Apparatus for transporting fuel oil

A conveying device, fuel oil technology, applied in the direction of liquid distribution, conveying or transfer device, distribution device, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

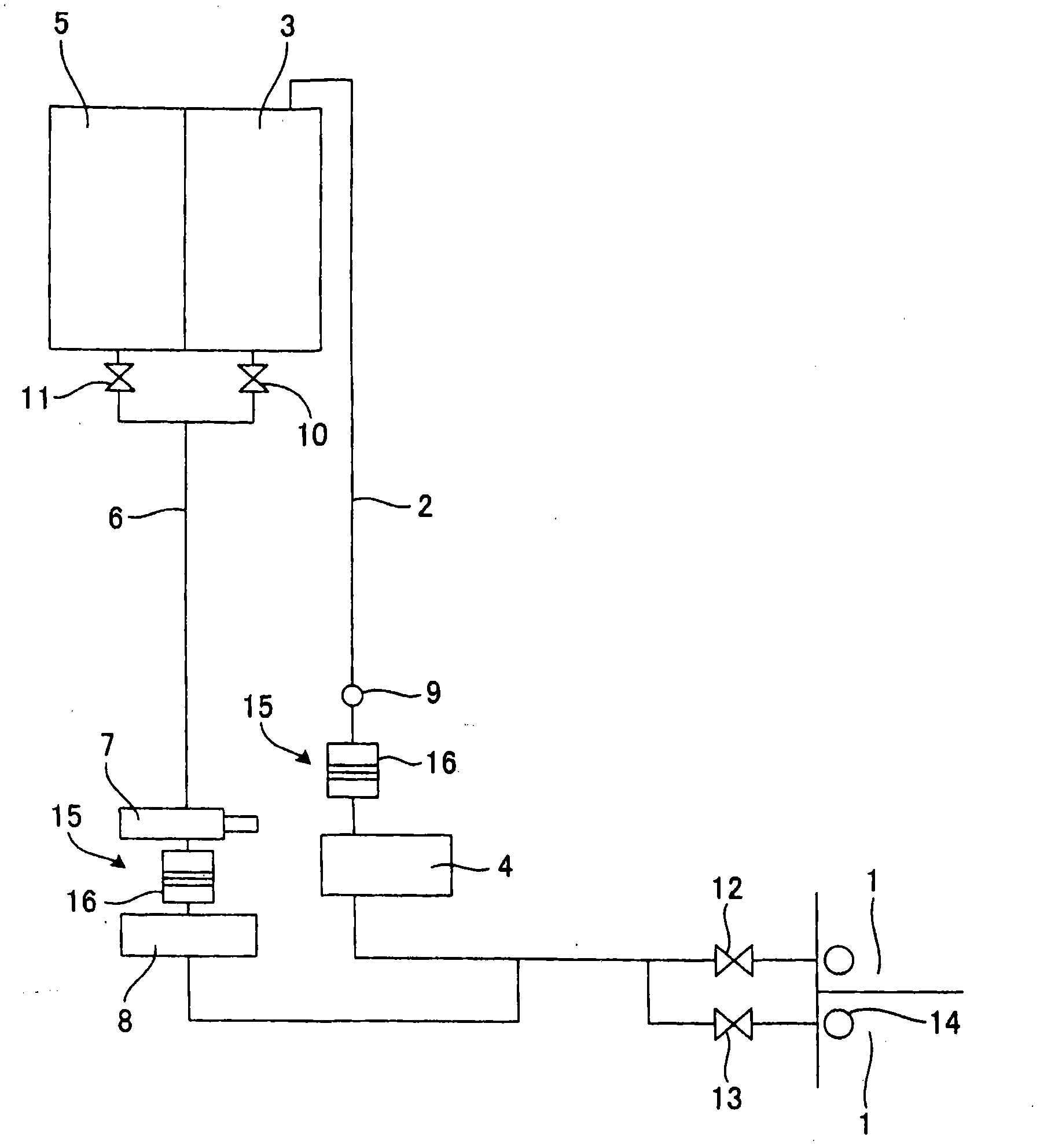

[0017] exist figure 1 Among them, the fuel delivery device of the present invention has: a fuel storage cabinet 1, which has a main suction pipe 14; a fuel oil settling cabinet 3, which communicates with the fuel storage cabinet 1 via a delivery pipeline 2; a delivery pump 4, which is arranged in the delivery pipeline 2, and uses The fuel oil in the fuel storage cabinet 1 is transported to the fuel sedimentation tank 3 through the delivery pipeline 2; the daily fuel tank 5 communicates with the fuel sedimentation tank 3; the suction pipeline 6 connects the fuel storage tank 1 with the fuel sedimentation tank 3 and / or Or the daily fuel tank 5 is connected; the flow down pump 7 is arranged in the suction pipe 6 to make the heated fuel in the fuel settling tank 3 and / or the fuel daily tank 5 flow down to the fuel storage tank 1 . The heated fuel flows down through the suction main pipe 14 and mixes with the fuel in the fuel storage tank 1 to heat the fuel in the fuel storage tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com