Carbon nanotube/poly-Schiff base polymer and its preparation method and application

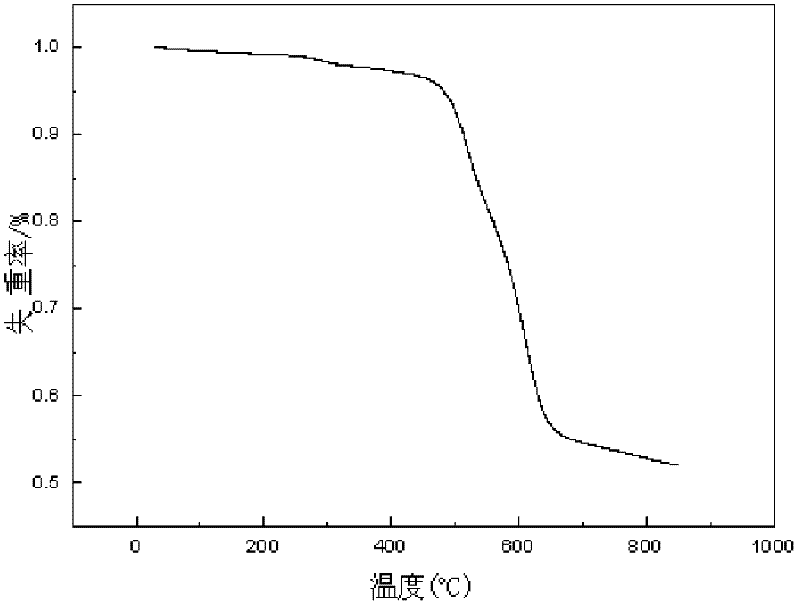

A polySchiff base and carbon nanotube technology, applied in chemical instruments and methods, color-changing fluorescent materials, etc., can solve the problems of poor thermal stability and low photochromic response sensitivity, achieve good thermal stability, improve luminescence performance, The effect of good high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

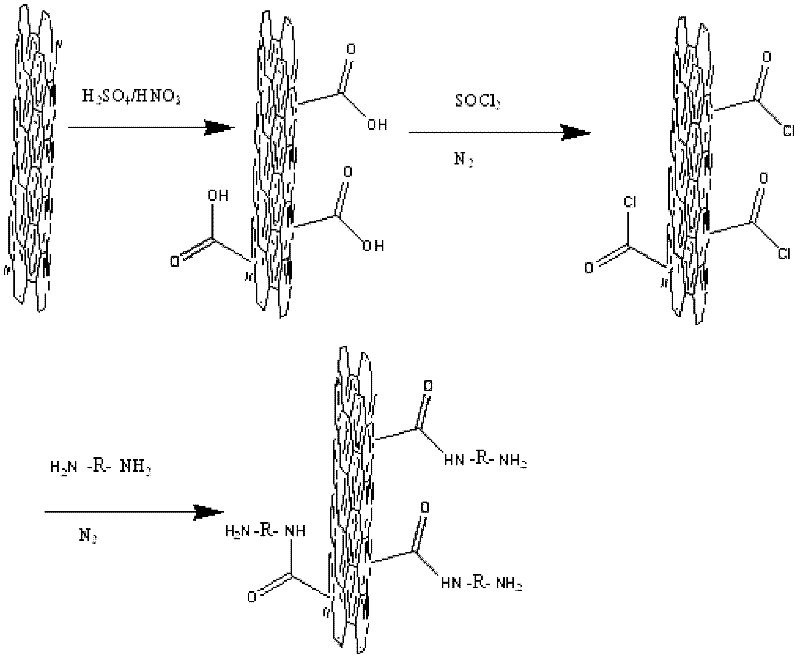

[0034] Embodiment 1: In this embodiment, the carbon nanotube / poly-Schiff base polymer is that the poly-Schiff base is grafted onto the carbon nanotube, and is obtained by aminating the carbon nanotube, the aromatic diamine monomer and the dialdehyde group The compound is obtained by in-situ polymerization, wherein the molar ratio of the aromatic diamine monomer and the dialdehyde compound is 1:1, and the mass of the aminated carbon nanotube is 1% of the mass of the aromatic diamine monomer and the dialdehyde compound. %~10%.

[0035] In this embodiment, the aminated carbon nanotubes are prepared by using the conventional method disclosed now, for example, the carbon nanotubes are obtained after surface oxidation, acyl chloride and amination treatment in sequence.

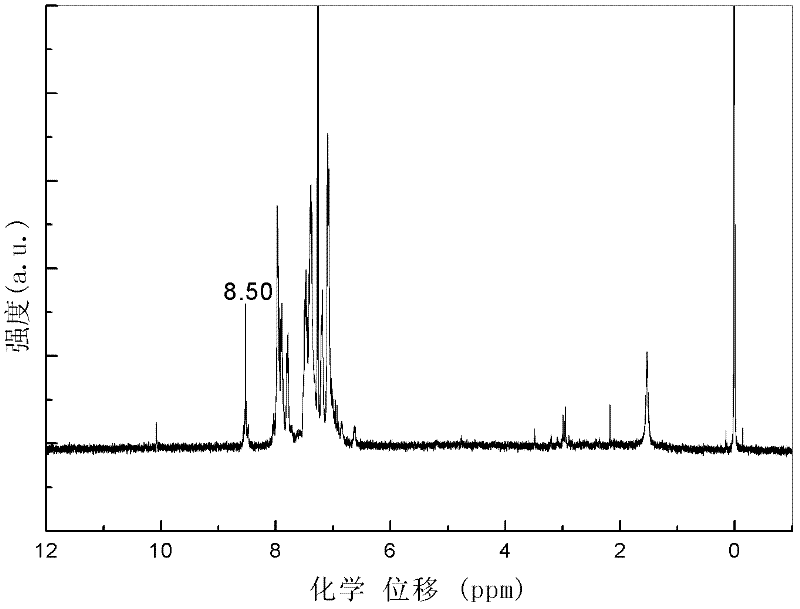

[0036] The carbon nanotube / polySchiff base polymer of this embodiment is dissolved in a chloroform solution, and a film is formed on conductive glass. A transparent electrochromic display device is made by using ca...

specific Embodiment approach 2

[0040] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the poly-Schiff base is an aromatic conjugated poly-Schiff base, and the structural formula is as follows: n=1-100, n is an integer. where R 1 for R 2 for or -CH 2 -CH 2 -CH 2 -, where R' is H or -CH 3 , m=1~8, R " is (CH 2 ) p CH 3 , p is 0-8. Other parameters are the same as in the first embodiment.

[0041] In this embodiment, carbon nanotubes and aromatic conjugated poly-Schiff bases are grafted, and the obtained polymer structure has the comprehensive properties of carbon nanotubes and poly-Schiff bases. Therefore, the carbon nanotube / poly-Schiff base polymer of the present invention can be dissolved in most organic solvents, can be used as a catalyst carrier, has third-order nonlinear characteristics, and has good hole transport performance; it can be used in organic electroluminescent devices , can increase the hole injection density, thereb...

specific Embodiment approach 3

[0042] Embodiment 3: This embodiment differs from Embodiment 1 in that the mass of the aminated carbon nanotubes is 2% to 8% of the mass of both the aromatic diamine monomer and the dialdehyde compound. Other parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com