A sludge biophysical combined drying device

A technology combining drying and biophysics, applied in biological sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve the problems of fossil fuel consumption, sludge easy to agglomerate, low heat transfer efficiency, etc., to reduce retention Time, enhanced water removal effect, enhanced heat and mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

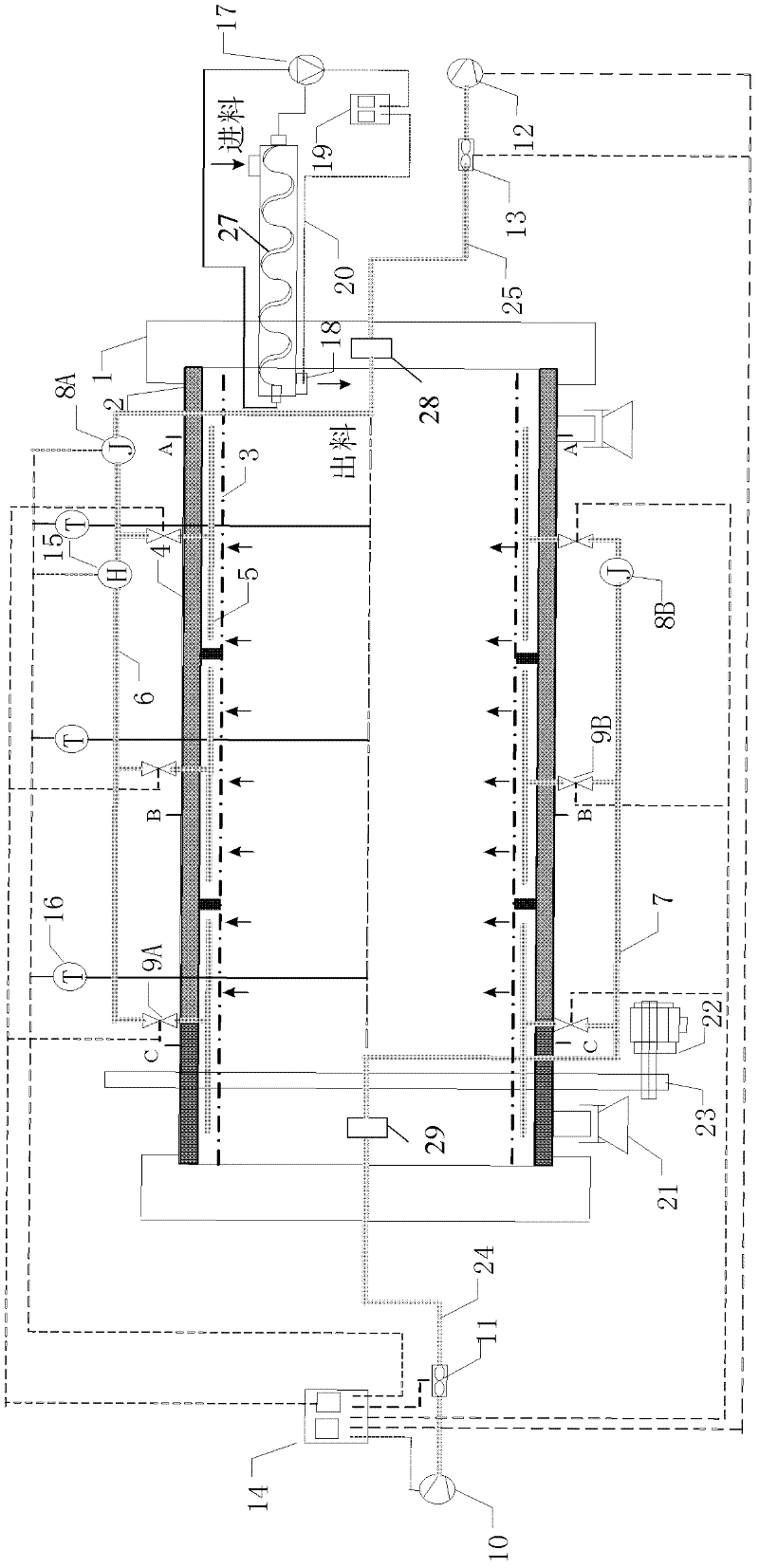

[0022] The structure, working principle and working process of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

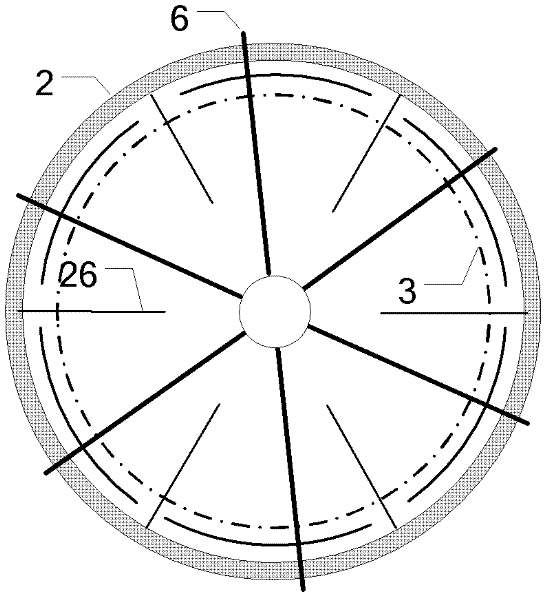

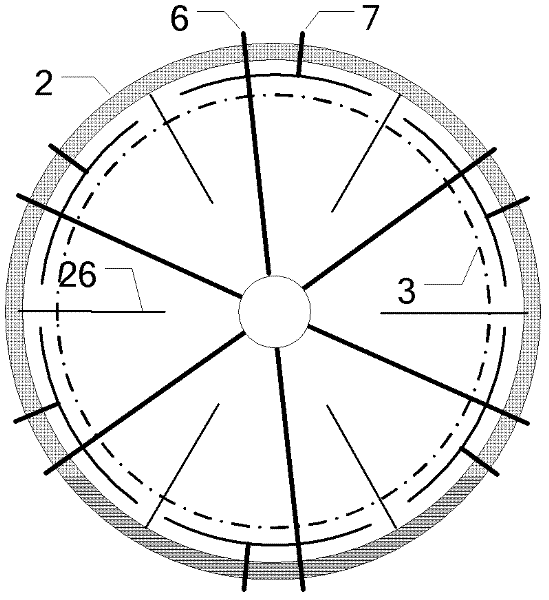

[0023] figure 1The sludge biological-physical combined drying device (sectional view) provided for the present invention. The device includes: a feed system, a drum drying reactor body, an air supply system, an air distribution pipe, and an online temperature and humidity monitoring and feedback system, and is characterized in that the air supply system includes an air supply pump 10 and a flow controller 11 , the main air supply pipe 24 and the multi-channel air supply branch pipe 7, the gas supply main pipe flow controller 11 controls the total flow rate of the air entering the reactor, the main air supply pipe 24 and the multi-channel air supply branch pipe 7 are tightly connected by the rotary joint 29 at the discharge end , each air distribution pipe 5 is connected to the corresponding air su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com