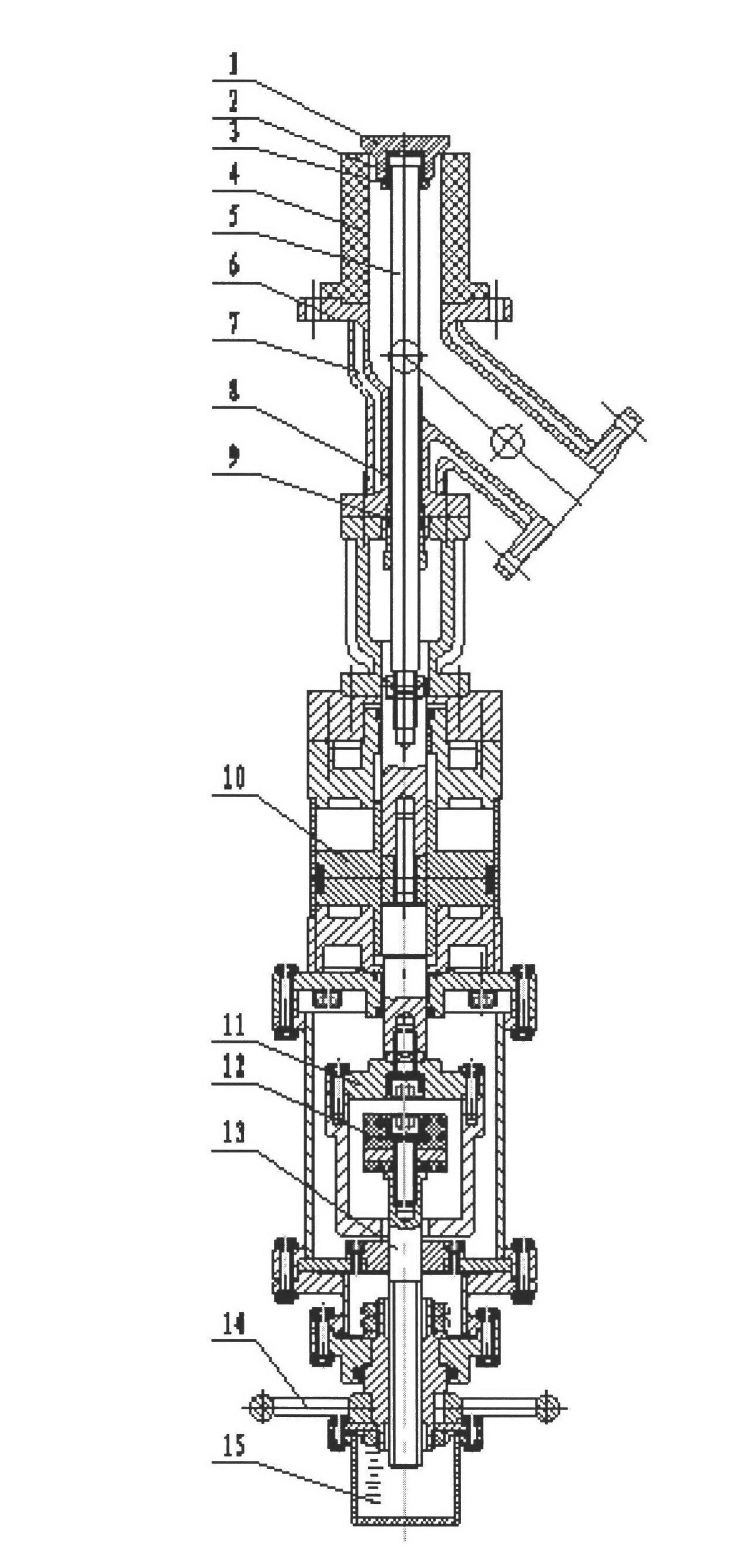

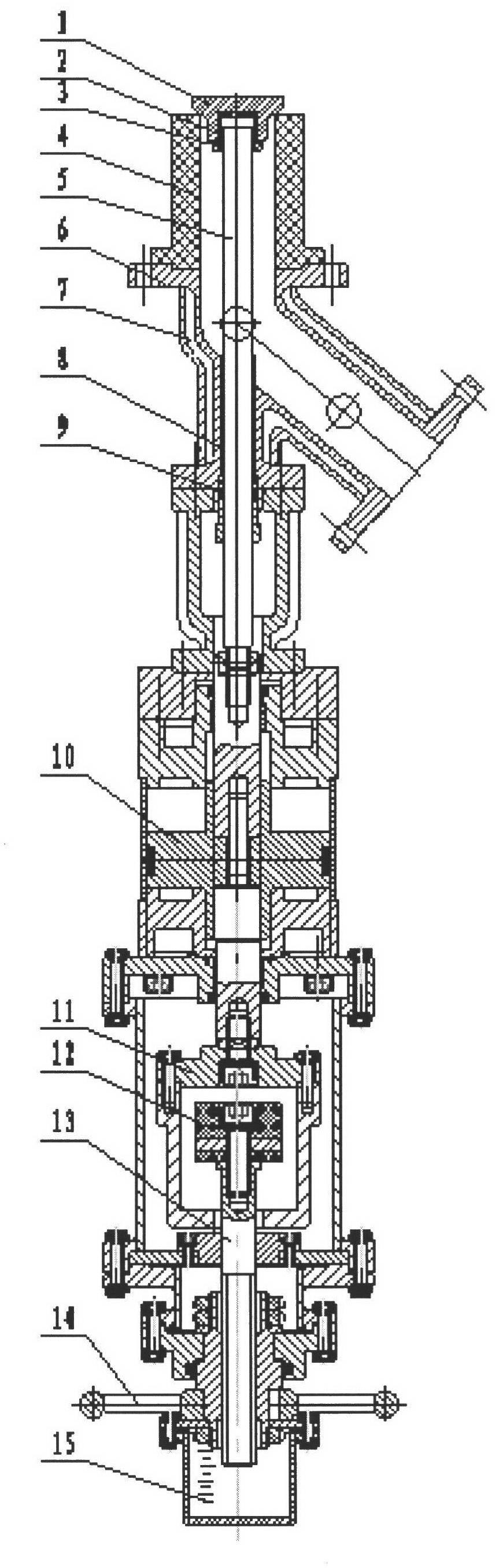

Automated liquid explosive discharging device

A discharging device and explosive technology, which is applied to valve devices, valve heating/cooling devices, engine components, etc., can solve the problem of not meeting the special requirements of liquid explosives, and can prevent the entry of explosive dust, avoid accidents, and seal reliably. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The spool is composed of a spool head 1, a copper inner sleeve 2, and a sealing ring 3. The spool and the valve stem 5 are connected by a movable seal, so that during the movement of the valve stem 3, if it is not coaxial with the PTFE sleeve 4, it can still maintain The valve core is sealed with the PTFE sleeve 4. The PTFE sleeve 4 is installed at the bottom of the melting or mixing tank. The valve body 6 is cast from stainless steel and is a double-layer jacket structure. There will be no solidification in the material, and the discharge port adopts a flange structure, which is convenient for connection. A PTFE guide sleeve 8 is used in the sliding part of the valve stem and the valve body to prevent friction between metals. The seal of the valve stem is sealed with PTFE packing seal 9, the drive of the valve stem is driven by the cylinder 10, the cylinder piston is equipped with a magnetic ring, and the pull rod outside the cylinder is equipped with an intrinsically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com