Wiring parts for automotive rotating electrical machines

A technology for rotating electrical machines and wiring components, which is applied in the direction of electrical components, electric components, electromechanical devices, etc., and can solve the problems of reducing bending workability, increasing the outer diameter of wiring components, and increasing the protrusion amount of protrusions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

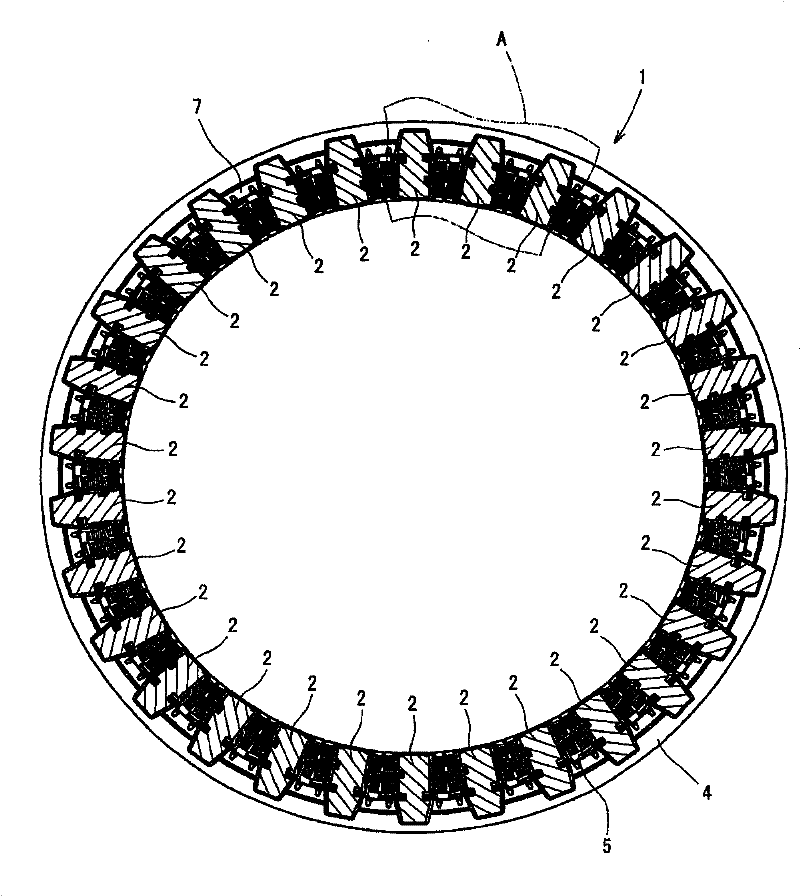

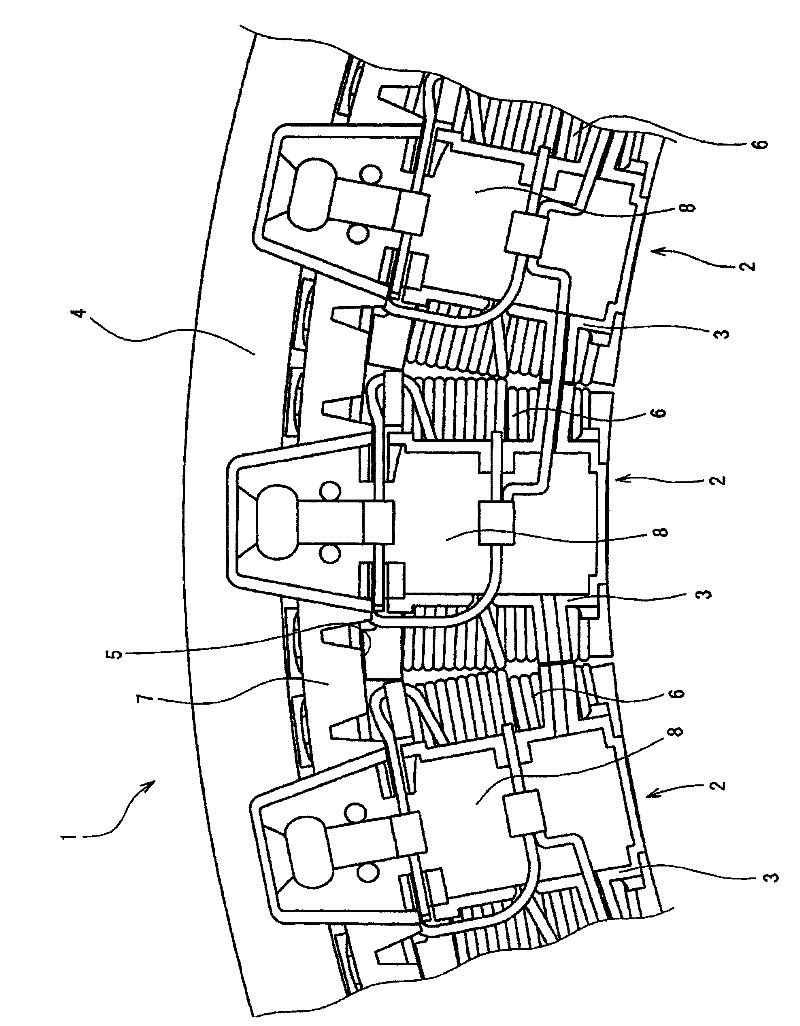

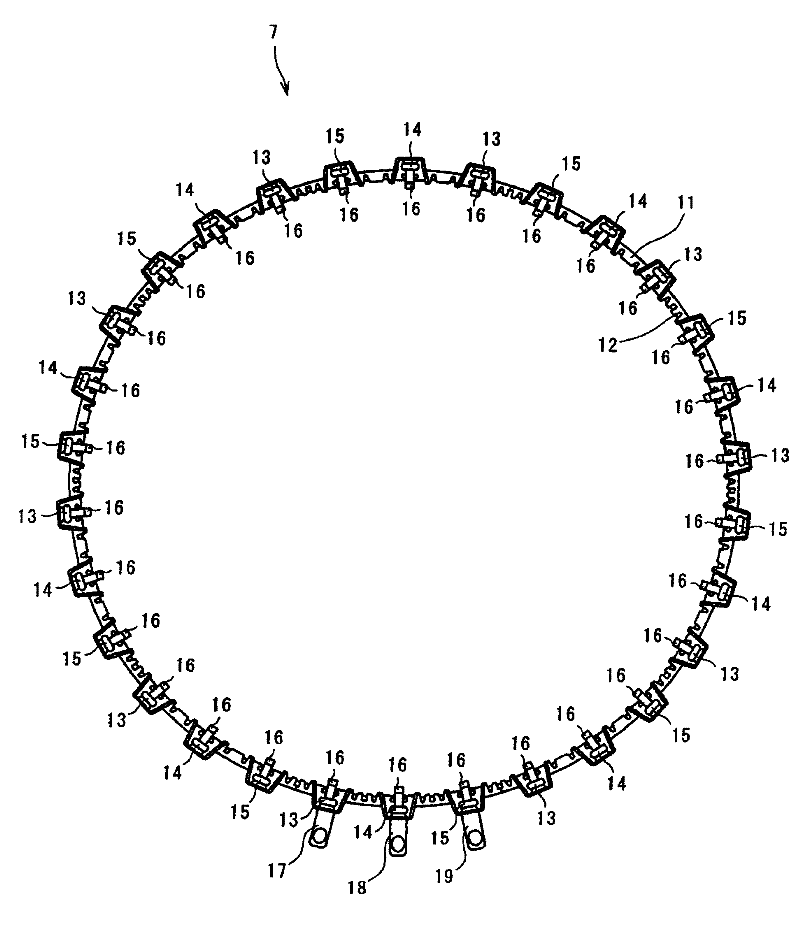

[0028] Next, a rotary electric machine for a vehicle having a wiring member will be described.

[0029] figure 1 shows a plan view representing a stator 1 in a rotating electrical machine for a vehicle according to an embodiment of the present invention, and, figure 2 show figure 1 Partial enlarged top view of part A of the stator shown. For explanatory purposes, figure 2 The stator 1 shown is not filled with the insulating resin material described below. The segmented iron core 2 is composed of layered silicon steel sheets, the resin casing 3 is installed on the layered silicon steel sheets, and, in this embodiment, ten segmented iron cores 2 are arranged on the inner peripheral surface of the stator housing 4 5 to form a single-phase core. In this embodiment, a total of thirty segmented iron cores 2 are used to form a three-phase iron core. An enamelled copper wire is wound around each segmented core 2 to form a coil 6 . A slip ring 7 for supplying power to each coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com