Photovoltaic device and method for manufacturing thin-film solar cell

A technology of solar cells and manufacturing methods, applied in photovoltaic power generation, final product manufacturing, energy conversion devices, etc., can solve the problems of photovoltaic cell surface damage, low production capacity, etc., achieve high-precision patterning, simplify manufacturing, and reduce manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A number of different embodiments are provided due to the different features of the present invention. The specific elements and arrangements in the present invention are for simplification, but the present invention is not limited to these embodiments. For example, the description of forming the first element on the second element may include an embodiment in which the first element is in direct contact with the second element, and also includes an additional element formed between the first element and the second element so that the An embodiment where one element and the second element are not in direct contact. In addition, the present invention is represented by repeated element symbols and / or letters in different examples for the sake of simplification and clarity, but does not indicate the relationship between the various embodiments and / or structures.

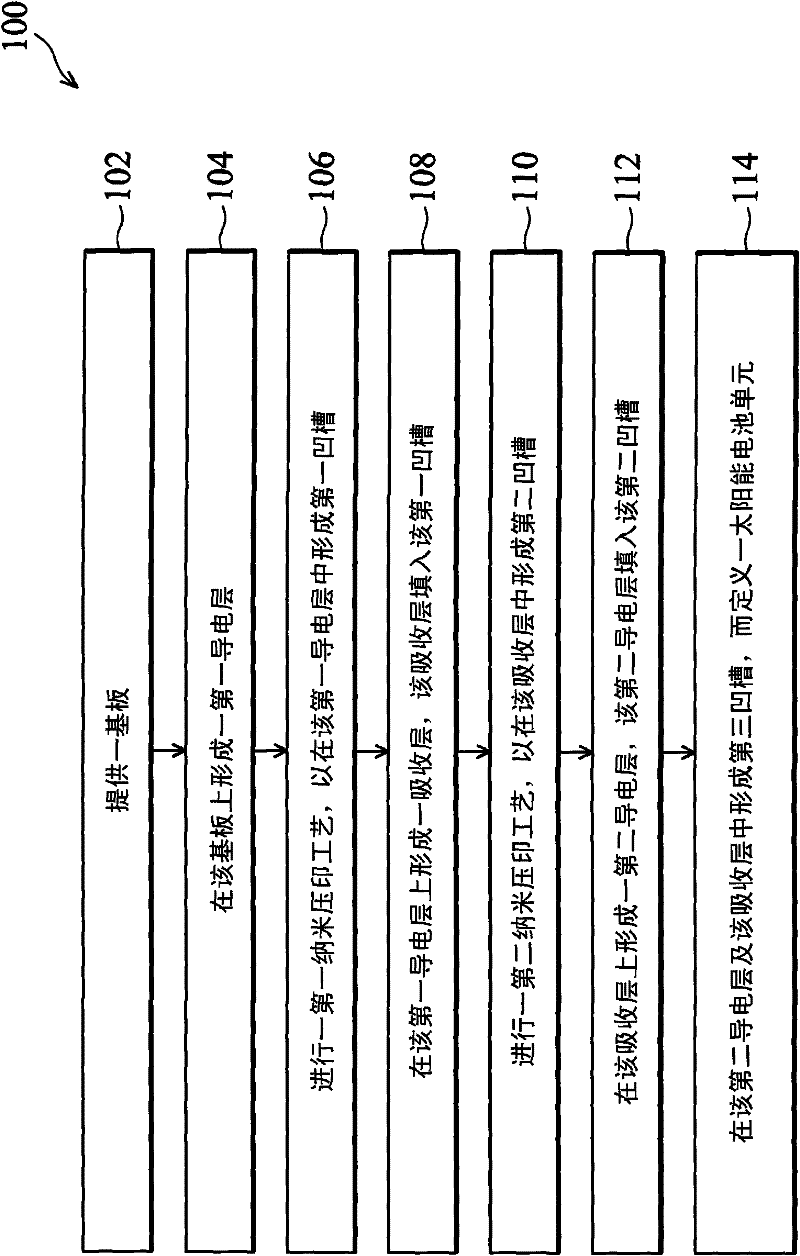

[0030] Traditionally, when preparing photovoltaic devices, laser or mechanical cutting is used to define, wire, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com