Imaging box chip, imaging box and identification method for imaging box

An imaging box chip, imaging box technology, which is applied in the direction of electric recording process applying charge pattern, equipment for applying electric recording process of charge pattern, electric recording technique, etc. Cost and other issues, to achieve the effect of simplifying product structure, avoiding high precision requirements, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

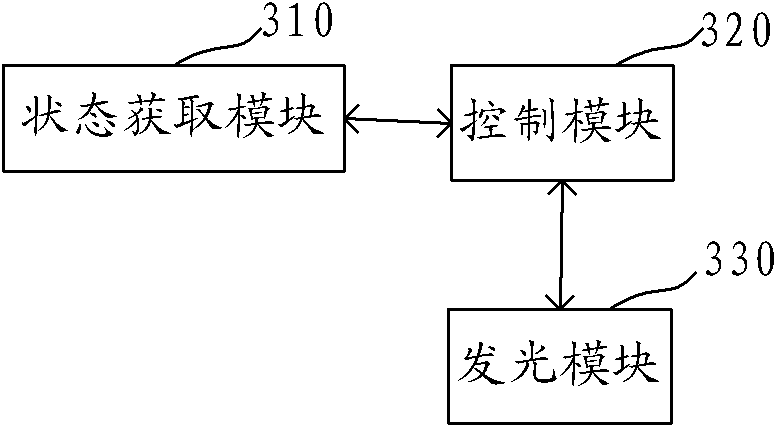

[0030] image 3 The structural diagram of the imaging cartridge chip provided in Embodiment 1 of the present invention, the imaging cartridge chip is a chip installed on the imaging cartridge, and usually records the basic information of the imaging cartridge, such as model, production date, toner type and toner amount and other data. The imaging device identifies the imaging cartridge by interacting with the imaging cartridge chip, and also updates the information in the chip by writing data into the imaging cartridge chip. The imaging cartridge chip provided in this embodiment at least includes a status acquisition module 310 and a control module 320 . Wherein, the status acquiring module 310 is used to acquire the usage status information of the imaging box; the control module 320 is connected with the status acquiring module 310, and is used to generate a light control signal corresponding to the usage status information of the imaging box according to the optical identif...

Embodiment 2

[0049] Image 6 It is a schematic diagram of the structure of the imaging cartridge chip provided by Embodiment 2 of the present invention. This embodiment may be based on the foregoing embodiments, and specifically provides a method for obtaining the amount of toner. The dose acquisition unit 310 a in the state acquisition module 310 may include: a dose detection subunit 311 , configured to detect the toner amount from the information exchanged between the imaging cartridge chip and the imaging device, and provide it to the control module 320 .

[0050] The dose detection subunit is mainly used for reading and writing relevant data when the imaging device communicates with the imaging box, and can complete the reading and writing of information under the control of the control module. The information communicated between the imaging device and the imaging cartridge may include the remaining amount of toner, the color of the toner, the date when the imaging cartridge was first...

Embodiment 3

[0052] Figure 7 It is a schematic structural diagram of the imaging cartridge chip provided by Embodiment 3 of the present invention. This embodiment may be based on the foregoing embodiments, and specifically provides another way of obtaining the amount of toner. The dose acquisition unit 310 a in the state acquisition module 310 may include: a consumption detection subunit 312 and a dose estimation subunit 313 . The consumption detection subunit 312 is used for detecting the consumption information from the information exchanged between the imaging cartridge chip and the imaging device. For example, the number of printed pages, etc.; the dose estimation subunit 313 is used to calculate the toner amount according to the consumption information and preset estimation rules, and provide it to the control module 320 .

[0053] The preset estimation rule may be, for example, roughly how much toner is needed to print one page, estimate the used toner according to the number of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com