Mechanical transmission of cranes without power source in the work area

A technology of mechanical transmission and cranes, which is applied in the direction of traveling mechanism, transportation and packaging, and load suspension components, etc., can solve the problems of high radiation hazards and easily damaged electrical equipment, so as to improve safety, reduce equipment failure rate, and maintain convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the content, features, and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

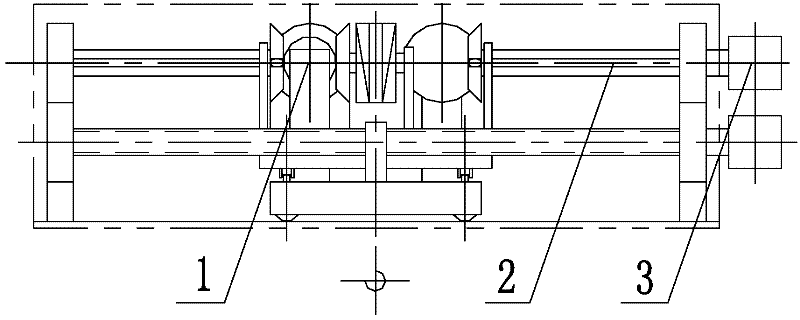

[0017] See Figure 1-Figure 3 , The crane mechanical transmission device without power source in the working area includes the bridge frame 4, the lifting transmission mechanism, the crane operation transmission mechanism and the trolley operation transmission mechanism.

[0018] The lifting transmission mechanism includes: a first lifting transmission shaft 2 connected to a lifting drive motor 3 arranged outside, a first lifting gear pair 1 mounted on the first lifting transmission shaft, and the first lifting gear pair It meshes with the second hoisting gear pair 11 installed on the second hoisting transmission shaft 10. The two ends of the first lifting transmission shaft 2 are respectively fixed to the supporting rail beams of the workshop, and the two ends of the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com