A method for measuring the weight of pretreatment film of color-coated board

A measurement method and pretreatment technology, which is applied in the pretreatment field of color-coated plate detection, can solve the problems of longer digestion time, complicated sample sealing, and high film weight measurement value, so as to achieve strong sample digestion ability, ensure accuracy, and sample Closed and easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

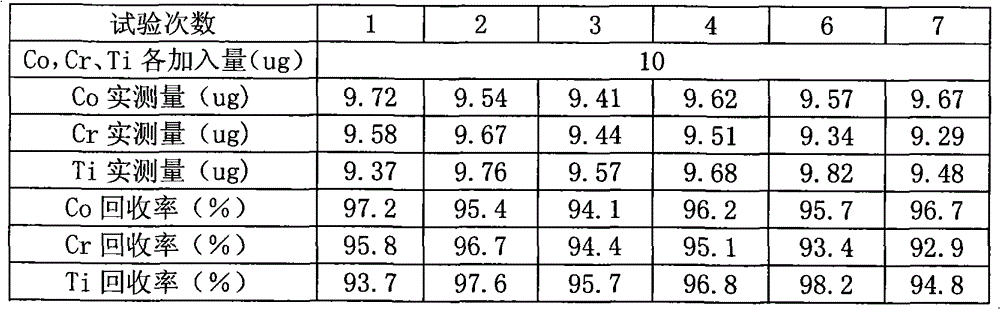

Examples

Embodiment Construction

[0014] Below, the present invention will be further described by means of specific embodiments:

[0015] A method for measuring the weight of a color-coated pretreatment film, which includes the following steps: sample sealing: put the non-measurement side of the sample downward into a rubber sample dissolving cup, press it tightly with your hands, so that all the edges of the sample sheet are sunk into the In the rubber sample dissolving cup;

[0016] Sample stripping: add 10ml of hydrochloric acid-hexamethyltetramine corrosion solution to the sample dissolution cup, and after the reaction is calm, transfer the stripping solution to a 100ml steel volumetric flask, rinse the surface of the sample with water for 3 to 4 times, and transfer the rinse solution to into a 100ml steel volumetric flask;

[0017] Digestion sample: Add 2ml of nitric acid and 2ml of hydrogen peroxide into a 100ml steel volumetric flask, heat and boil for 10min;

[0018] Measurement solution preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com