Table 9.

Embodiment 3

[0056] The photosensitive liquid is shown in Table 5:

[0057] Table five

[0058] BTB29 resin (Weihai Tiancheng Chemical Co., Ltd.) 0.85g Infrared absorbing dye LC-01 (Honywell company) 0.03g p-tert-Butylbenzenesulfonyl hydrazide cyclohexanone hydrazone 0.05g methyl violet 0.02g Solvent: Propylene Glycol Ether Acetate 10g

[0059] The above-mentioned photosensitive lithographic plate is installed on the plate-making machine for exposure. Use alkaline developer TPD-II (manufactured by Lucky Group No. 2 Film) to develop at 25°C for 30 seconds. The results of sensitivity, development latitude and photosensitive solution stability are shown in Table 9.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com