Core pulling and threading method for overhauling of large motor

A large-scale motor and core-through technology, which is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., can solve problems affecting the service life of motors, insulation damage, etc., and achieve the goal of reducing maintenance costs, reducing damage, and shortening maintenance cycles. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

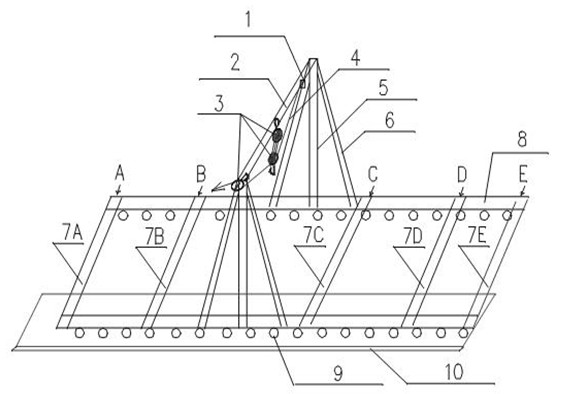

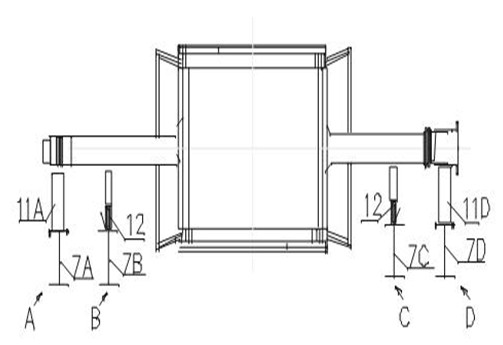

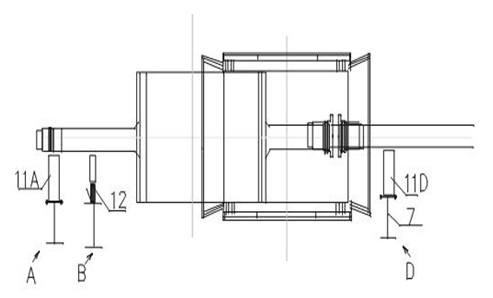

[0032] The method of pulling through the core of the large motor method proposed by the present invention will be further described with reference to the accompanying drawings.

[0033] Lay the steel plate next to the motor. The round steel is placed on the steel plate to form a slide. Place the on-site mast on the top of the round steel, hang the pulley block, use the hoist to pull the mast to remove the bearing seat, etc., and fasten the lower end of the traction wire rope to Lay a steel paper pad between the stator and the rotor on the stator lifting ears of the core-pulling motor. After lifting the stator and the rotor by 200mm~300mm, gently return the jack to lower the stator onto the four stator supports, and use the winch to pull the mast Move and cooperate with the electric hydraulic jack and other devices to pull the core and slowly move to the position to be lifted. After returning to the factory for inspection and repair, the core will be restored. The specific process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com