A goods supply device for a shelf of an automatic vending machine

The technology of a vending machine and a supply device is applied in the direction of coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, coinless or similar appliances, etc., which can solve the problem of heavy structure, Problems such as high production cost and large space occupation, achieve the effect of reducing complexity, simple structure and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention will be further described:

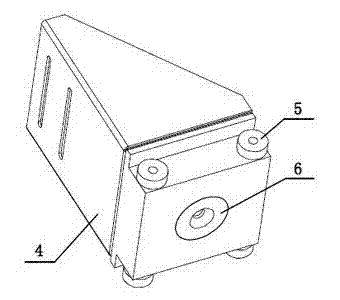

[0021] A goods supply device for a shelf of an automatic vending machine, comprising a guide rail 7, a goods push plate 4 and a slider 2, the guide rail 7 is a rectangular column, which is convenient for storing goods and placing the goods push plate 4, and the central cavity 8 of the guide rail The cross-section is a rounded rectangle, the shape of the slider 2 matches the center cavity 8 of the guide rail, the slider 2 is slidably arranged in the center cavity 8 of the guide rail and closely matched with the wall of the center cavity of the guide rail, which is equivalent to a piston device; The plate 4 is slidingly arranged on the upper surface of the guide rail 7, the center of the bottom of the cargo push plate 4 is provided with a first high magnetic steel 6, the center of the upper part of the slider 2 is provided with a second high magnetic steel 1, and the first hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com