A new type of pump cover for radial variable displacement plunger pump with disc flow distribution

A technology of variable plunger and flow distribution, which is applied to variable displacement pump components, components of pumping devices for elastic fluids, pump components, etc., and can solve difficult processing, irreparable, complex structure of plunger pump pump cover, etc. problem, to achieve the effect of strong wear resistance, easy mass production and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

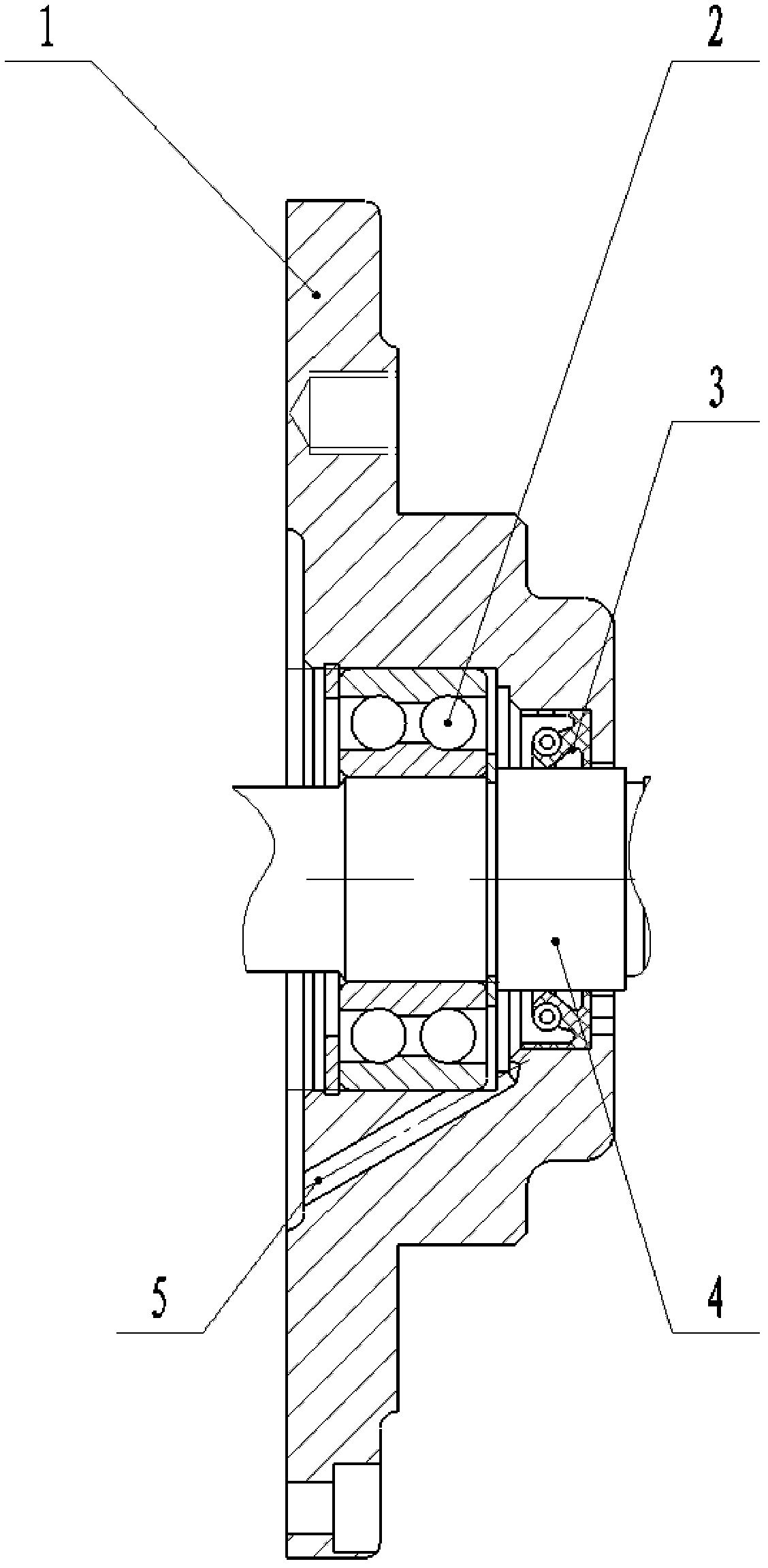

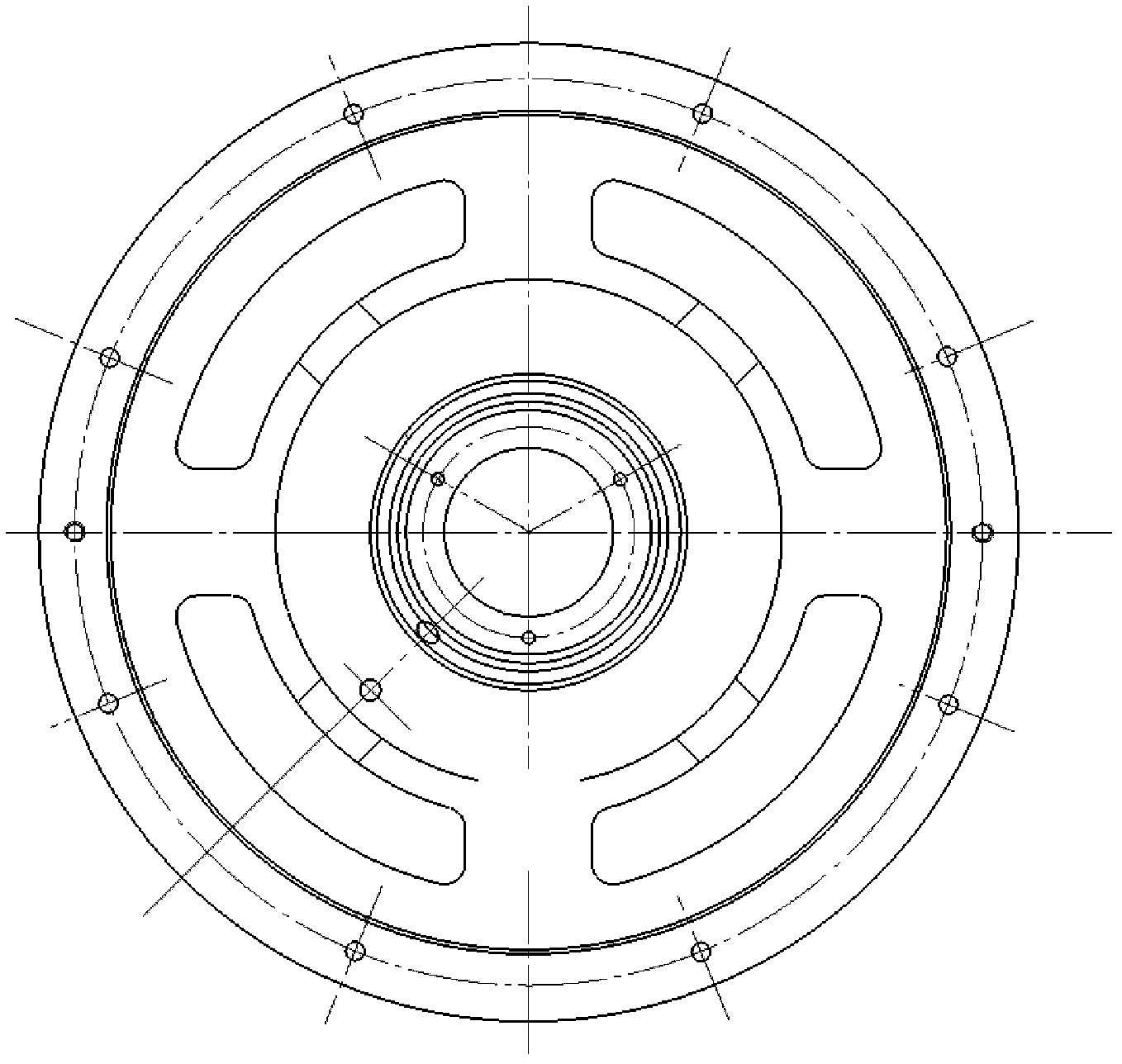

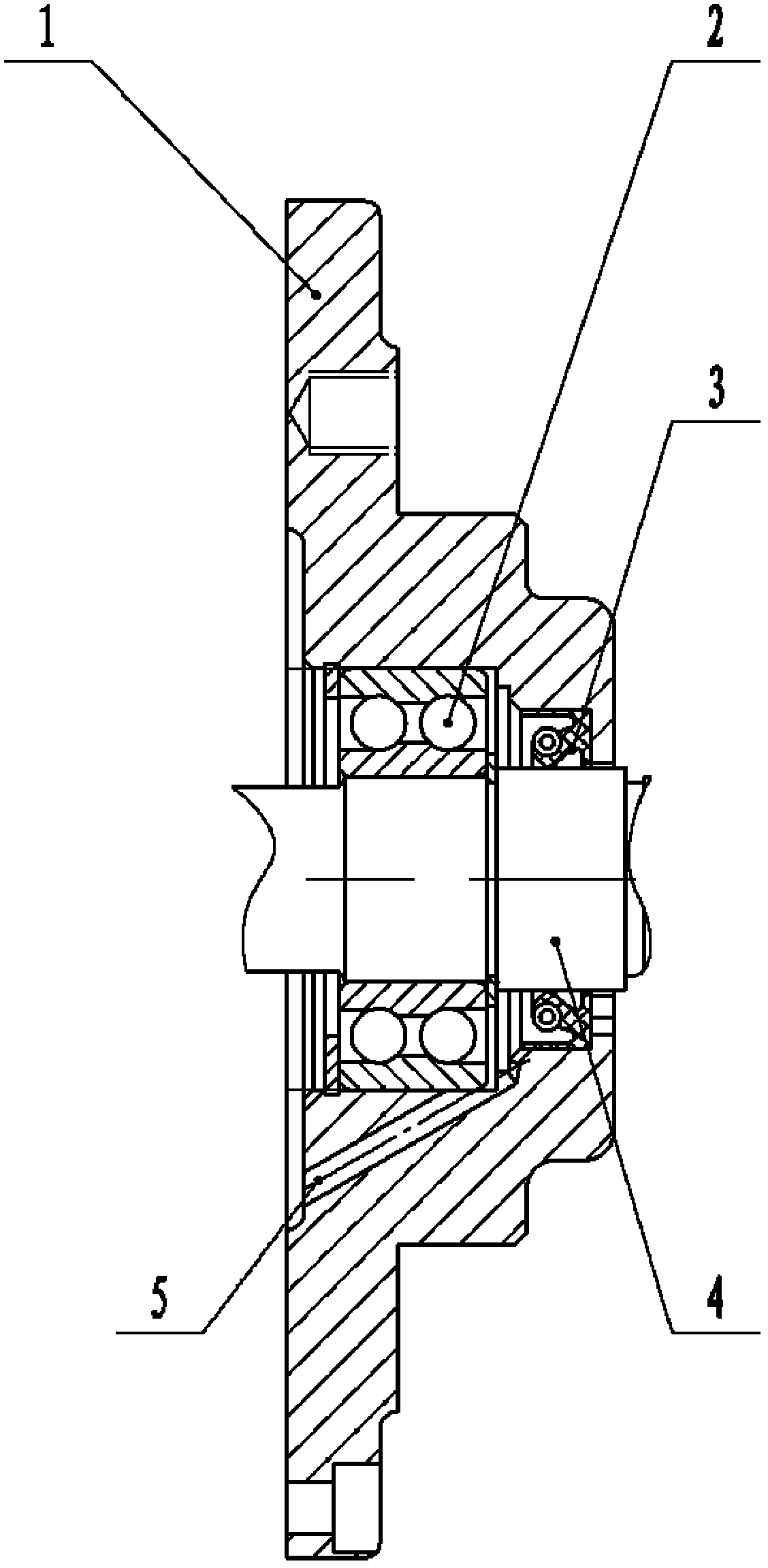

[0010] Depend on figure 1 and figure 2 It can be seen that the solution adopted by the present invention to solve the technical problems is to provide a new type of pump cover for the radially variable plunger pump with disc flow distribution. , the transmission shaft 4 is fixed in the pump cover body 1 through the shaft seal 3 and the transmission bearing 2 .

[0011] When in use, it is assembled with the pump body, flow distribution plate, stator, rotor, plunger assembly, control valve seat, etc. to form a plate distribution radial piston pump with a valve core self-distribution servo structure. The hydraulic oil enters the pump body from the inlet and is sealed by the pump cover. The rotor is rotated through the transmission shaft, and the plunger is driven to squeeze the hydraulic oil to form high-pressure oil. The high-pressure oil is formed in the cavity of the pump body and sent to the pump body to complete the conversion from low-pressure oil to High pressure oil pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com