Atmosphere furnace pressurized air seal device

A pressurized gas and atmosphere furnace technology, applied in the field of machinery, can solve the problems of gas leakage, waste gas, limited effect, etc., and achieve the effect of strengthening the gas seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

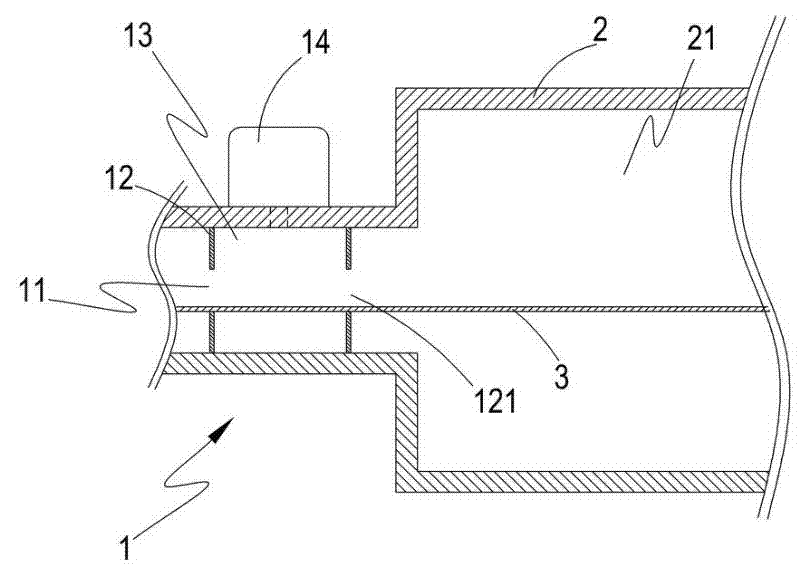

[0019] as attached figure 1 As shown, it is a cross-sectional view of a preferred embodiment of the present invention. From the figure, it can be clearly seen that the present invention mainly includes a gas sealing device 1 and a body of furnace 2 connected with the gas sealing device 1, and the body of furnace 2 is further an atmosphere. Furnace, and the gas sealing device 1 is provided with a channel 11, the channel 11 communicates with the furnace chamber 21 in the furnace body 2, and there are a plurality of barrier parts 12 in the channel 11 to block the formation of the accommodating chamber 13, The accommodating chamber 13 is pressurized by a gas pressurizing device 14, and each of the barrier parts 12 is respectively provided with a delivery port 121, and the delivery port 121 and the accommodating chamber 13 pass through a The conveying device 3 extending from the furnace body 2 .

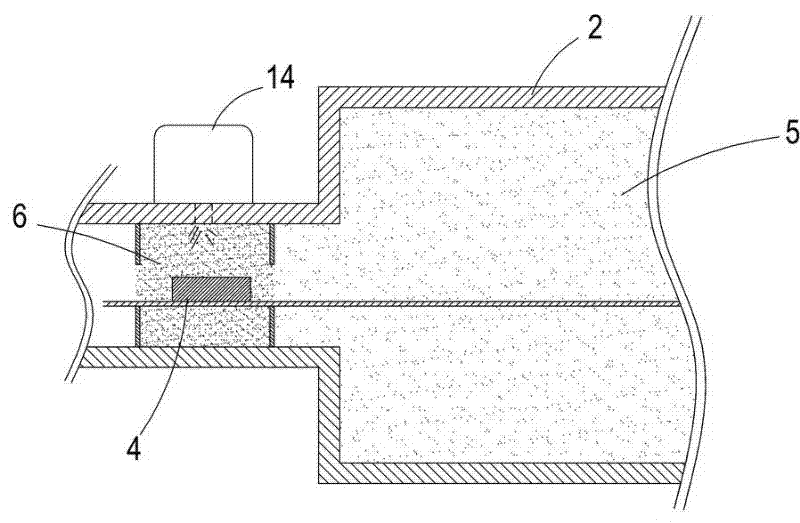

[0020] as attached figure 1 to attach image 3 Shown is a cross-sectional view and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com