Device for collecting fine sand of a rock

A technology for recycling device and rock, applied in wet separation, sustainable waste treatment, solid waste management, etc., can solve the problems of insufficient recovery of rock fine sand, insufficient use of rock fine sand, and reduced filling properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

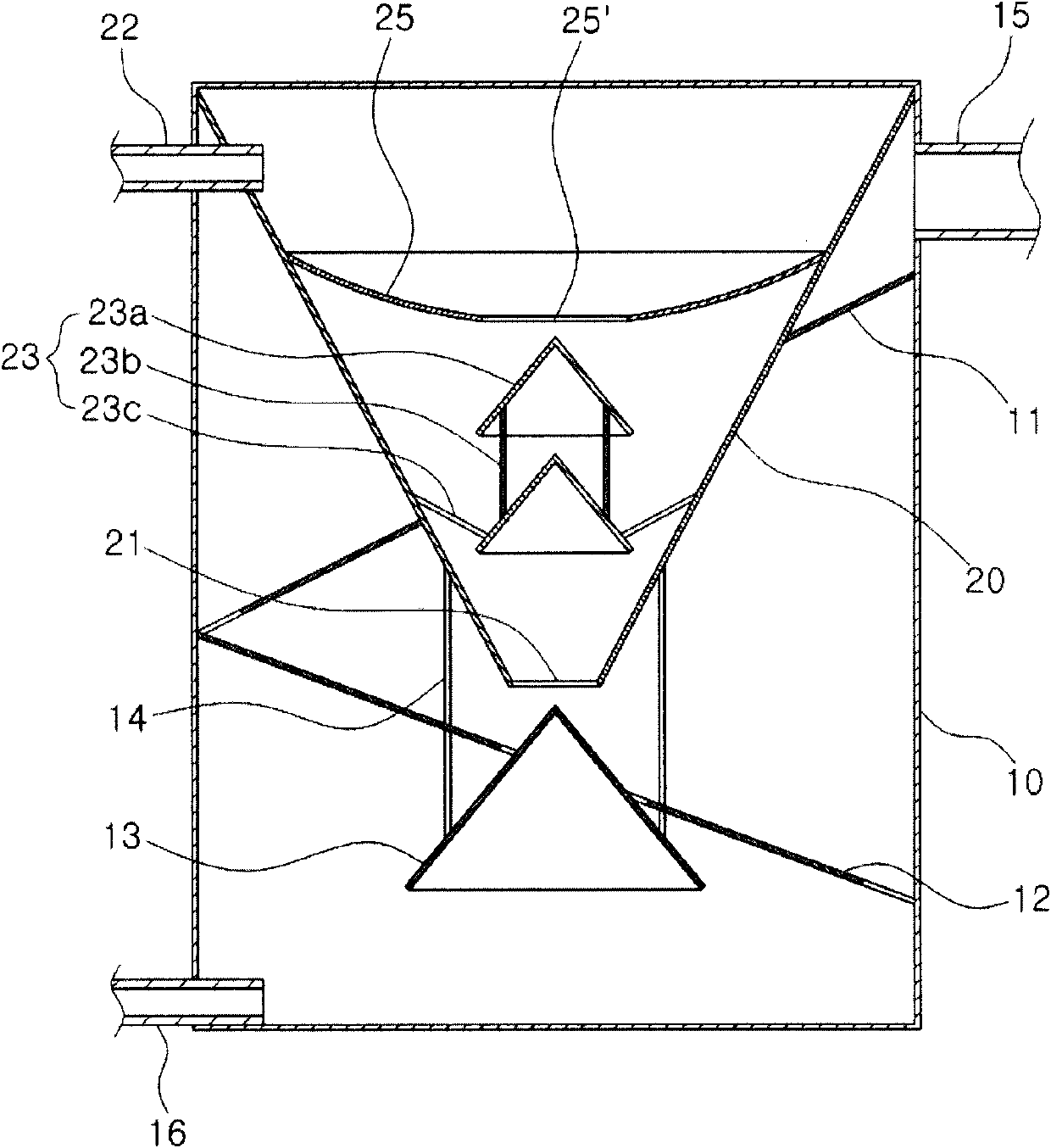

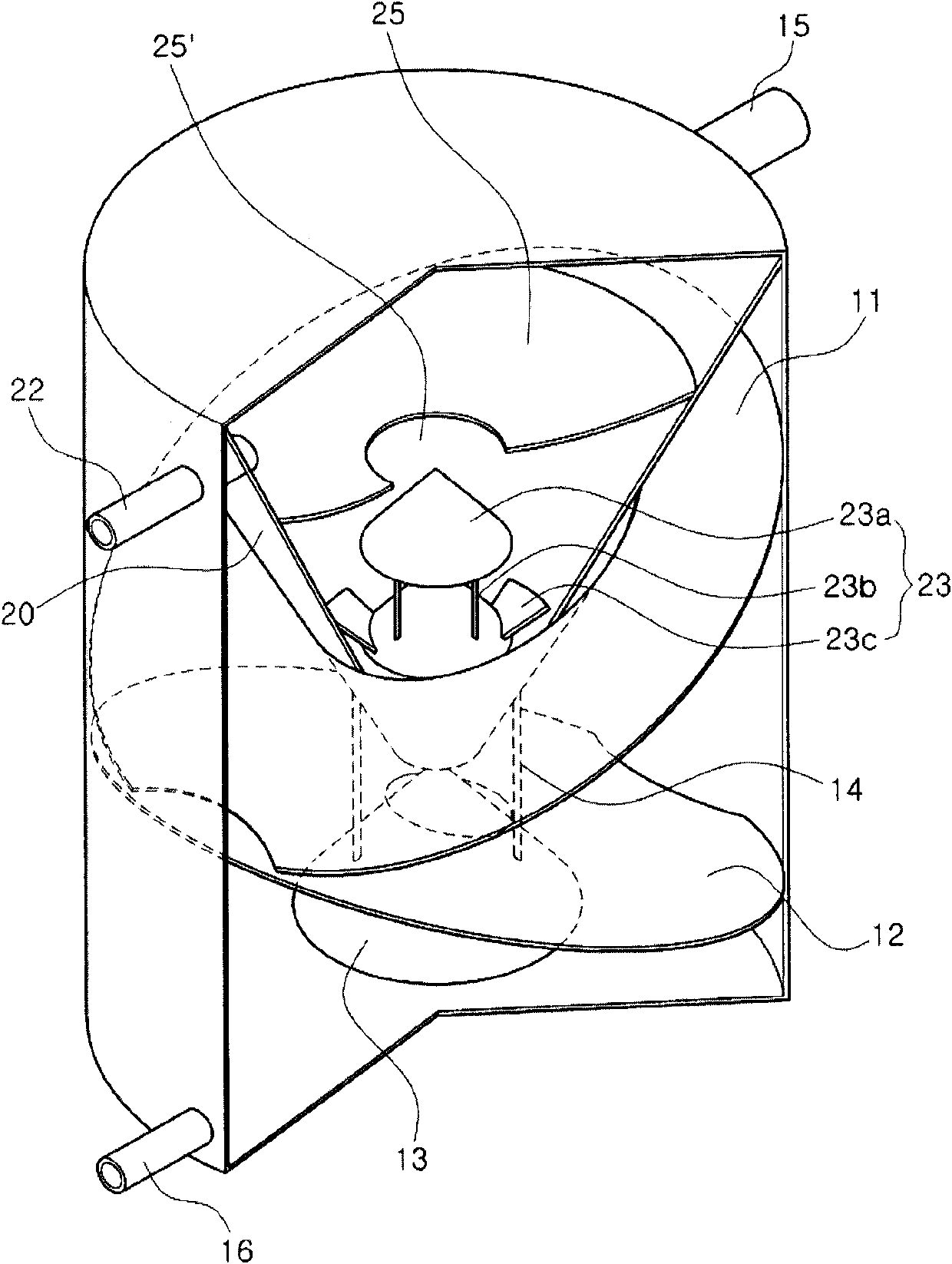

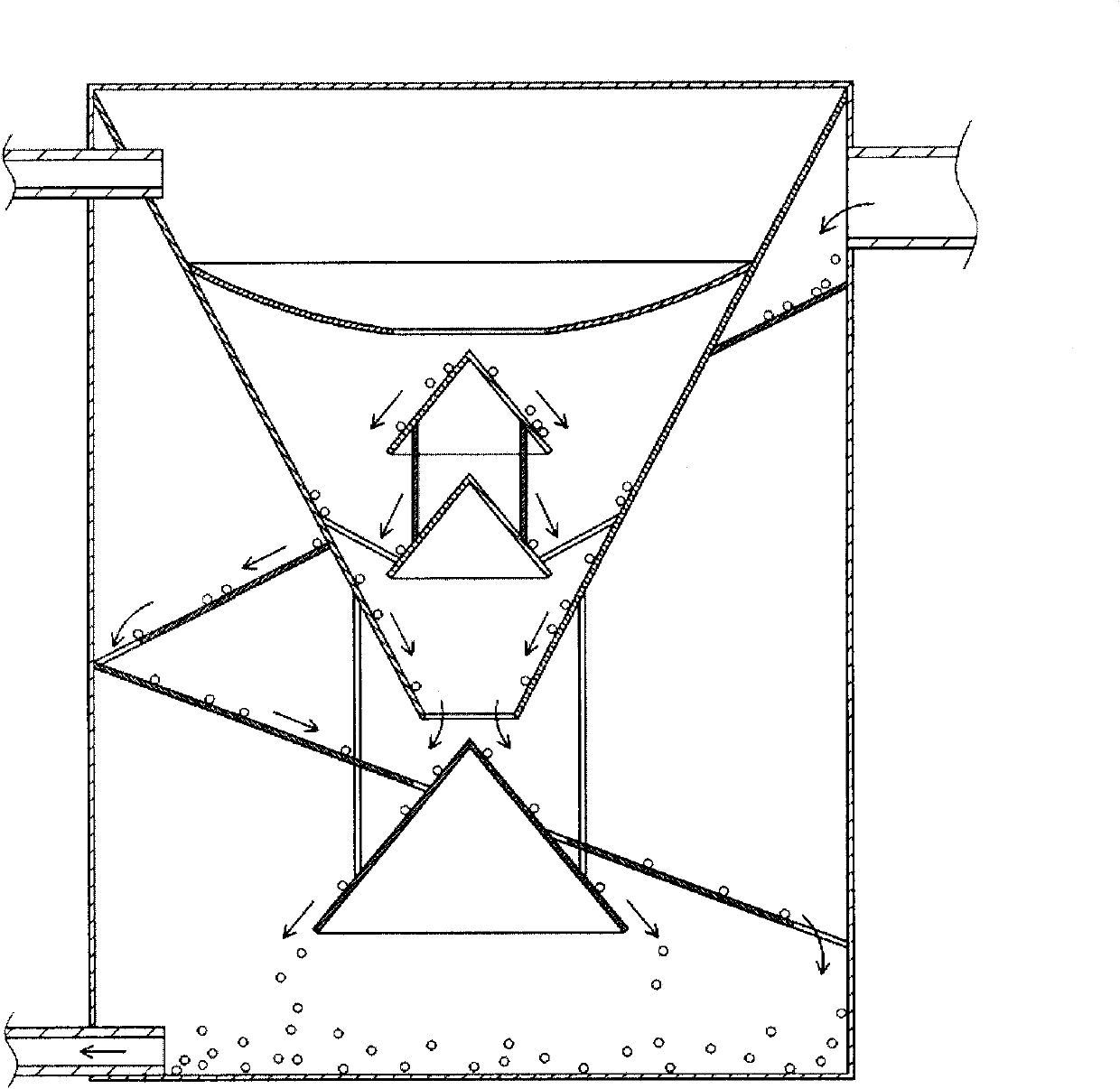

[0022] Next, the rock fine sand recovery device of the present invention is described as follows with reference to the accompanying drawings.

[0023] According to the rock fine sand recovery device of the present invention such as figure 1 and figure 2 As shown, it includes: a cylindrical body 10; a first inclined plate 11 is obliquely arranged inside the above-mentioned body 10, and its lower end is spaced apart from the inner wall of the above-mentioned body 10; a second inclined plate 12 is arranged inside the above-mentioned body 10 It is inclined to the opposite direction of the above-mentioned first inclined plate 11, and its lower end is spaced apart from the inner wall and bottom surface of the above-mentioned body 10; the upper end of the conical water chamber 20 is fixed on the upper edge of the above-mentioned body 10, and the lower end A hole 21 is provided; a barrier plate 25 is arranged on the upper side of the above-mentioned water chamber 20, and a hole 25' ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com