Deep water pipeline composite polyurethane elastomer heat insulation layer casting molding device

A technology for composite polyurethane and deep-water pipelines, which is applied in the field of polyurethane elastomer insulation layer pouring and molding devices, which can solve the problems of poor quality of pouring products and unreasonable pouring and molding operations of polyurethane insulation layers, so as to reduce time and cost and reduce processing difficulty , the effect of improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

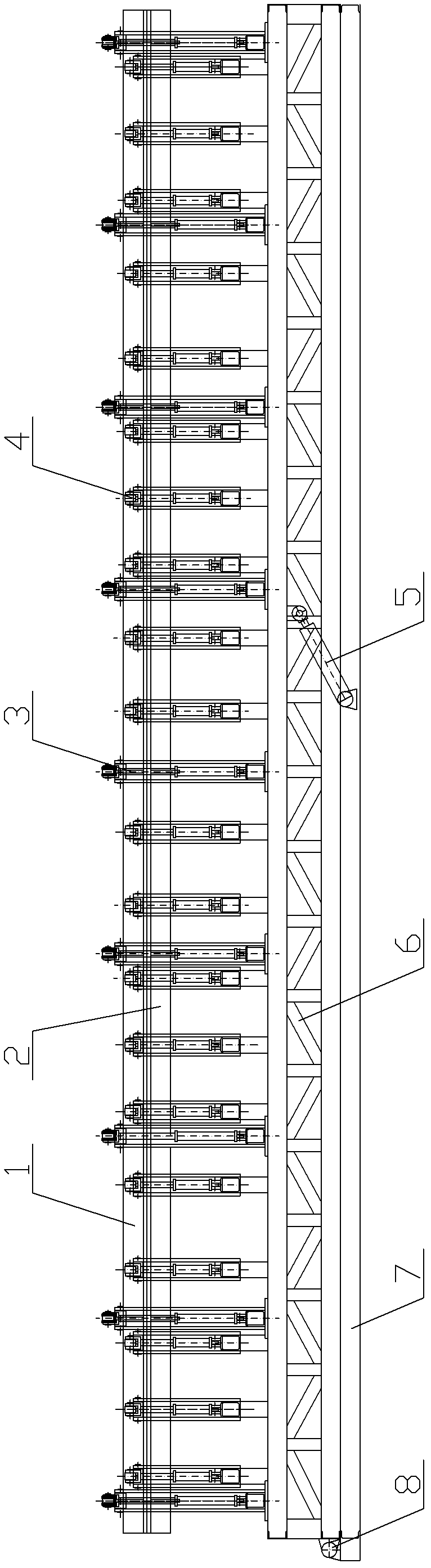

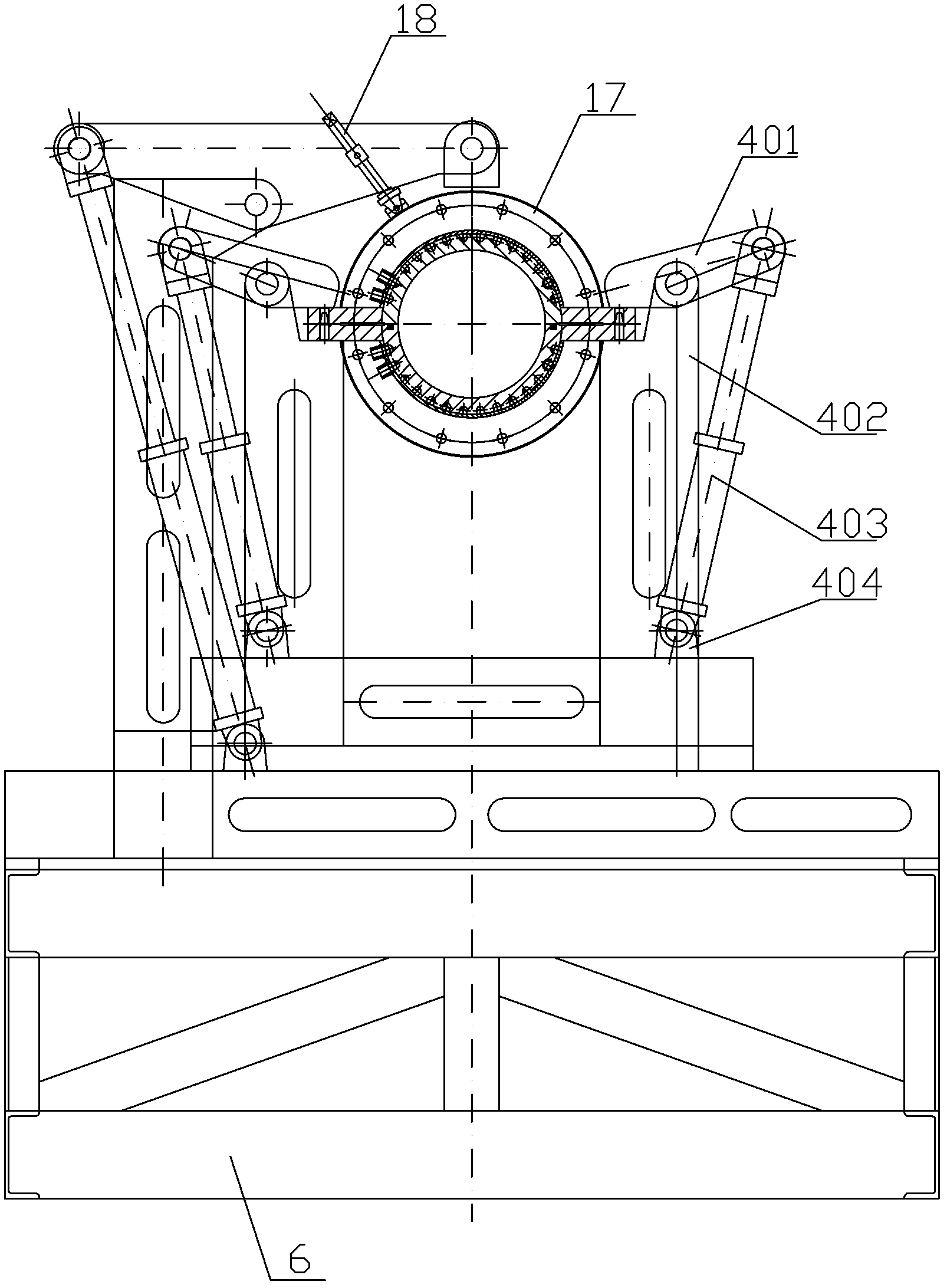

[0043] This embodiment discloses a deep-water pipeline composite polyurethane elastomer insulation layer pouring molding device, which consists of a mold, a mold opening device 3, a mold clamping device 4, a rotating and tilting support 6, a base 7, an inclination control device 5, a hydraulic station 9, a heating Temperature control device 10 etc. are formed.

[0044] Such as figure 1 As shown, the total length of the mold in this embodiment is 12.5 meters, and it is a split semicircular mold made up of an upper mold 1 and a lower mold 2. The mold is made of mold steel, and the outside of the mold steel is coated with polyurethane insulation material, and the outside of the polyurethane insulation layer is coated with stainless steel plate.

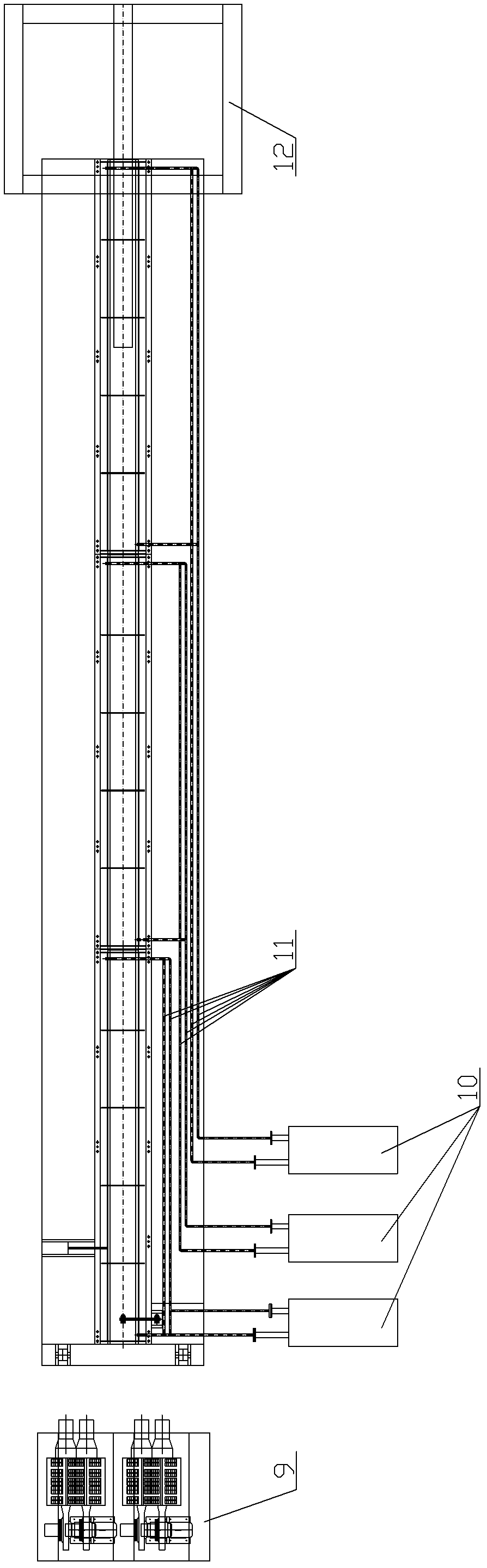

[0045] Such as figure 2 As shown, the mold is uniformly composed of three sections in the axial direction, every two sections of upper mold 1 components are connected by flange 17, and every two sections of lower mold 2 components are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com