Method for detecting interlocking function of bearing lubricating oil pump of turbine during starting of APS (Advanced Planning System)

A lubricating oil pump and bearing oil technology, applied in the direction of engine lubrication, engine components, lubricating parts, etc., to achieve the effect of ensuring controllability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

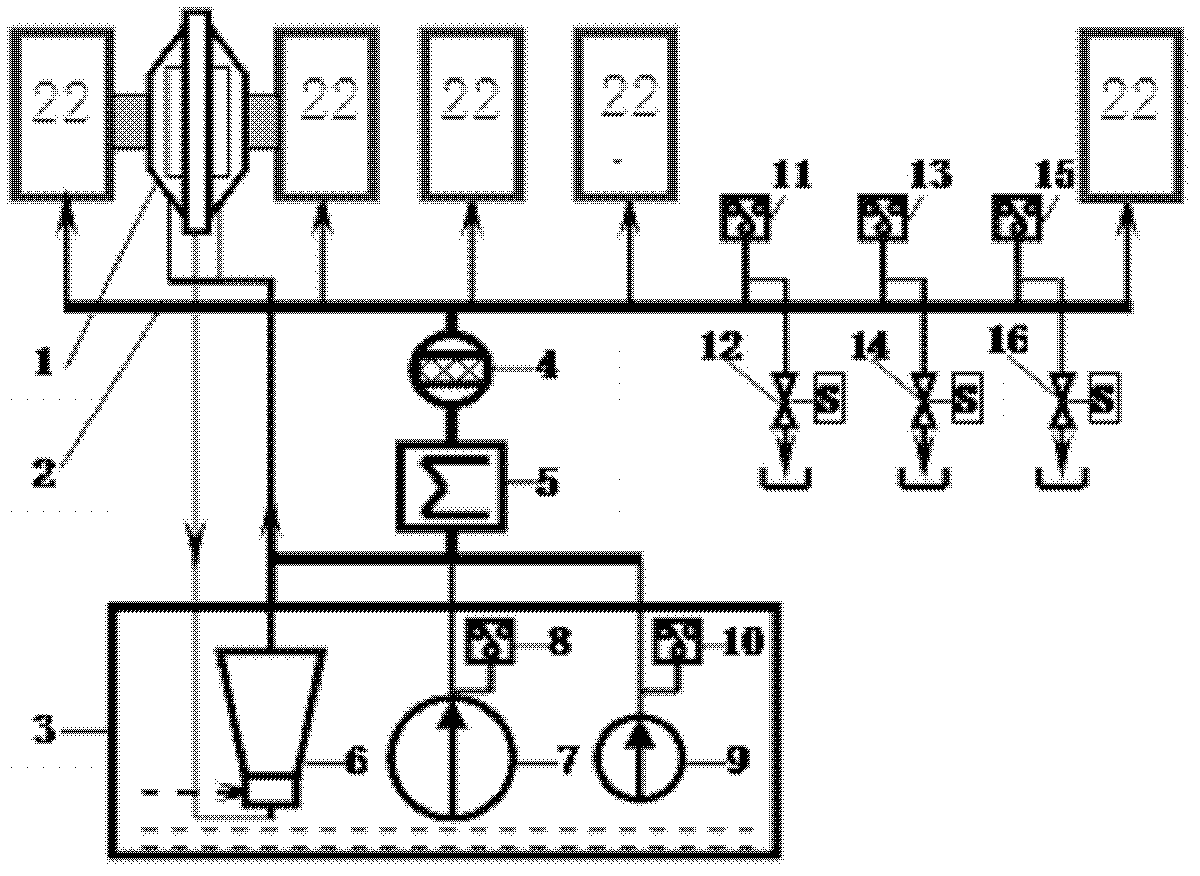

Method used

Image

Examples

Embodiment 1

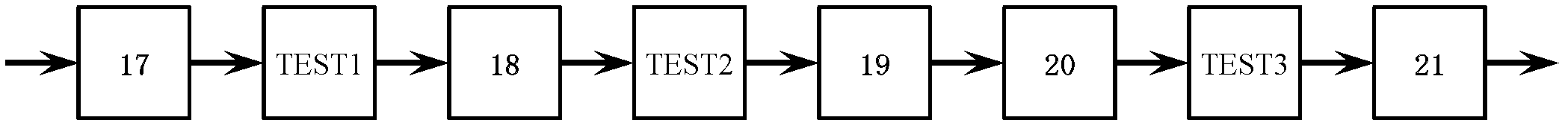

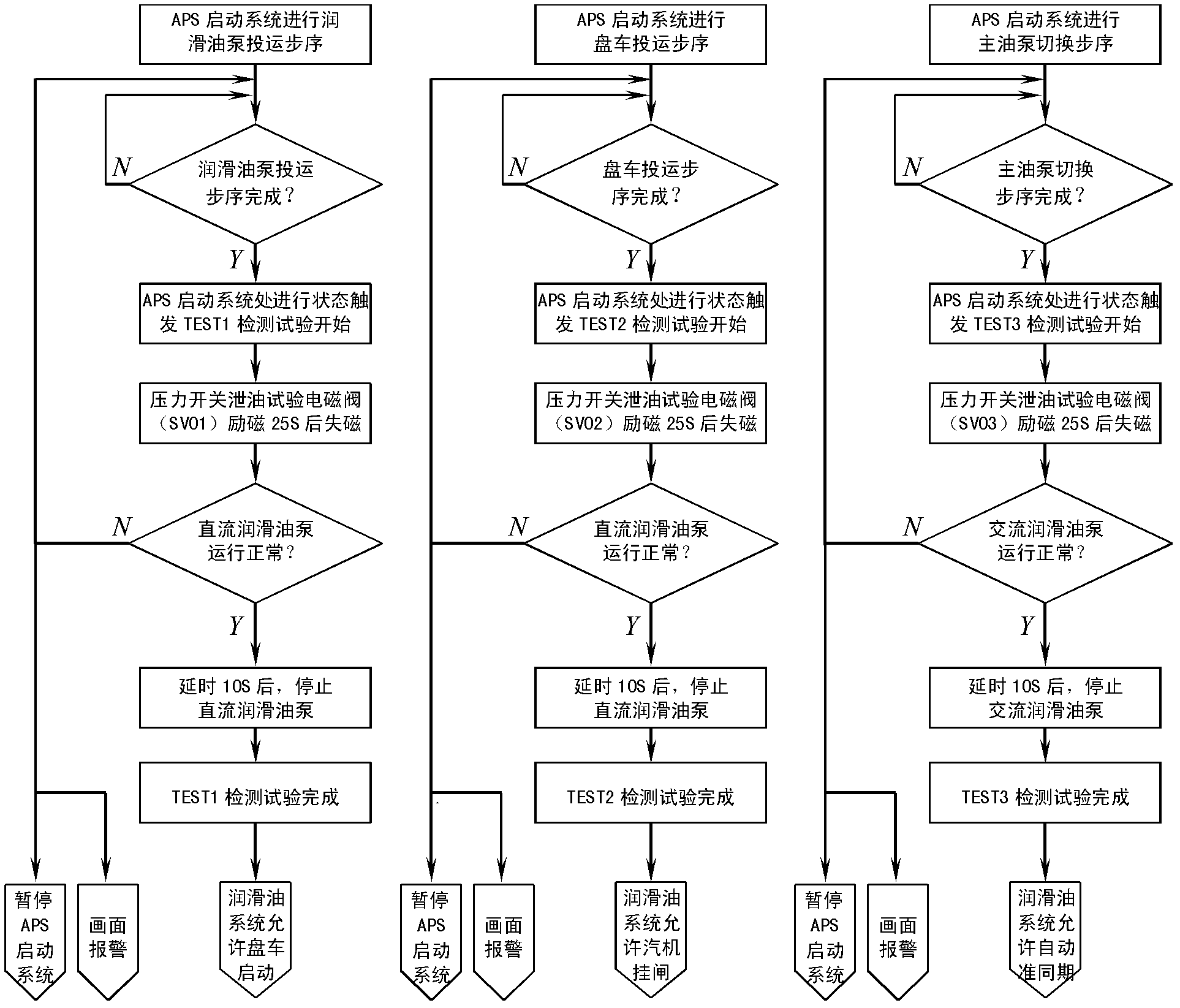

[0079] A certain 600MW unit implements the technical scheme according to the present invention ( image 3 ) for detection, the detection process method is as follows:

[0080] During the start-up process of the unit using APS mode, the operation sequence of the turbine bearing lubricating oil pump is carried out;

[0081] When the DCS collects that the AC lubricating oil pump is running and reaches the output condition (>0.9MPa, the PSA contact is closed), the DC lubricating oil pump is in the standby state, and the APS starts the system when the signal is not suspended, then start TEST1 detection;

[0082] SV01 demagnetizes after 25 minutes of excitation; check the operation of the DC lubricating oil pump; if the DC lubricating oil pump is running and reaches the output condition (> 0.85MPa PSB contact closed), stop the DC lubricating oil pump after a delay of 10 seconds, and give TEST1 detection completed and the bearing lubricating oil system meets the requirements for cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com