Multipoint SAW (surface acoustic wave) screen with locating axes with different frequencies

A surface acoustic wave and positioning axis technology, which is applied in the field of surface acoustic wave touch screens, can solve problems such as crosstalk between signals in different axes, achieve the effects of reducing screen interference, reducing processing difficulty, and facilitating signal processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

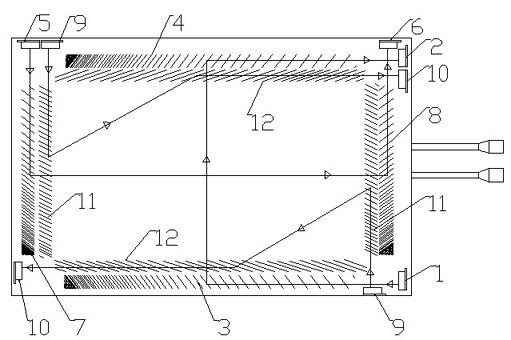

[0031] The dual-point touch screen is to add the Z axis on the basis of the X and Y axes of the single-point touch screen. The X and Y positioning axes are transmitted at a frequency of 4.5Mhz-3.5Mhz (the X and Y axes can also be transmitted at different frequencies) ); the Z positioning axis adopts the frequency transmission of 6Mhz-5Mhz, the specific method is as follows.

[0032] Adjust the reference frequency of the X and Y transmitting transducers to 4.5Mhz-3.5Mhz, the reference frequency of the X and Y receiving transducers to 4.5Mhz-3.5Mhz, and the frequencies of the X and Y transmitting stripe arrays and receiving stripe arrays at 4.5Mhz -3.5Mhz, according to V=f*λ, adjust the stripe array arrangement, and place the X, Y emitting stripe array and receiving stripe array at the upper and lower edges of the long side of the screen. The X, Y transmitting transducers and receiving transducers correspond to the X, Y transmitting and receiving fringe arrays.

[0033] Adjust th...

Embodiment 2

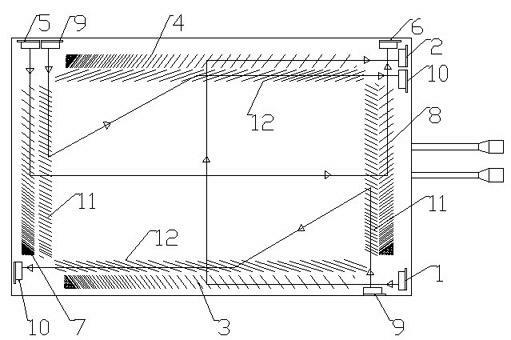

[0039] A multi-point surface acoustic wave screen with different frequencies for positioning axes, comprising a controller, an X-axis positioning device, a Y-axis positioning device, and a Z-axis positioning device, and any one of the X-axis positioning device, the Y-axis positioning device, and the Z-axis positioning device The shaft positioning device and the other two shaft positioning devices use different frequencies of sound wave transmission, and the longer the distance of the stripe array, the lower the sound wave frequency used.

[0040] In the X-axis positioning device, the reference frequency of the transmitting transducer and the receiving transducer is 3Mhz-2Mhz, and the frequency of the corresponding transmitting stripe array and receiving stripe array is 3Mhz-2Mhz; in the Y-axis positioning device, the transmitting transducer The reference frequency of the transmitter and the receiving transducer is 4.5Mhz-3.5Mhz, and the frequency of the corresponding transmitti...

Embodiment 3

[0044] A multi-point surface acoustic wave screen with different frequencies for positioning axes, comprising a controller, an X-axis positioning device, a Y-axis positioning device, and a Z-axis positioning device, and any one of the X-axis positioning device, the Y-axis positioning device, and the Z-axis positioning device The shaft positioning device and the other two shaft positioning devices use different frequencies of sound wave transmission, and the longer the distance of the stripe array, the lower the sound wave frequency used.

[0045] In the X-axis positioning device, the reference frequency of the transmitting transducer and the receiving transducer is 4.5Mhz-3.5Mhz, and the frequency of the corresponding transmitting stripe array and receiving stripe array is 4.5Mhz-3.5Mhz; in the Y-axis positioning device , the reference frequency of the transmitting transducer and the receiving transducer is 6Mhz-5Mhz, and the frequency of the corresponding transmitting stripe a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com