Method for making layered visual effect of plastic electroplating

A visual effect, plastic electroplating technology, applied in the field of layered visual effect manufacturing method, can solve the problems of easy wear and tear, undisclosed and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The content, characteristics and embodiments of the present invention are described below with the help of drawings, so that your examiners can have a better understanding of the present invention.

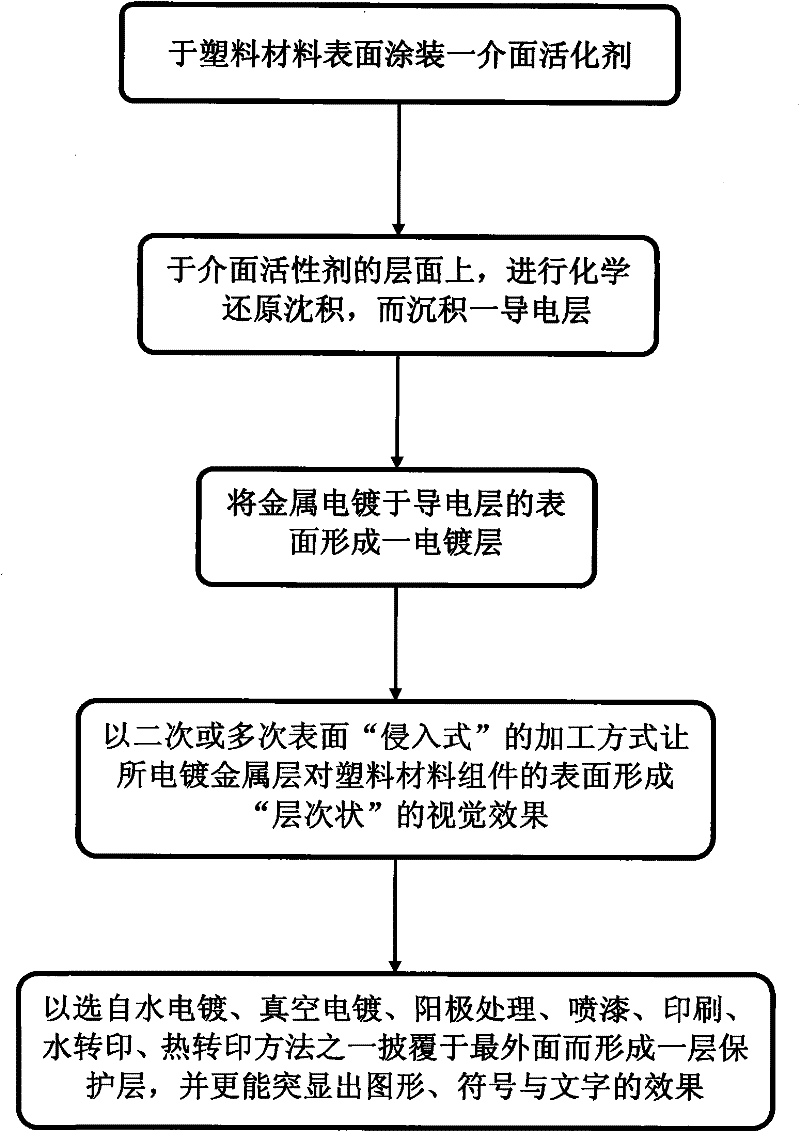

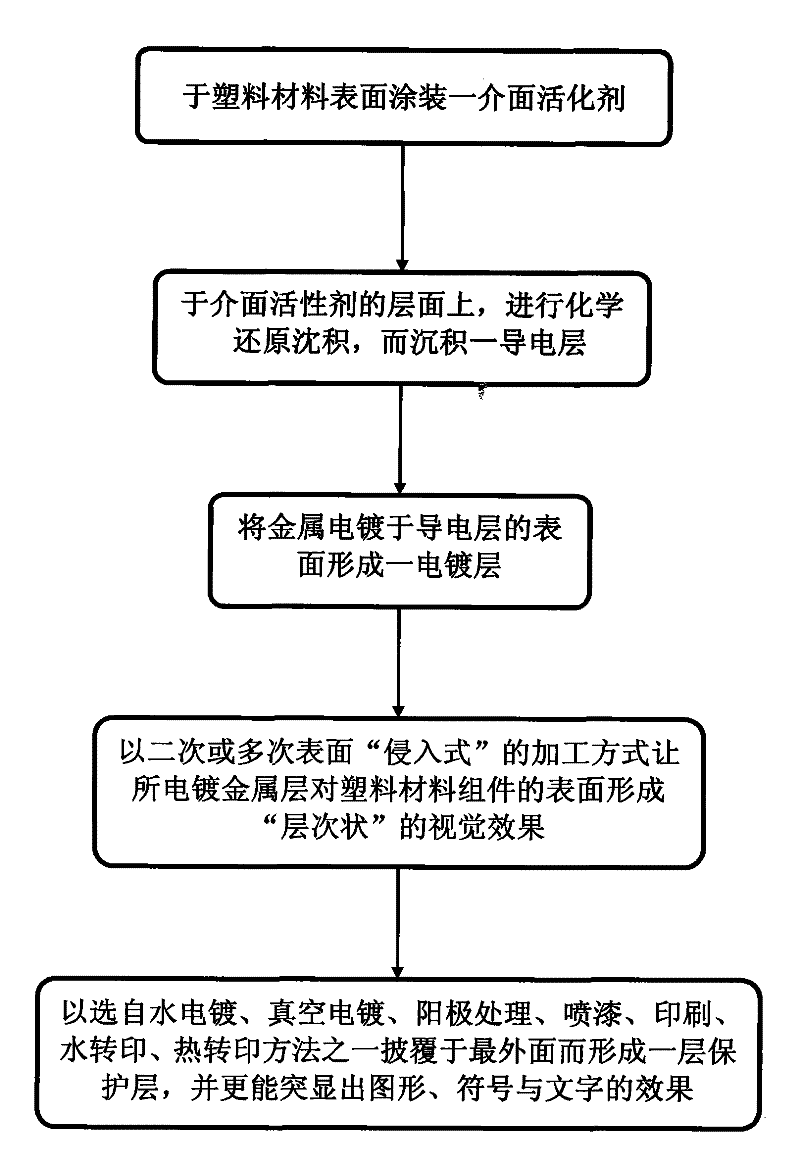

[0020] see figure 1 Shown, plastic material surface electroplating process of the present invention at least comprises the following steps:

[0021] (a) Coating an interface activator on the surface of the plastic material; as a dispersing (DISPERSING) Surfactant, because the surfactant has the characteristics of uniform dispersion, it is used to control the quality of the color and the stability of the product. At the same time, it can also make the surface of the electroplated plastic material more fully interact with the metal and the electrolytic liquid.

[0022] (b) On the surface of the surfactant, chemical reduction deposition is carried out to deposit a conductive layer (film film). The metal of the conductive layer can be any one of nickel, copper, silver, cobalt,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com