Bamboo batten filament pressing crusher

A crusher and wire pressing technology, which is applied in wood compression, wood processing equipment, manufacturing tools, etc., can solve problems such as cracking, wire jumping, and affecting the quality of the floor, so as to achieve uniform glue distribution, avoid wire jumping, and improve quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

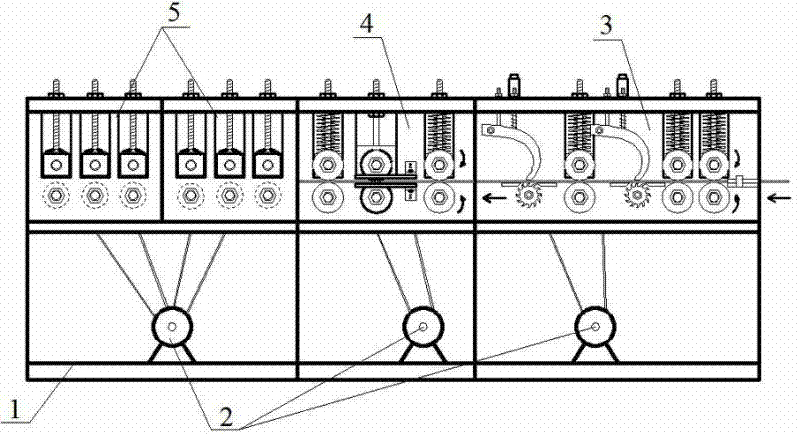

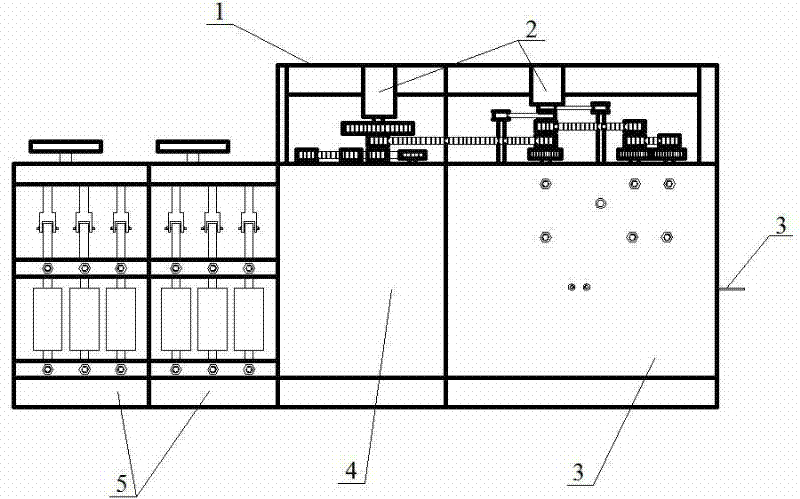

[0022] Such as figure 1 and figure 2 Shown, a kind of bamboo strip pressing wire crushing machine comprises base 1, motor 2, wire drawing machine 3, wherein also includes cutting machine 4 and crushing machine 5, described motor 2, wire drawing machine 3, cutting machine 4 And the crusher 5 is fixedly installed on the base, the feed port of the strip cutter 4 corresponds to the discharge port of the wire drawing machine 3, the feed port of the crusher 5 corresponds to the discharge port of the strip cutter 4, Motor 2 links to each other with drawing machine 3, strip cutting machine 4, crusher 5. The transmission between the wire drawing machine 3, the strip cutting machine 4, and the crusher 5 is realized by gears, chains and combinations thereof.

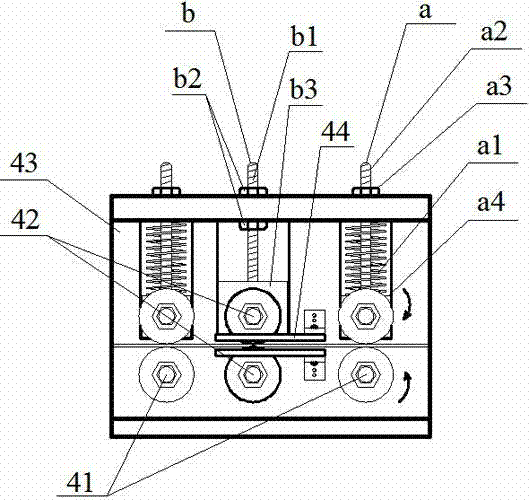

[0023] Such as image 3 As shown, the strip cutting machine 4 is composed of at least two sets of transmission wheels 41 that rotate up and down and one or more sets of vertical and counter-rotating strip cutting wheels 42. It...

Embodiment 2

[0031] Described strip cutting machine 4 is made up of 3 groups of drive wheels 41 that counter-rotate up and down and 2 groups of counter-rotating slitting wheels 42 up and down. Slitting wheel 42 is made up of 4 circular blades. The strip cutter 4 also includes two pairs of comb plates 44 . Other structures are the same as in Embodiment 1.

Embodiment 3

[0033] Described strip cutting machine 4 is made up of 4 groups of drive wheels 41 that counter-rotate up and down and 3 groups of strip-cutting wheels 42 that counter-rotate up and down. Slitting wheel 42 is made up of 5 circular blades. The strip cutter 4 also includes three pairs of comb plates 44 . Other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com