Instantaneous electric kettle heating body

A heating body, electric kettle technology, applied in the direction of fluid heaters, lighting and heating equipment, etc., can solve the problems of small heat transfer heat resistance, small heat capacity, small volume, etc., to achieve small heat transfer heat resistance, small heat capacity, cavity Small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

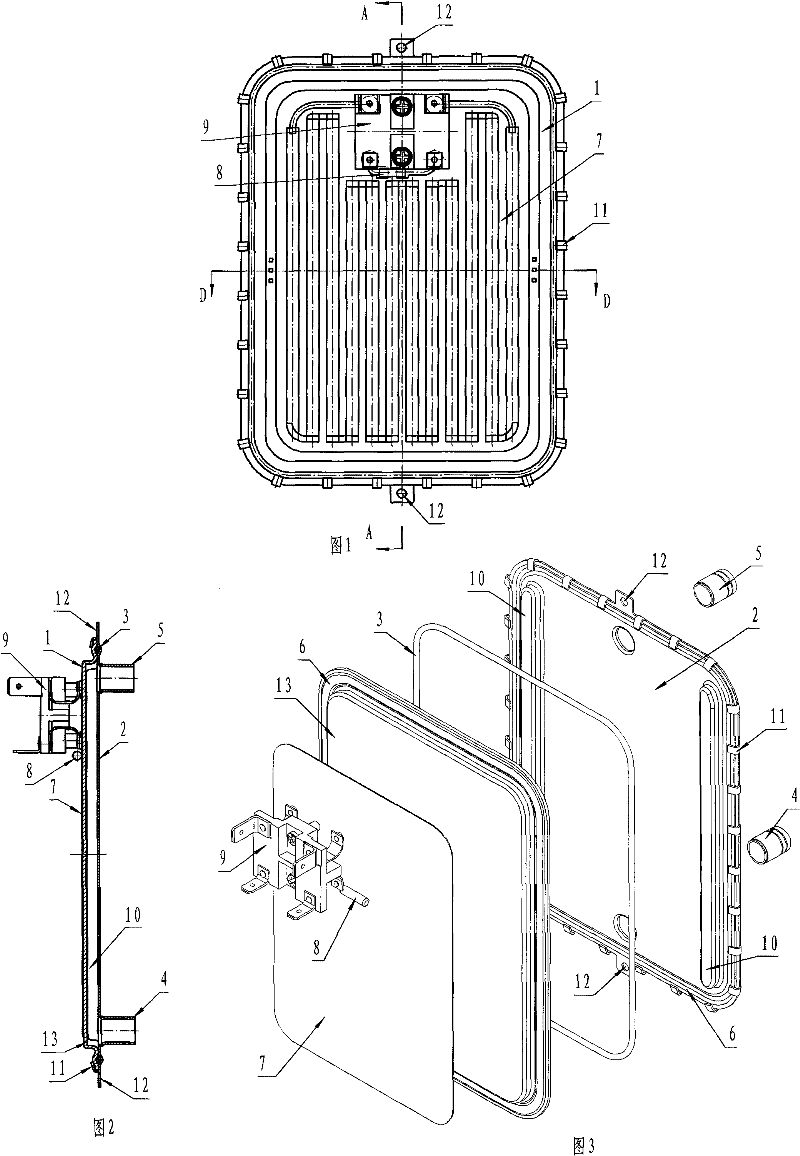

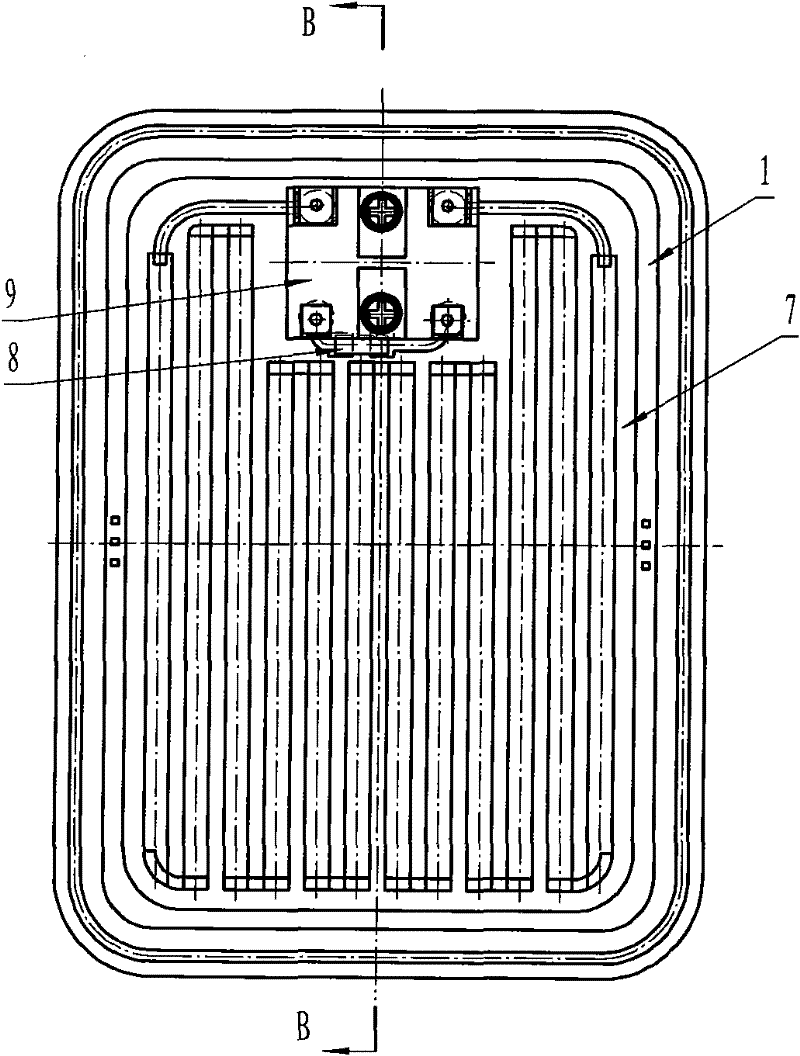

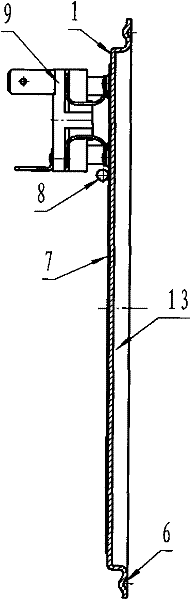

[0018] Press with 1.2mm stainless steel plate Figure 4 and Figure 5 The shape of the heating plate is processed, the overall size is 148mm×109.6mm, the inner cavity size is 131.4mm×93mm, and the inner cavity depth is 4mm. The electric heating film is processed on the outside of the heating plate and the thermistor and connector are installed; use 0.6mm stainless steel plate according to Figure 6 and Figure 7 The shape of the rear plate of the heating body is processed. The overall size is 148mm×109.6mm. There are 28 tooth-shaped mounting buckles. The height of the two bosses is 3.8mm, the length is about 128mm, and the width is about 7mm. Joint and water outlet joint; place a sealing ring in the groove of the heating plate, and then cover the back plate of the heating body on the heating plate. connector also facing outwards, then press the toothed mounting buckles as Figure 8 The structure shown is bent and pressed tightly, so that the heating plate and the rear plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com