Composition of black and white electrophoretic display liquid for electrophoretic display and preparation method thereof

An electrophoretic display, black and white technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of slow response speed, less research on dispersion media, poor response contrast, etc., to improve response speed, improve display effect, reduce The effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

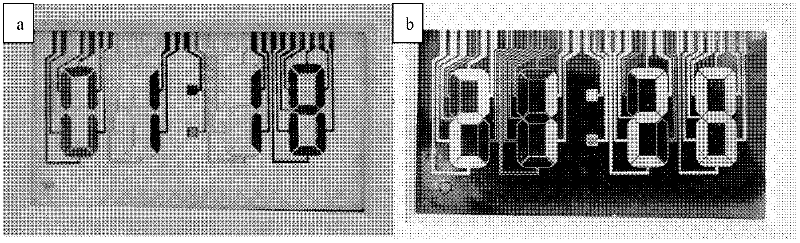

Image

Examples

example 1

[0029] In the ball mill bottle, add 10mL of Isopar G, 0.05g of T31, 0.10g of CH-5 and 1.00g of TiO 2 Nanoparticles or 0.30g carbon black nanoparticles were ground with 2mm zirconia zirconia beads as the grinding medium at a speed of 600r / min for 20h to prepare white and black electrophoretic display solutions, respectively. Mix the black and white electrophoretic display solution at a ratio of 1:30, add 0.02g of perfluorooctanesulfonyl fluoride and 0.03g of A4100, and mix evenly to obtain the black and white particle electrophoretic display solution.

[0030] Put the electrophoretic display solution of the present invention into the sedimentation bottle, and observe that the display solution remains stable after standing for a week. Fill the electrophoretic display solution of the present invention into the microcup display device, the distance between the two pole plates is 0.1mm, apply a positive and negative alternating voltage of 15V, and observe the display effect, the co...

example 2

[0032] In the ball mill bottle, add 10mL of Isopar H, 0.20g of T152, 0.50g of CH-6 and 5.00g of TiO 2 Nanoparticles or 2.00 g of carbon black nanoparticles were ground with 2 mm zirconia zirconia beads as the grinding medium at a speed of 600 r / min for 24 hours to prepare white and black electrophoretic display solutions, respectively. Mix the black and white electrophoretic display liquid at a ratio of 1:15, add 0.06 g of perfluorooctanesulfonyl fluoride and 0.20 g of A4100, and mix evenly to obtain the black and white particle electrophoretic display liquid.

[0033] Put the electrophoretic display solution of the present invention into the sedimentation bottle, and observe that the display solution remains stable after standing for a week. Fill the electrophoretic display solution of the present invention into the microcup display device, the distance between the two pole plates is 0.1mm, apply a positive and negative alternating voltage of 15V, and observe the display effe...

example 3

[0035] In the ball mill bottle, add 10mL of Isopar L, 0.10g of T151, 0.15g of CH-13 and 2.00g of TiO 2 Nanoparticles or 0.40 g of carbon black nanoparticles were ground with 2 mm zirconia zirconia beads as the grinding medium at a speed of 600 r / min for 28 hours to prepare white and black electrophoretic display solutions, respectively. Mix the black and white electrophoretic display solution at a ratio of 1:20, add 0.03g of perfluorooctanesulfonyl fluoride and 0.05g of A4100, and mix evenly to obtain the black and white particle electrophoretic display solution.

[0036] Put the electrophoretic display solution of the present invention into the sedimentation bottle, and observe that the display solution remains stable after standing for a week. Fill the electrophoretic display solution of the present invention into the microcup display device, the distance between the two pole plates is 0.1mm, apply a positive and negative alternating voltage of 15V, and observe the display e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com