Asphalt viscosity reduction modifier and manufacturing method thereof

A production method and modifier technology, which is applied in the field of asphalt modifiers, can solve the problems of energy consumption, soot and waste emissions, etc., and achieve the effects of reducing energy consumption, improving high temperature resistance, and reducing aging

Inactive Publication Date: 2012-01-11

重庆市广为道路材料有限公司

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] In recent years, the extensive use of modified asphalt and the increase in the compactness of asphalt pavement have increased the mixing and compaction temperature of asphalt mixture, resulting in energy consumption and waste such as smoke and dust during the production of asphalt mixture. significantly increased emissions

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

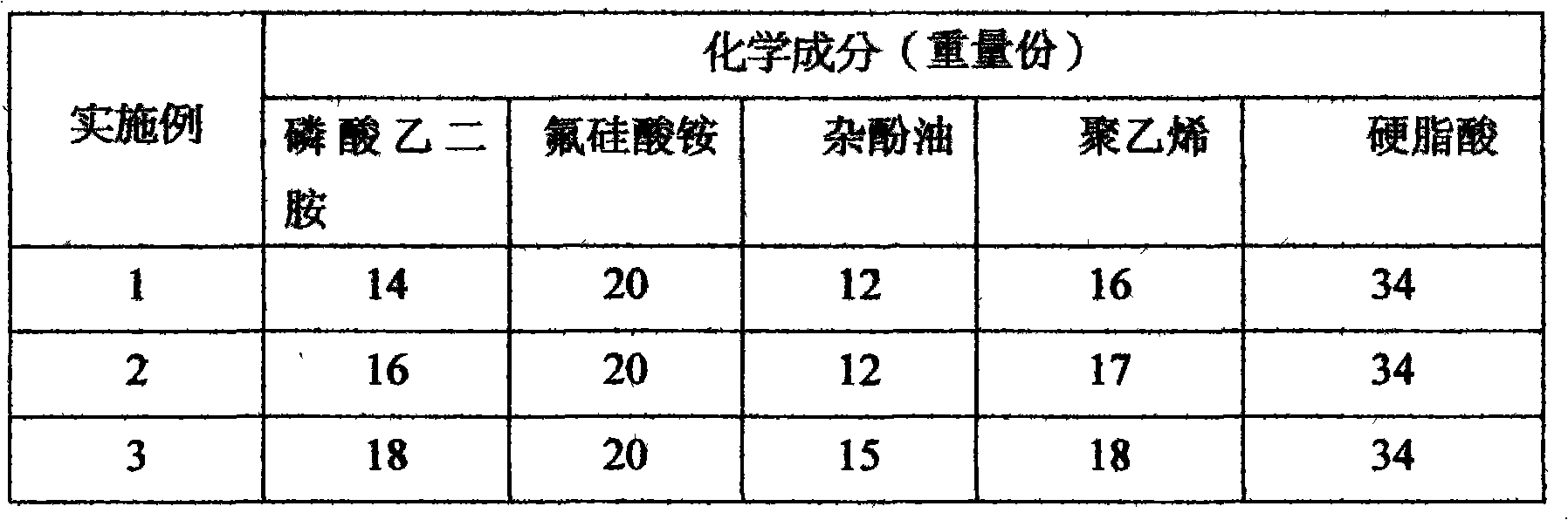

[0018] According to the materials and proportions described in Table 1, 500 g of the materials are placed into the reaction vessel, the temperature is raised to 250° C., and the reaction is fully stirred to complete the asphalt viscosity reducing modifier of the present invention.

[0019] Table 1: Chemical composition of an asphalt viscosity reducing modifier of the present invention

[0020]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

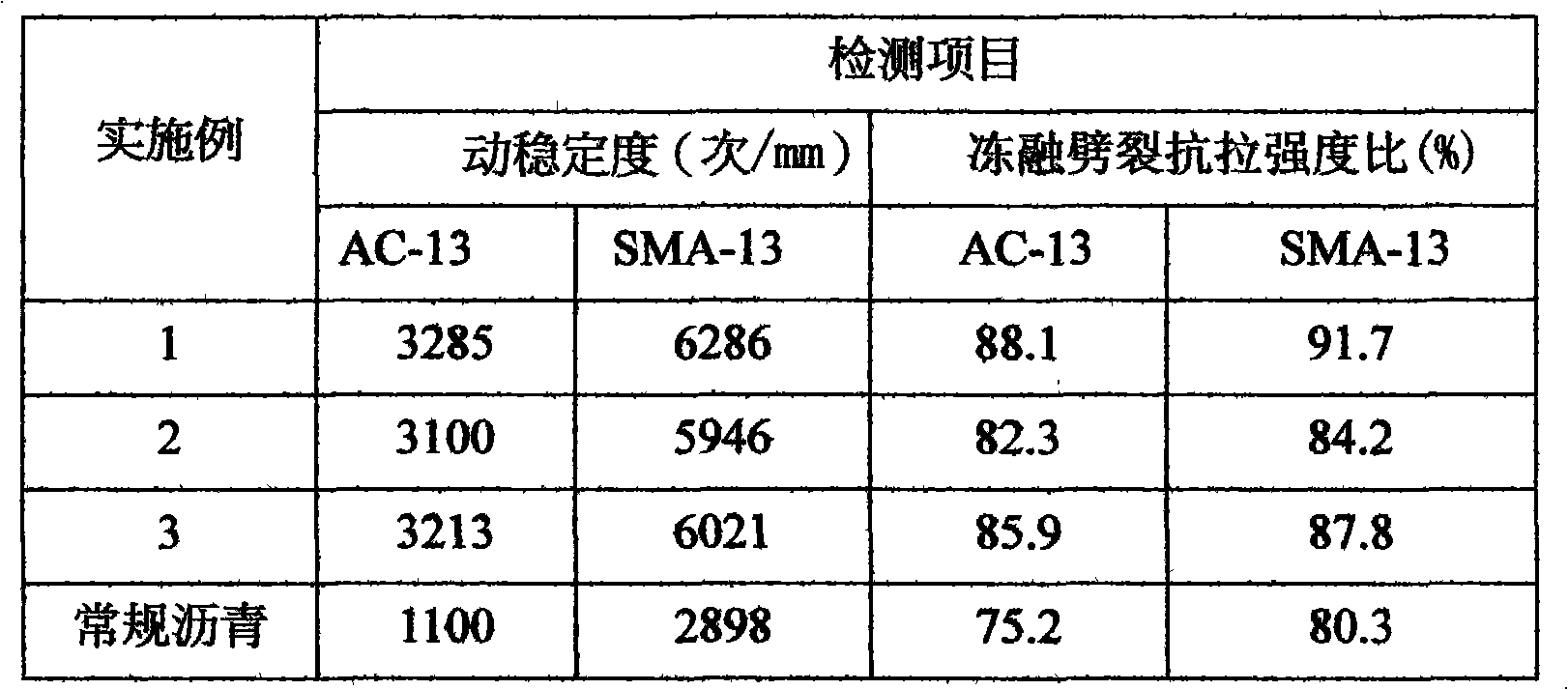

The invention relates to an asphalt viscosity reduction modifier, which is characterized in that the modifier comprises the following components in part by weight: 14-18 parts of activating agent, 20 parts of ammonium fluosilicate, 10-15 parts of kreosote, 15-18 parts of polyethylene and 34 parts of stearic acid. The manufacturing method comprises the steps that the components are added into a reaction container, the temperature is raised to 250 DEG C, and the asphalt viscosity reduction modifier disclosed by the invention is obtained after full stirring and reaction are completed. After the asphalt viscosity reduction modifier disclosed by the invention is simply mixed with asphalt, the asphalt viscosity can be obviously reduced, the construction temperature is reduced, poisoned dust emission is reduced, energy consumption is reduced, simultaneously the compaction of asphalt concrete can be obviously improved, the high temperature performance of the asphalt is improved, and the anti-aging capacity of the asphalt is obviously improved.

Description

【Technical Field】 [0001] The invention relates to an asphalt modifier, in particular to an asphalt viscosity reducing modifier and a manufacturing method thereof. 【Background technique】 [0002] In recent years, the extensive use of modified asphalt and the increasing requirements for the degree of compaction of asphalt pavements have increased the mixing and compaction temperature of asphalt mixtures, resulting in energy consumption and smoke and other wastes in the production of asphalt mixtures. The emissions of the country have increased significantly. As early as the 1990s, Japan, Europe and other countries signed the "Kyoto Protocol". These countries promised to significantly reduce greenhouse gas emissions. The hot-mix asphalt industry is also one of the targets that need to reduce emissions. At the end of 2009, at the Global Climate Change Conference held in Copenhagen, the meeting discussed the carbon dioxide emission reduction tasks of various countries and required al...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L95/00C08L23/06C08K13/02C08K5/5399C08K3/34C08K5/09

Inventor 段彦超

Owner 重庆市广为道路材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com