A cross-scale in-situ particle reinforced aluminum matrix composite material and its preparation method

An aluminum-based composite material and particle-reinforced aluminum technology are applied in the field of cross-scale in-situ particle-reinforced aluminum-based composite materials and their preparation, which can solve the problem of high volume fraction, achieve low reaction temperature, strong designability, and aluminum burning loss. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] It is required to prepare nano-Al 2 o 3 Particle volume fraction is 1.5%, micron (Si+Al 3 Ti) particle volume fraction of 6% cross-scale in-situ particle-reinforced aluminum matrix composites, the Al-10wt% Si alloy is melted, and SiO is added at 10wt% of the Al-Si alloy 2 For melting, heat up to 800 o About C, keep warm for 10 minutes and then refine, add 0.3% (P+S) composite modifier and cool down to 710°C, then use a frequency of 20kHz and a power density of 400W / cm 2 Ultrasonic treatment of the melt for 25 minutes, adding 1wt% titanium powder and 0.3wt% rare earth while ultrasonic treatment, standing for 5 minutes, then removing slag, adjusting the temperature and pouring, and finally forming (Si+Al 3 Ti+Al 2 o 3 ) reinforced aluminum matrix composites.

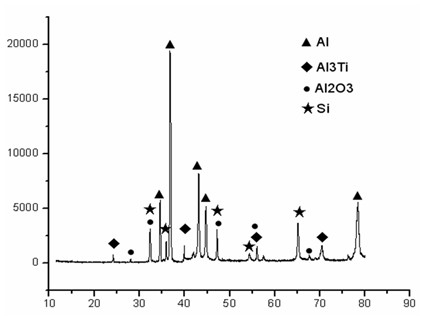

[0025] figure 1 XRD pattern of cross-scale in-situ particle reinforced aluminum matrix composites, it can be seen that the main reinforcement phase is (Si+Al 3 Ti+Al 2 o 3 ).

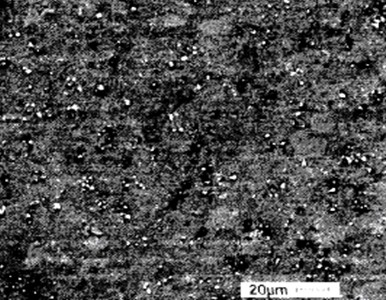

[0026] figure 2 The SEM i...

Embodiment 2

[0030] It is required to prepare nano-Al 2 o 3 Particle volume fraction is 3%, micron (Si+Al 3 Ti) particle volume fraction of 9% cross-scale in-situ particle-reinforced aluminum matrix composites, the Al-15wt% Si alloy is melted, and SiO is added at 18wt% of the Al-Si alloy 2 Melt, heat up to 850°C, heat for 5 minutes and then refine, add 1% (P+S) composite modifier and cool down to 810°C, then use a frequency of 20kHz and a power density of 1200W / cm 2 Ultrasonic treatment of the melt for 15 minutes, adding 1.5wt% titanium powder and 0.5wt% rare earth while ultrasonic treatment, standing for 10 minutes, then removing slag, adjusting the temperature and pouring, and finally forming (Si+Al 3 Ti+Al 2 o 3 ) reinforced aluminum matrix composites.

[0031] Analysis showed that Al 2 o 3 、Al 3 The volume fractions of Ti and Si particles are 3.1%, 1.2%, and 8.0%, respectively. Under the test conditions of a load of 3.0MPa and a sliding speed of 200r / min, after quenching and l...

Embodiment 3

[0034] It is required to prepare nano-Al 2 o 3 Particle volume fraction is 4%, micron (Si+Al 3 Ti) The cross-scale in-situ particle reinforced aluminum matrix composite with a particle volume fraction of 4%, melted the Al-3wt% Si alloy, and added SiO at 25wt% of the Al-Si alloy 2 Melt, heat up to 830°C, heat for 8 minutes and then refine, add 0.6% P-Cu master alloy and cool down to 760°C, then use frequency 20kHz, power density 800W / cm 2 Ultrasonic treatment of the melt for 20 minutes, adding 2wt% titanium powder and 0.4wt% rare earth while ultrasonic treatment, standing for 8 minutes, then removing slag, adjusting the temperature and pouring, and finally forming (Si+Al 3 Ti+Al 2 o 3 ) reinforced aluminum matrix composites.

[0035] Analysis showed that Al 2 o 3 、Al 3 The volume fractions of Ti and Si particles are 3.9%, 1.6%, and 2.6%, respectively. Under the test conditions of a load of 2.0MPa and a sliding speed of 200r / min, after quenching and low temperature

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com