A new type of milling device

A grinding device and powder grinding technology, applied in the field of grinding devices, can solve the problems of complex structure of the grinding device, uneven particle size, poor grinding effect, etc., to reduce maintenance costs and operating costs, achieve uniform powder, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

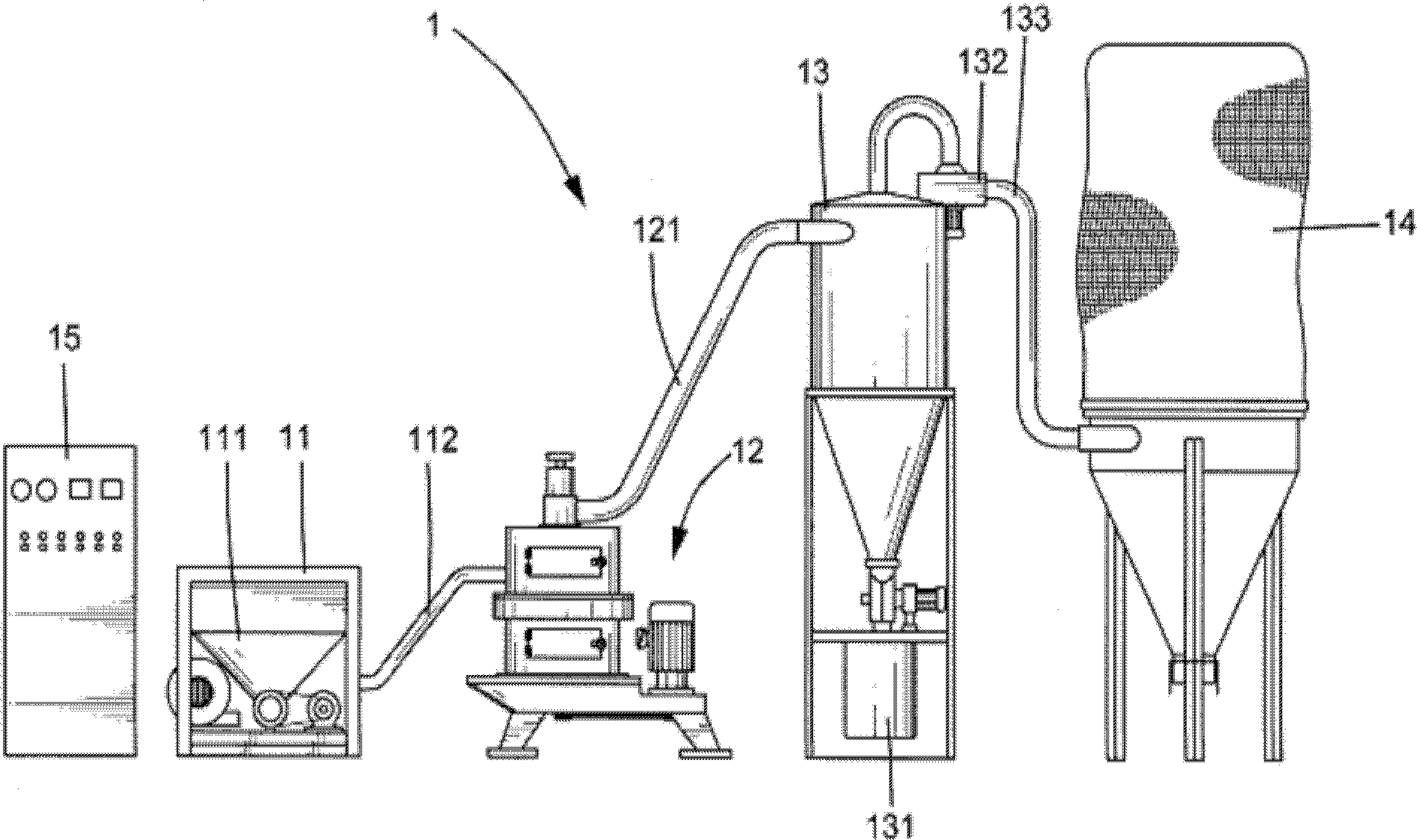

[0025] see figure 1 , shows a schematic diagram of the novel milling device of the present invention. The milling device 1 comprises a feeding device 11 , a grinder 12 , a hopper 13 , a dust collector 14 and a control device 15 .

[0026] Wherein, the feeding device 11 is provided with a funnel 111 for processing raw materials to enter, and the feeding device 11 is connected to the grinding machine 12 through the first pipeline 112, so that the processing raw materials are sent into the grinding machine 12 through the first pipeline 112, and the grinding machine 12 The processed raw material is ground to form a powder.

[0027] The grinding machine 12 is connected to the feeding chute 13 through the second pipeline 121, and the bottom of the feeding chute 13 is provided with a collector 131, and the collecting device 131 collects the powder collected by the second pipeline 121, and the feeding chute 13 The upper end of the exhaust fan 132 is provided with an exhaust fan 132,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com