Performance testing device for piston shoe in axial plunger pump

A technology of axial piston pump and testing device, which is applied in the field of hydraulic components, can solve problems such as the isolation of sliding shoe pairs and errors in test results, and achieve the effects of avoiding interference, less control components, and easy replacement of sliding shoes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

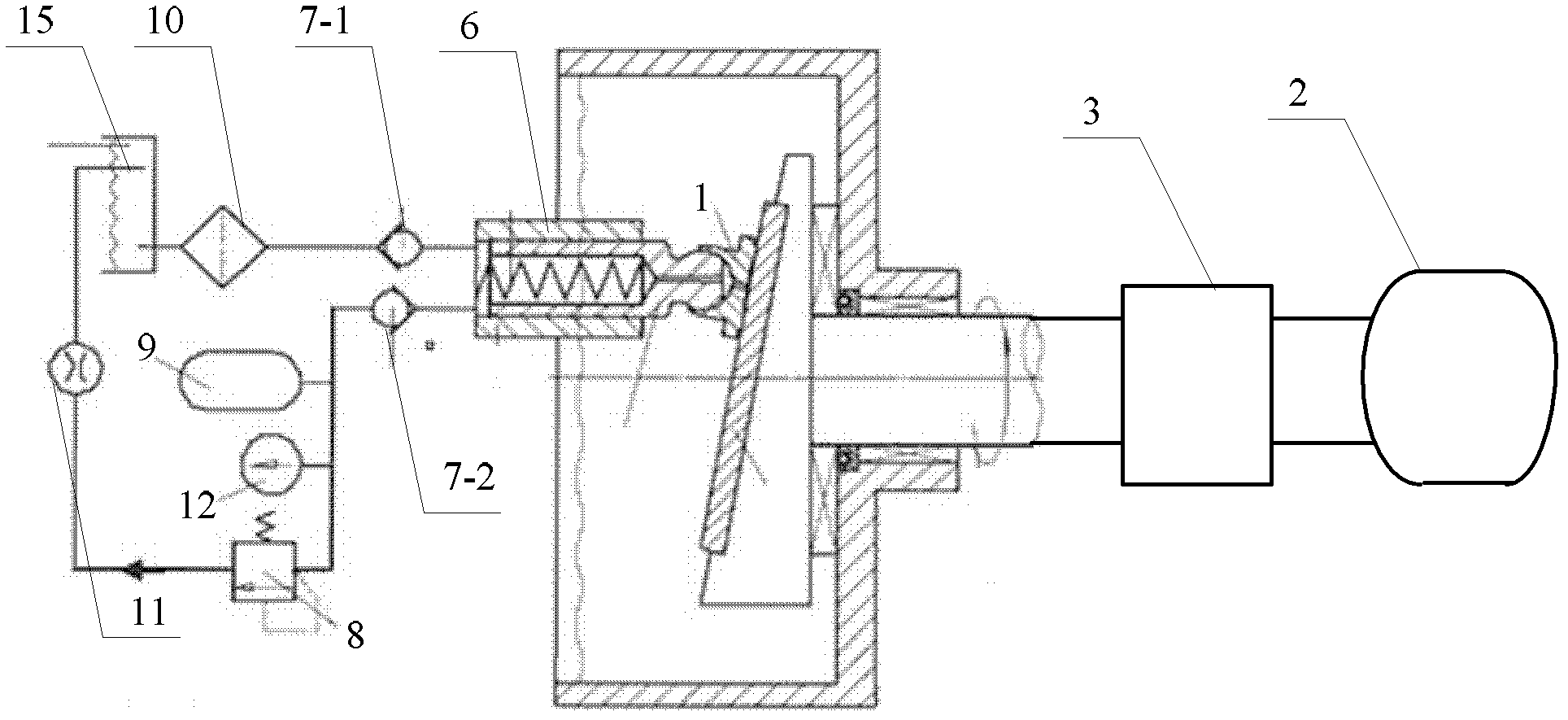

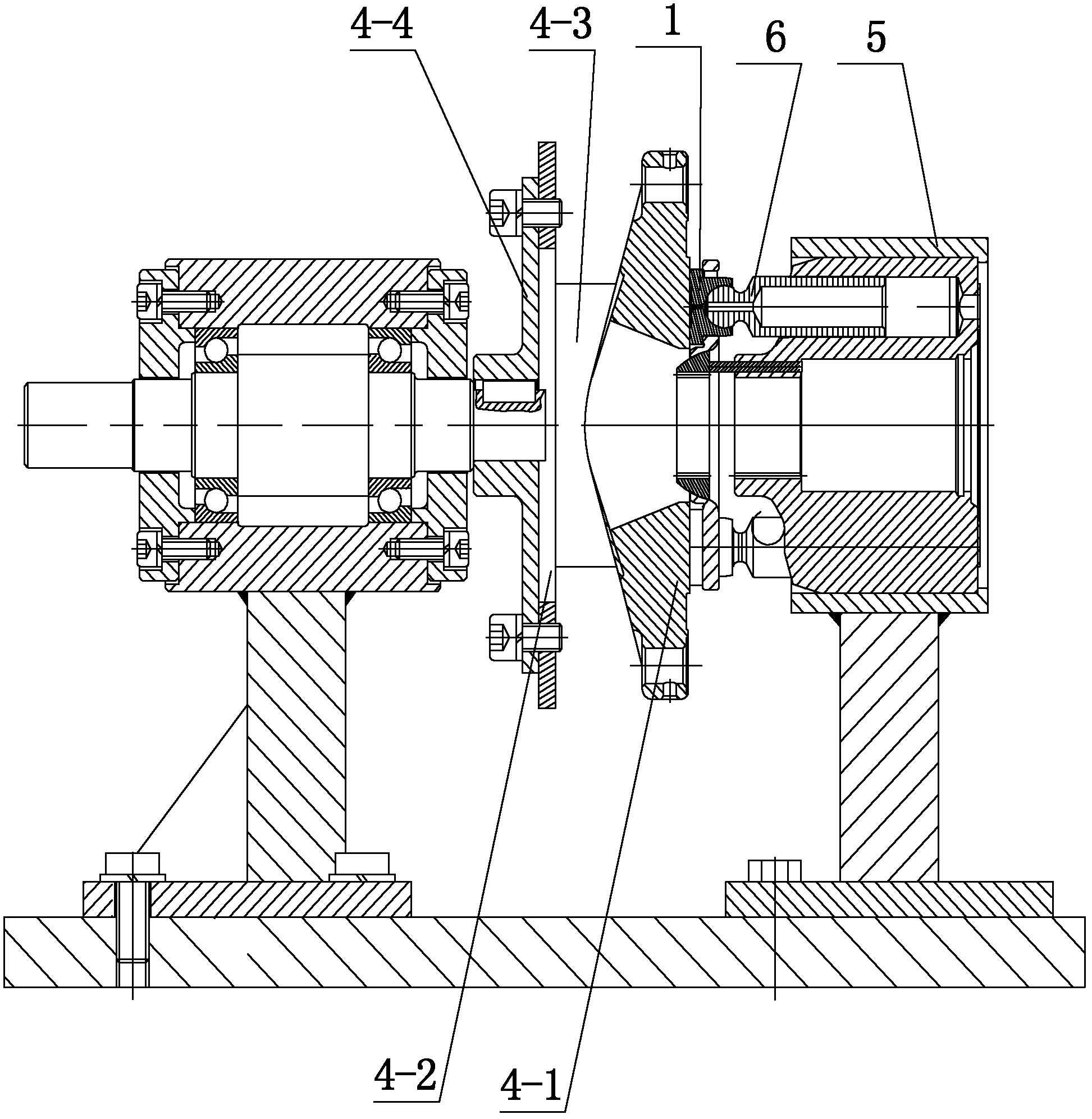

[0030] Specific implementation mode one: the following combination Figure 1 to Figure 10 Describe this embodiment, the test device for the performance of the sliding shoe in the axial piston pump described in this embodiment, it includes a sliding shoe 1, characterized in that: it also includes a frequency conversion motor 2, a speed torque sensor 3, a variable device, a hydraulic cylinder Body 5, plunger 6, flow meter 11, pressure gauge 12, oil tank 15 and temperature sensor 16,

[0031] The variable device is composed of a swash plate 4-1, a swash plate support tile 4-2, two fastening splints 4-3 and a shaft joint plate 4-4,

[0032] The shaft connecting plate 4-4 and the bottom plate of the swash plate support tile 4-2 are fixedly connected by bolts, the swash plate 4-1 is supported by the swash plate support tile 4-2, and the clamping plate 4-3 is provided with three threaded holes and a Waist-shaped groove, two fastening splints 4-3 are respectively arranged on both sid...

specific Embodiment approach 2

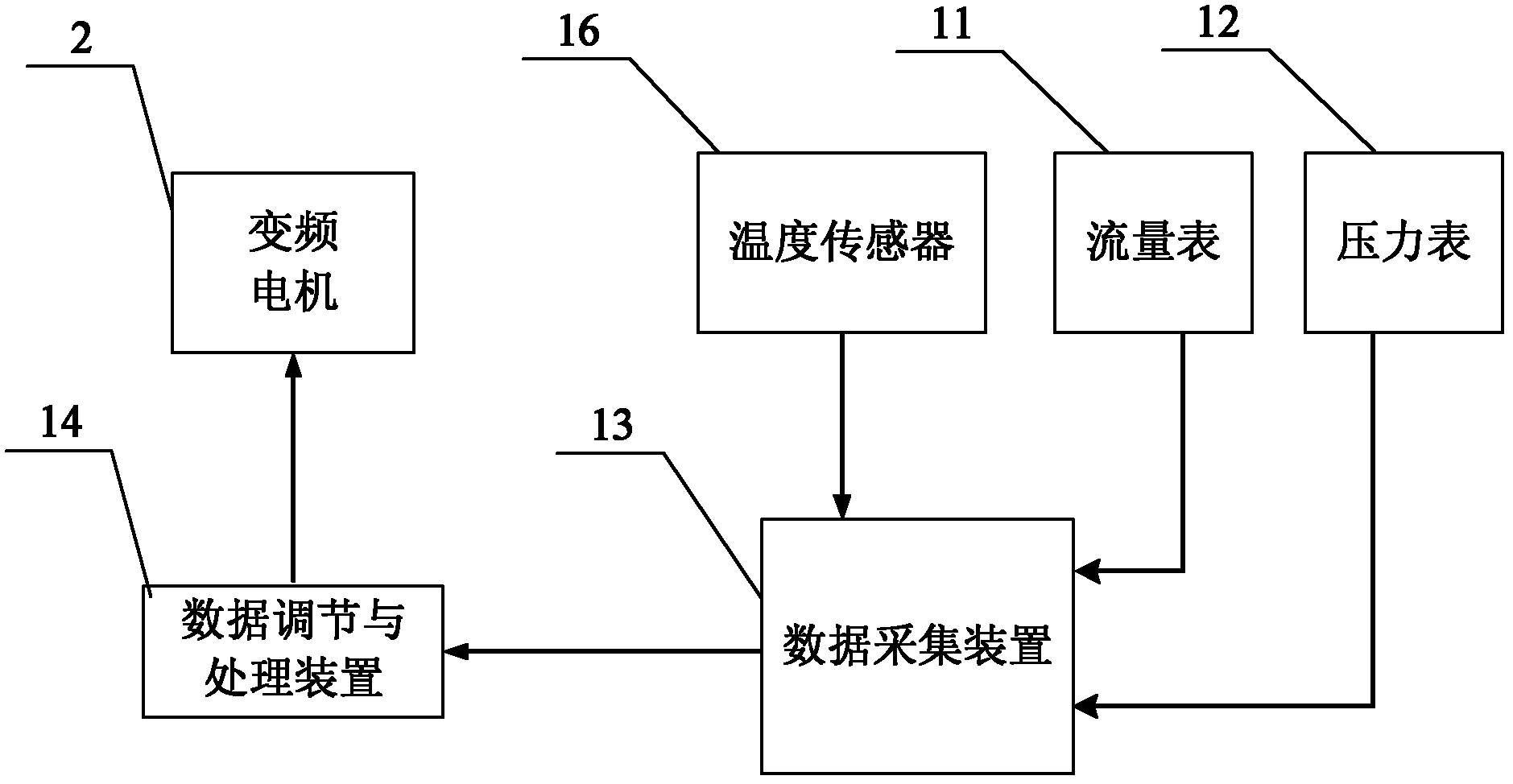

[0044] Specific implementation mode two: the following combination figure 2 Describe this embodiment, this embodiment is a further description of Embodiment 1, this embodiment also includes a data acquisition device 13 and a data adjustment and processing device 14,

[0045] The temperature data output end of the temperature sensor 16 is connected to the temperature data input end of the data acquisition device 13, the flow data output end of the flow meter 11 is connected to the flow data input end of the data acquisition device 13, and the pressure data output end of the pressure gauge 12 is connected to the data acquisition device The pressure data input end of 13, the data output end of data acquisition device 13 is connected with the data input end of data adjustment and processing device 14,

[0046] The motor control signal output end of the data adjustment and processing device 14 is connected to the control signal input end of the variable frequency motor 2 .

[004...

specific Embodiment approach 3

[0049] Specific implementation mode three: the following combination figure 1 Describe this embodiment, this embodiment is a further description of Embodiment 1 or 2, this embodiment also includes a first check valve 7-1, between the oil inlet of hydraulic cylinder block 5 and the oil outlet of oil tank 15 A first one-way valve 7-1 is arranged on the communication pipeline of the.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com