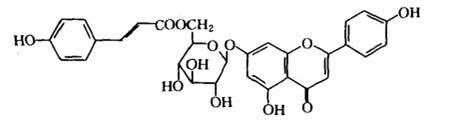

A kind of method of extracting Budeliaoside A from Buddleja

A technology for assimilin A and drunken fish is applied in chemical instruments and methods, preparation of sugar derivatives, production of bulk chemicals, etc., and can solve the problems of few and unpublished methods for extracting assimilin A, and achieve extraction High efficiency, easy industrial production, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The raw material of Buddleia was crushed to 60 mesh, 5kg was added to the supercritical extraction kettle, and liquid CO2 was introduced. The extraction pressure was set at 15MPa and the temperature was 40℃. After the above parameters were reached, the flow rate of liquid CO2 was adjusted to 20kg / h, and the dynamic extraction was carried out for 2 hours. Analyze the extract and discard it under the adjustment of pressure 6MPa and temperature 60℃, then adjust the pressure to 25MPa, and pass the entrainer 60% methanol solution at the same time, flow 3L / h, extract for two hours, analyze the extract, recover the reagent, and obtain the leaching The paste is dissolved in hot water and added to 300g polyamide resin for adsorption. First take 4BV 40% ethanol solution to elute impurities, then 3BV 90% ethanol solution to elute the target components, collect the target components under reduced pressure and concentrate, concentrate After crystallization, the crystalline material wa...

Embodiment 2

[0018] The raw material of Buddleia is crushed to 80 mesh, 5kg is added to the supercritical extraction kettle, liquid CO2 is introduced, the extraction pressure is 30MPa, the temperature is 50℃, after reaching the above parameters, the liquid CO2 flow rate is adjusted to 25kg / h, and the dynamic extraction is 2 hours Analyze the extract and discard it under the adjustment of pressure 8MPa and temperature 50℃, then adjust the pressure to 25MPa, and at the same time pass the entrainer 70% acetone solution, flow rate 2L / h, extract for two hours, analyze the extract, recover the reagent, and obtain the leaching Dissolve the paste in hot water, add it to 200g of polyamide resin for adsorption, first take 4BV of 40% ethanol solution to elute impurities, then use 3BV of 50% ethanol solution to elute the target components, collect the target components under reduced pressure and concentrate, concentrate Crystallize, filter out the crystals, recrystallize with 70% ethanol, and dry to obt...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap