Bonding and potting method for aerial integrated motor

An integral, potting material technology, used in the field of gluing and potting, can solve the problems of large commutation sparks, easily affecting product performance, and the commutator cannot be separated from the surface of the shell, and achieves the effect of overcoming roundness deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

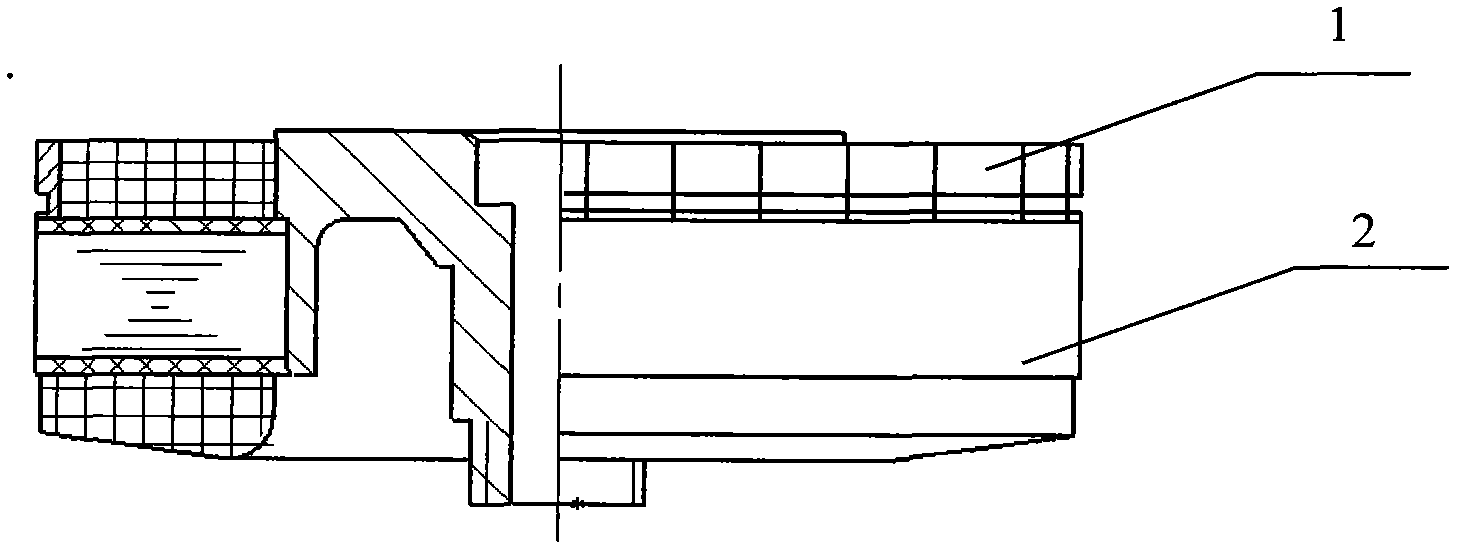

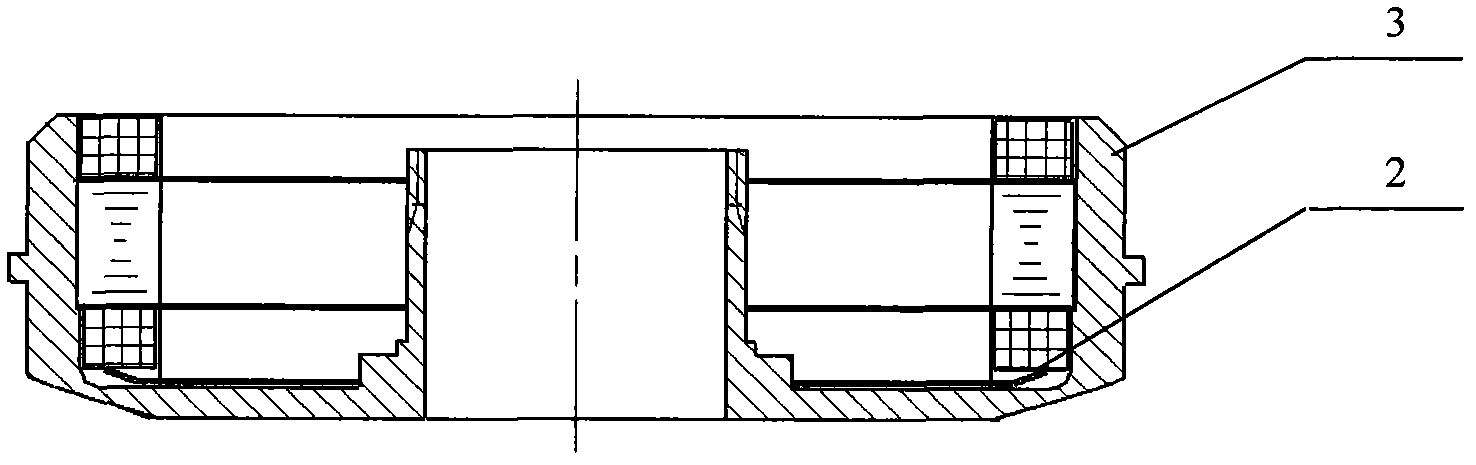

[0072] Example 1, ×××× overall motor potting:

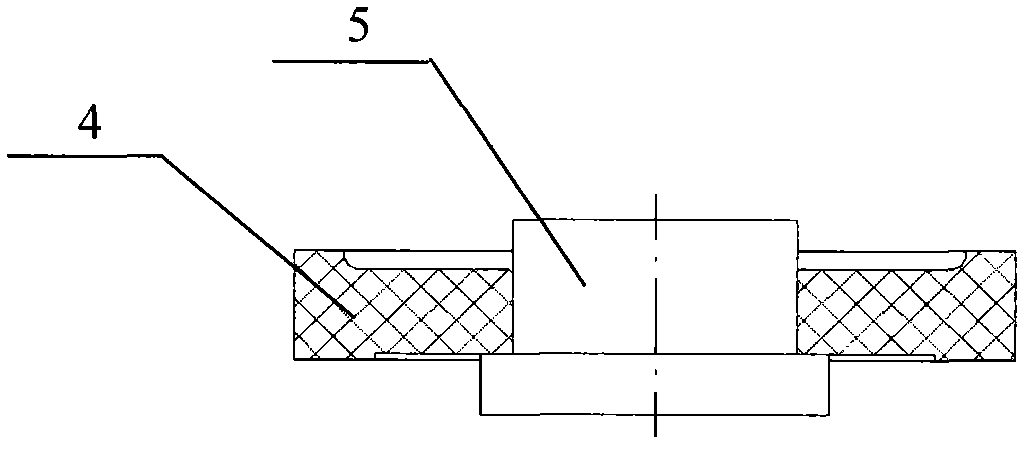

[0073] The elastic film potting mold is composed of an outer mold 4 and a positioning column 5. The outer mold 4 has a central hole, and the positioning column 5 is a cylinder with a step, which is installed on the central hole of the outer mold 4. One end of the outer mold 4 has a Counterbore, the inner diameter of which is the required outer diameter of the elastic film, and the depth is the required thickness of the elastic film;

[0074] The method of potting elastic film is as follows:

[0075] 1. Install the mold; put the positioning column 5 into the outer mold 4, seal the joint surface with silicone rubber, and place it at room temperature for more than 4 hours;

[0076] 2. Preheating; put the potting mold in a 60°C oven to preheat for 0.5h:

[0077] 3. Degassing; put the stirred elastic film potting material into the vacuum chamber to evacuate to remove air bubbles, start timing when the vacuum degree is less than 30Pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com