Injection mold rotation non-destructive thread removal mechanism

An injection mold and thread removal technology, which is applied in the field of thread ejection mechanism and non-destructive rotation thread removal mechanism, can solve the problems of increased production cost, product thread damage, thread tooth damage, etc., and achieves cost saving, easy processing, and improved yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

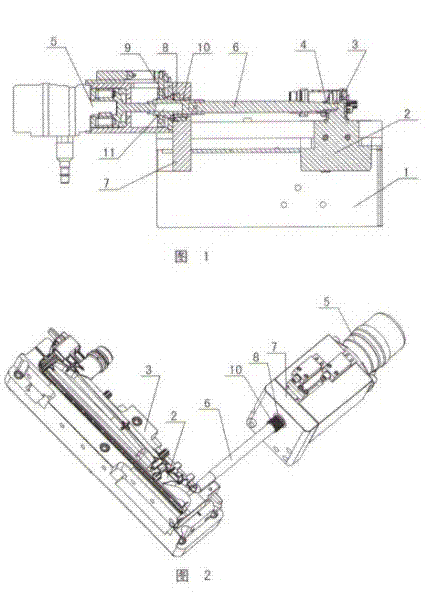

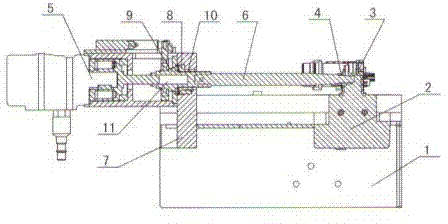

[0010] The invention relates to a non-destructive thread removal mechanism for injection mold rotation, such as Figure 1-Figure 3 As shown, it includes a mold template 1, a mold core 2 is installed on the template, a plastic product 3 is placed on the mold core, a thread 4 is formed on the plastic product, a hydraulic motor 5 is installed on one side of the template 1, and the hydraulic motor is connected to the threaded core through a keyway 6. The head of the thread core 6 matches the thread 4 of the plastic product. It is characterized in that a bracket 7 is installed on the template 1, a thread sleeve 8 is installed in the bracket, and an external thread 10 is formed on the tail of the thread core 6. The external thread 10 is matched with the threaded sleeve 8 . The pitch of the external thread 10 is equal to the pitch of the plastic product thread 4 . The rotary non-destructive thread removal mechanism of this scheme, when working, the hydraulic motor 5 drives the threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com