Powder material and granular material mixing device

A technology of powder materials and granular materials, applied in mixers, mixing methods, mixers with rotating containers, etc., can solve the problems of transmission system and stirring shaft failure, unusability, high power consumption, etc., and achieve stable product quality Reliable, low cost and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

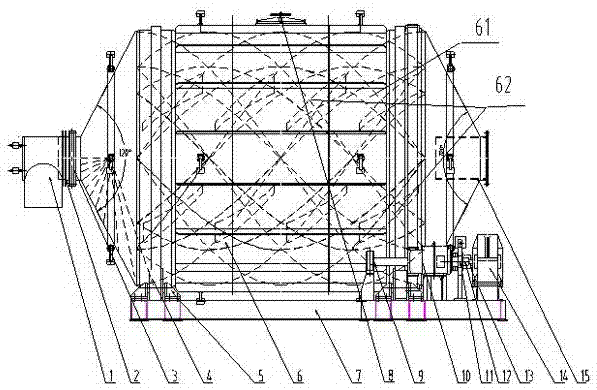

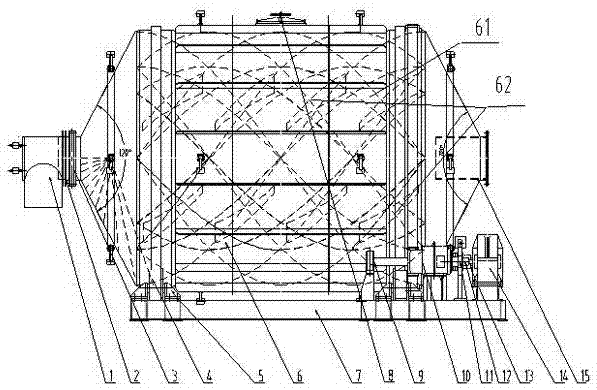

[0022] Attached below figure 1 The optimized embodiment of the present invention will be further elaborated.

[0023] Such as figure 1 As shown, a powder material and granular material mixing device includes a mixing cylinder 6. In this embodiment, the middle of the mixing cylinder 6 is a straight cylinder, and the two ends are conical. There is a support frame inside the straight cylinder, and the mixing cylinder 6 One end of the cone is the outlet 1, and the other end of the cone is provided with an exhaust port 15. The functions of the exhaust port are two: 1. Balance the force of the other end of the cone; 2. Set up the exhaust port. When feeding, such as If the mixing cylinder 6 is in a state where there is no other exhaust port except the feed port, the dust will recoil out of the equipment through the feed port, polluting the environment and wasting products. After opening the exhaust port and matching the filter bag, the air has a discharge channel, and the dust is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com