A Control Method for Coiler Tracking Loss Reconstruction in Hot Rolling Line

A control method and wire coil technology, applied in the direction of rolling mill control devices, metal rolling, metal rolling, etc., can solve the problems of finishing rolling and coiling tracking loss, affecting product qualification rate, and coiling scrap steel, etc., to improve qualified rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below by embodiment.

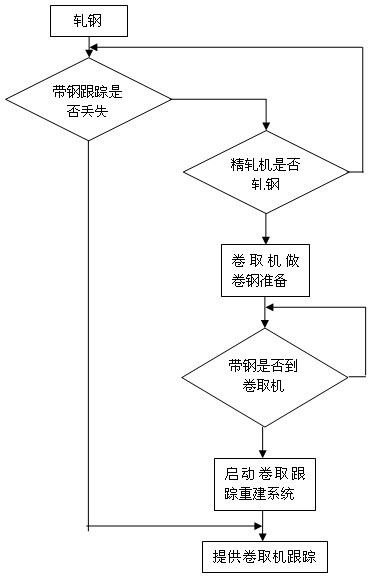

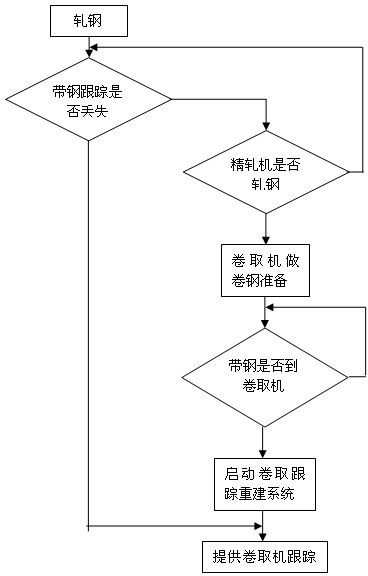

[0013] The control method for coiling tracking loss and reconstruction of hot rolling line is to automatically identify tracking loss by the computer system and its software on the basis of not destroying the original tracking process, and automatically start the tracking reconstruction system to provide accurate tracking signals for the coiler , A method for realizing the normal steel coiling of the coiler. Its control methods are as follows:

[0014] A. Determine the loss of tracking of the strip being rolled by the finishing coiler;

[0015] B. Use the rolling signal of the rolling mill without tracking as the trigger signal for the speed-up of the coiler reel and the auxiliary roll to ensure the normal speed-up of the reel and the auxiliary roll;

[0016] C. Determine that the strip steel has arrived at the coiler, and when the strip steel arrives at the coiler, start the coiling tracking recon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com