A CNC cutting machine

A panel cutting machine and microcomputer technology, applied in the direction of shearing machine control devices, metal processing machinery parts, measuring/indicating equipment, etc., to achieve the effects of eliminating deviations, ensuring processing dimensional accuracy, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

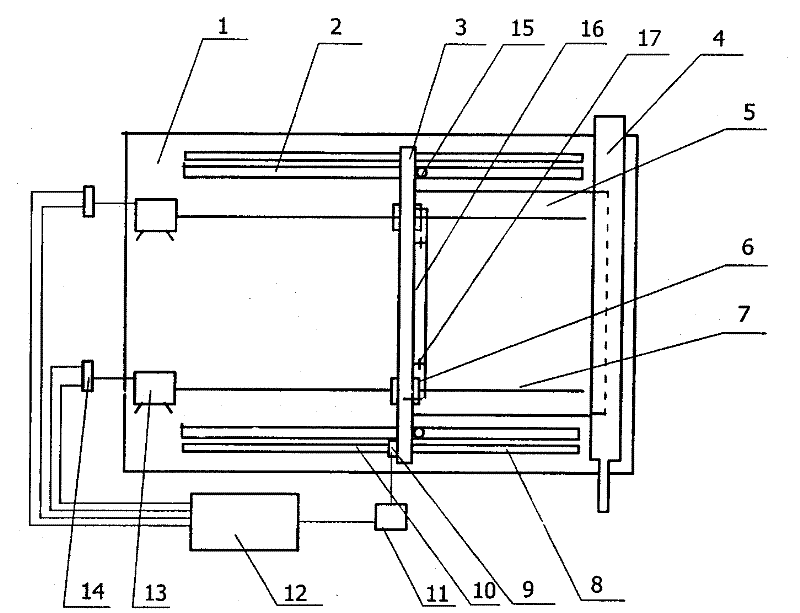

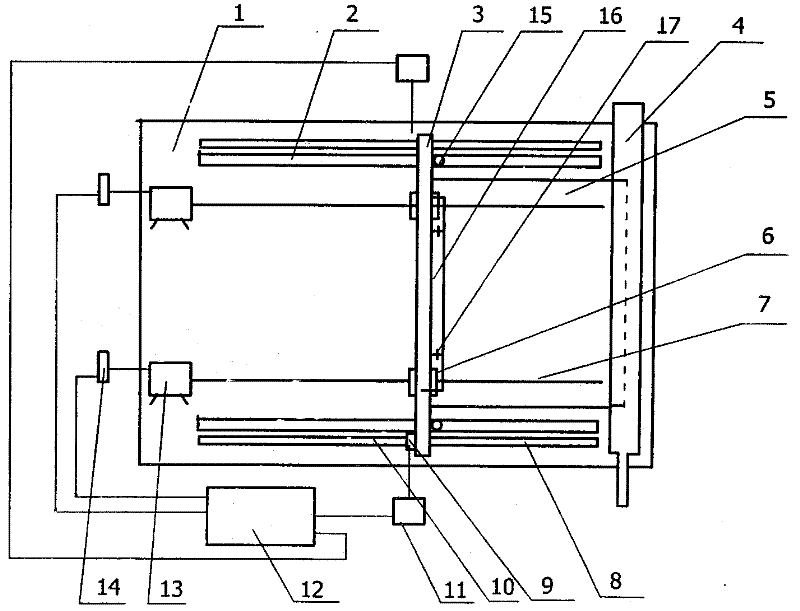

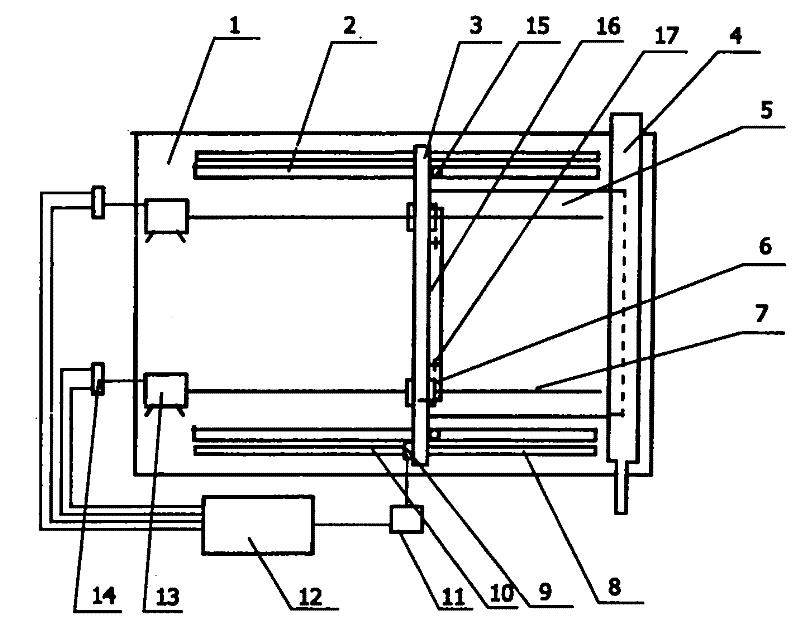

[0022] Such as figure 1 Shown, the embodiment of a kind of numerical control panel cutting machine of the present invention, in figure 1 Among them, a numerically controlled panel cutting machine, comprising: two parallel guide rails 2 are arranged horizontally on the operating table 1, a cutting knife 4 is arranged longitudinally at one end of the guide rail 2, and a grating ruler 10 includes a grating bar 8 and a grating sensor 9 and a grating control converter 11, a mobile positioning rod 3 is arranged longitudinally across the two guide rails 2, the lower part of the mobile positioning rod 3 is fixedly connected with the nut 6 on the ball screw 7, and one end of the ball screw 7 is connected to the servo The motor 13 is connected to the shaft, the servo motor 13 is fixed below one end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com