A clamp for inner support sleeve

A fixture and sleeve technology, used in the field of fixtures for measuring the shape of sleeve parts, can solve problems such as less buffering operation space, damage to the shape of parts, and inconvenience for micro-operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

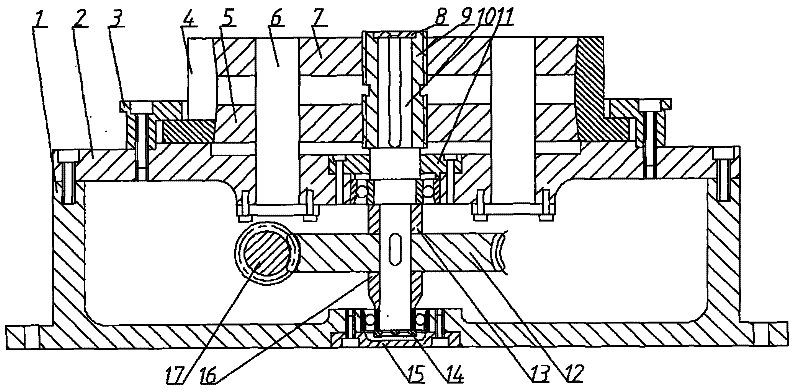

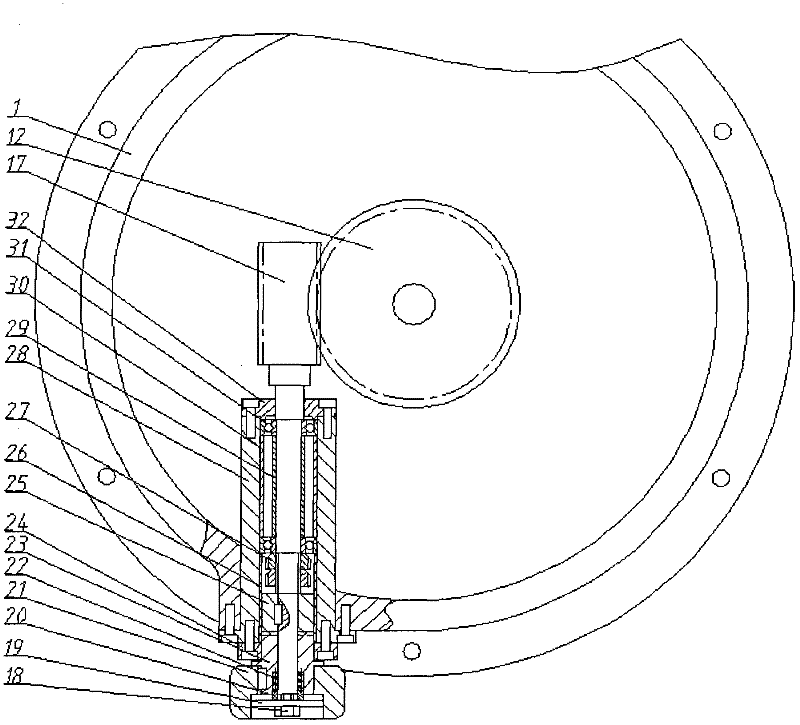

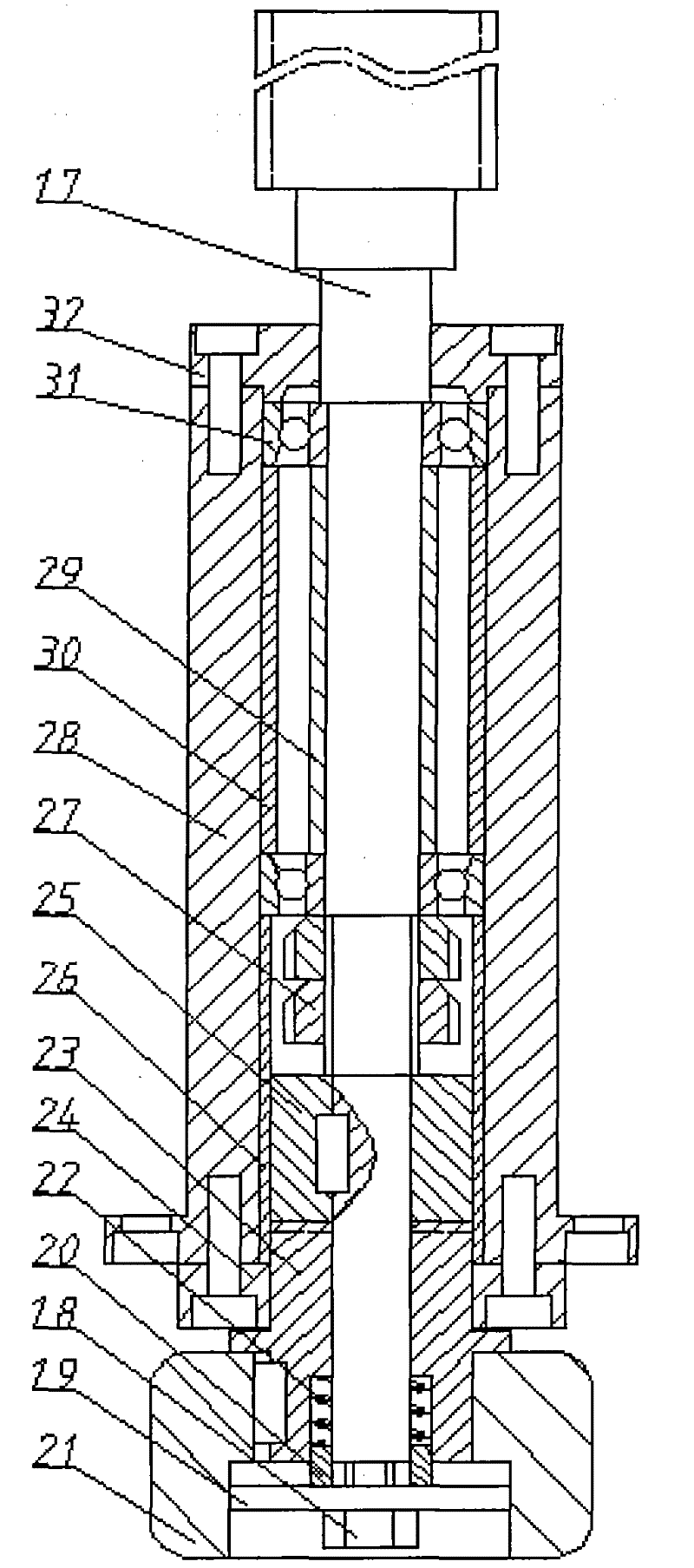

[0028] This example is a fixture for inner-supported sleeve parts, which is used for clamping and testing sleeve parts.

[0029] like figure 1 and figure 2 shown. This example includes a machine base 1, a machine base top cover 2, a shaft 10, a machine base end cover 11, a clamping mechanism, a feed mechanism, a transmission mechanism and a torque limiting mechanism, wherein the machine base top cover 2 is installed on the machine base 1, The base end cover 11 is located in the center hole of the base cover 2, and the bearing seat of the shaft 10 is located in the center hole of the base 1, and is fastened by the bearing end cover 15. The clamping mechanism is installed on the top cover 2 of the machine base, and the feeding mechanism is installed in the machine base 1. The clamping mechanism and the feeding mechanism respectively complete the introduction of clamping sleeve parts and external force. There is an installation platform of the transmission mechanism on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com