Method for producing enzymatic rice bran red koji wine

A production method, the technology of red yeast rice wine, applied in the field of wine making, to achieve the effect of enhancing immunity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

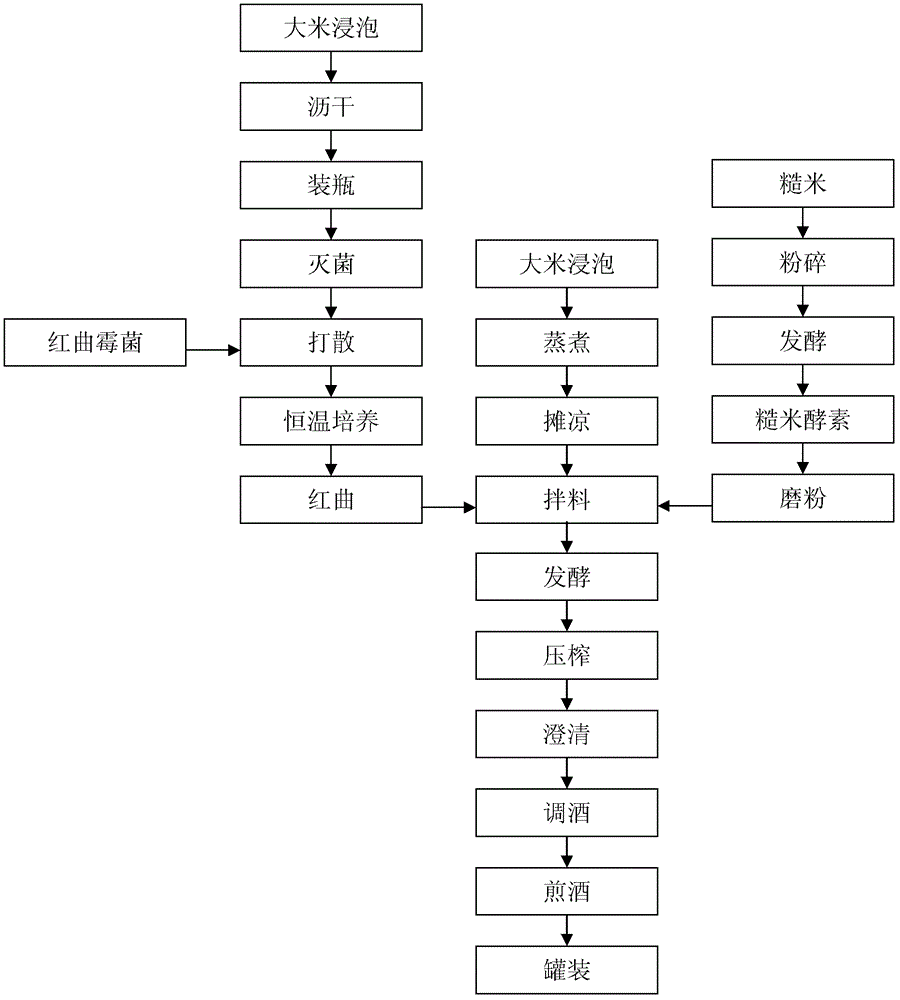

Image

Examples

Embodiment 1

[0026] Embodiment 1: the production method of brown rice enzyme red koji wine is: a. rice soaking: rice soaking water reaches domestic water standard, rice soaking water surface is higher than rice surface 10~15cm, rice soaking time 12-24h, rice soaking water temperature 20- 30°C; b. steaming rice: steam the soaked rice under normal pressure until it is cooked and not rotten; c. cooling: the rice is cooled to 35-55°C; d. feeding: the ratio of brown rice enzyme to rice in raw materials is 1: 3. The amount of red yeast rice added is 7% of the raw material, the optimum amount of yeast added is 1.0%, and the amount of water added is 1.2 times that of the raw material; 20 days; f. Squeeze: After the fermentation is completed, put the fermented mash into the press for pressing; g. Clarify and filter: the obtained wine is allowed to stand for 2 to 3 days for clarification, and then filtered through a wine filter; h. Wine mixing: flavoring and blending the filtered wine; i. frying win...

Embodiment 2

[0028] Embodiment 2: the production method of brown rice enzyme red koji wine is: a. rice soaking: rice soaking water reaches domestic water standard, rice soaking water surface is higher than rice surface 10~15cm, rice soaking time 12-24h, rice soaking water temperature 20- 30°C; b. steaming rice: steam the soaked rice under normal pressure until it is cooked and not rotten; c. cooling: the rice is cooled to 35-55°C; d. feeding: the ratio of brown rice enzyme to rice in raw materials is 1: 3. The amount of red yeast rice added is 12% of the raw material, the optimum amount of yeast added is 1.5%, and the added amount of water is 1.6 times that of the raw material; 20 days; f. Squeeze: After the fermentation is completed, put the fermented mash into the press for pressing; g. Clarify and filter: the obtained wine is allowed to stand for 2 to 3 days for clarification, and then filtered through a wine filter; h. Wine mixing: flavoring and blending the filtered wine; i. frying wi...

Embodiment 3

[0030] Embodiment 3: the production method of brown rice enzyme red koji wine is: a. rice soaking: rice soaking water reaches domestic water standard, rice soaking water surface is higher than rice surface 10~15cm, rice soaking time 12-24h, rice soaking water temperature 20- 30°C; b. steaming rice: steam the soaked rice under normal pressure until it is cooked and not rotten; c. cooling: the rice is cooled to 35-55°C; d. feeding: the ratio of brown rice enzyme to rice in raw materials is 1: 3. The amount of red yeast rice added is 8% of the raw material, the optimum amount of yeast added is 1.1%, and the amount of water added is 1.3 times that of the raw material; 20 days; f. Squeeze: After the fermentation is completed, put the fermented mash into the press for pressing; g. Clarify and filter: the obtained wine is allowed to stand for 2 to 3 days for clarification, and then filtered through a wine filter; h. Wine mixing: flavoring and blending the filtered wine; i. frying win...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com